Vacuum-pumping method and apparatus thereof

A vacuuming device and vacuuming technology, which is applied to liquid variable volume machinery, machines/engines, mechanical equipment, etc., can solve the problems of low utilization rate of heat energy, difficult to operate, and reduce the vacuum degree of the interlayer, and achieve high utilization rate of heat energy. , not easy to run off, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments according to the present invention will be described with reference to the accompanying drawings.

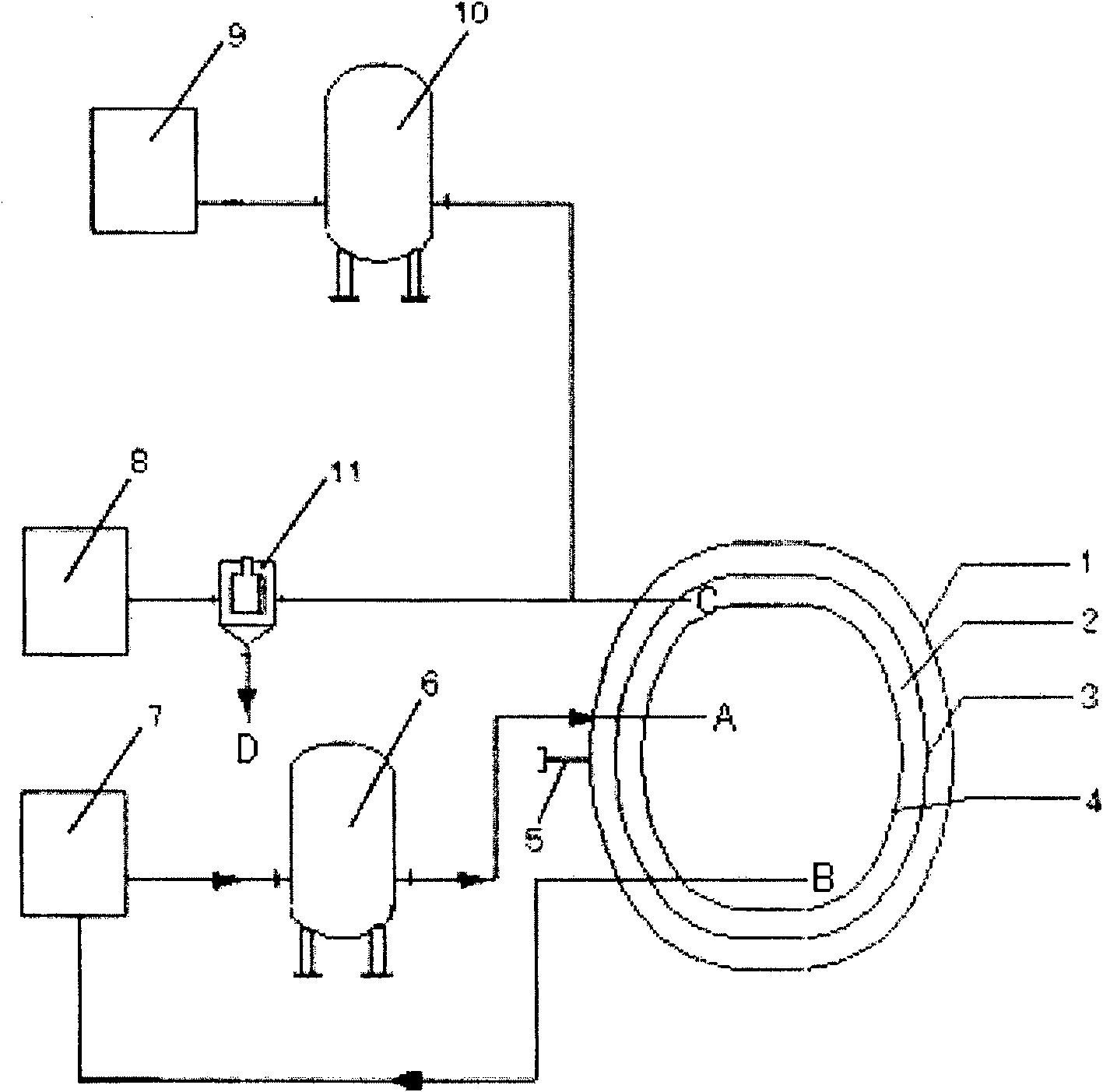

[0025] Such as figure 1 As shown in FIG. 2 , it is a schematic structural diagram of a vacuum pumping device according to a preferred embodiment of the present invention. The vacuum device according to the present invention is used to evacuate the interlayer between the outer cylinder and the inner cylinder of the multilayer heat insulation container, wherein the interlayer between the outer cylinder and the inner cylinder is filled with heat insulating material, and the high vacuum multilayer heat insulation container It can be used in cryogenic storage tanks, tank boxes or tank cars. The vacuum pumping device comprises: a first gas conveying device 7, which has an air outlet; a first gas heater 6, whose inlet is connected with the gas outlet of the first gas conveying device 7, and whose outlet is connected with the air inlet of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com