Exhaust gas purification device for internal combustion engine

An exhaust gas purification device and internal combustion engine technology, which is applied in the direction of exhaust devices, internal combustion piston engines, noise reduction devices, etc., can solve the problems of catalyst performance deviation, time-consuming, and easy deterioration, and achieve reliable purification, easy installation, and improved utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0064] A first embodiment of the present invention will be described below with reference to the drawings.

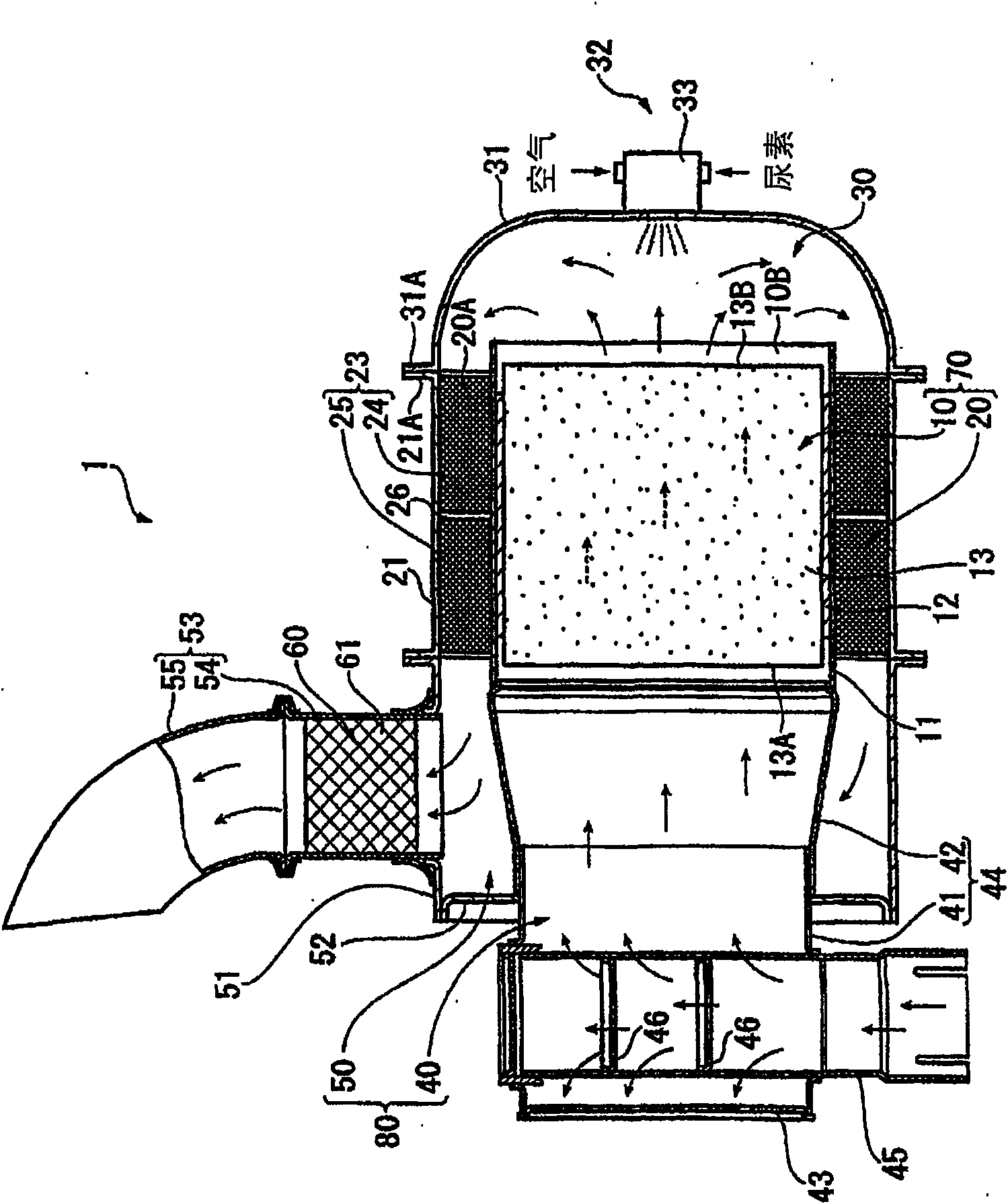

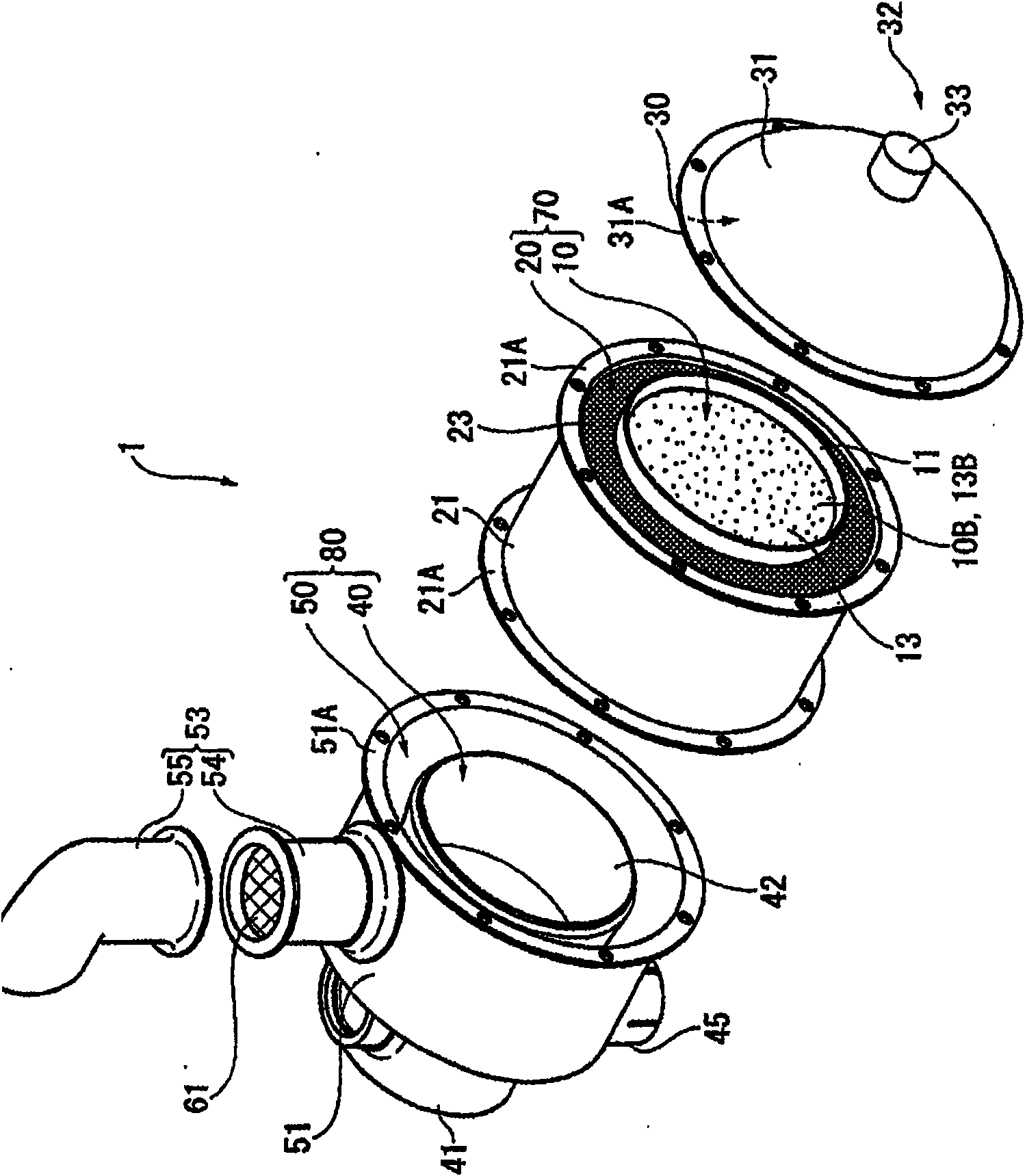

[0065] figure 1 It is a sectional view showing the whole of the exhaust gas purification device 1 for an internal combustion engine according to this embodiment, figure 2 is its exploded perspective view. In addition, a diesel engine is mainly assumed as the internal combustion engine of this embodiment.

[0066] The exhaust gas purification device 1 is installed in the exhaust flow path of the diesel engine, which is a device for trapping particulates contained in the exhaust gas and reducing the emission amount of NOx discharged into the atmosphere, and the exhaust gas purification device 1 also serves as an exhaust gas silencer. Moreover, this exhaust gas purification device 1 is suitable for installation in construction machines such as hydraulic excavators, bulldozers, and wheel loaders.

[0067] Such as figure 1 and figure 2 As shown, the exhaust gas purif...

no. 2 approach

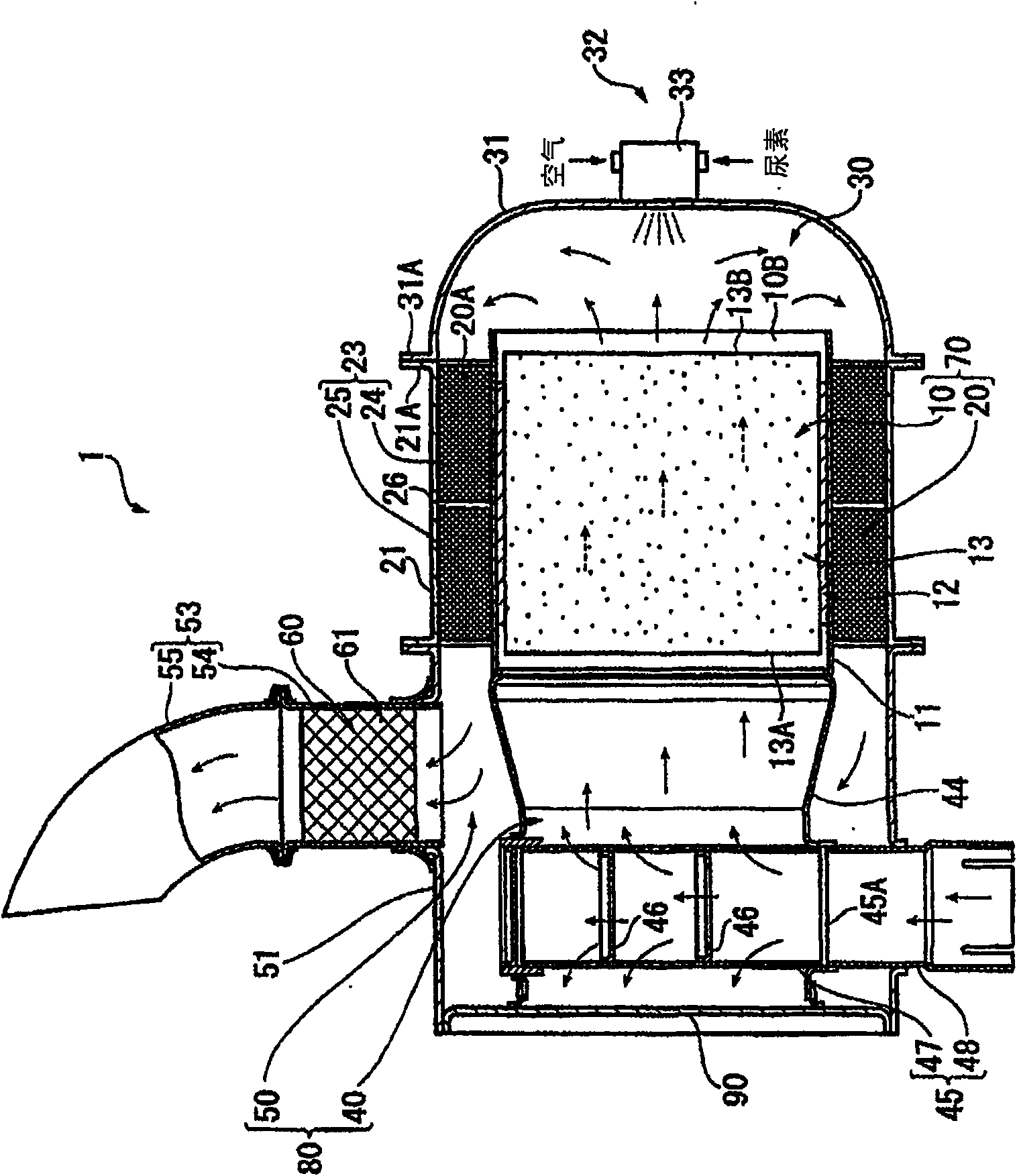

[0108] Next, a second embodiment will be described. In the following description, the same reference numerals are assigned to the same parts as those already described, and the description thereof will be omitted.

[0109] As a second embodiment of the present invention, image 3 A further embodiment of the inlet chamber 40 and the outlet chamber 50 of the exhaust gas purification device 1 is shown.

[0110] In the present embodiment, one end side of the inlet chamber 40 and the outlet chamber 50 is closed by a common side wall portion 90 . However, it is of course also possible to provide the side wall portion separately.

[0111] Furthermore, by arranging the entire inner cylinder 44 inside the outer cylinder 51 , the inlet chamber 40 is completely covered by the outlet chamber 50 , and the inlet pipe 45 provided on the inlet chamber 40 penetrates the peripheral wall of the outer cylinder 51 . In addition, the inlet chamber 40 is downsized to the extent that it can be acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com