Conical parallel dual-screw extruding machine

A conical twin-screw and conical screw technology, applied in the field of conical twin-screw extruders, can solve the problems of small extrusion force, poor plasticizing performance, affecting product quality, etc., to maintain plasticizing performance and ensure plastic The effect of improving the quality and increasing the mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation

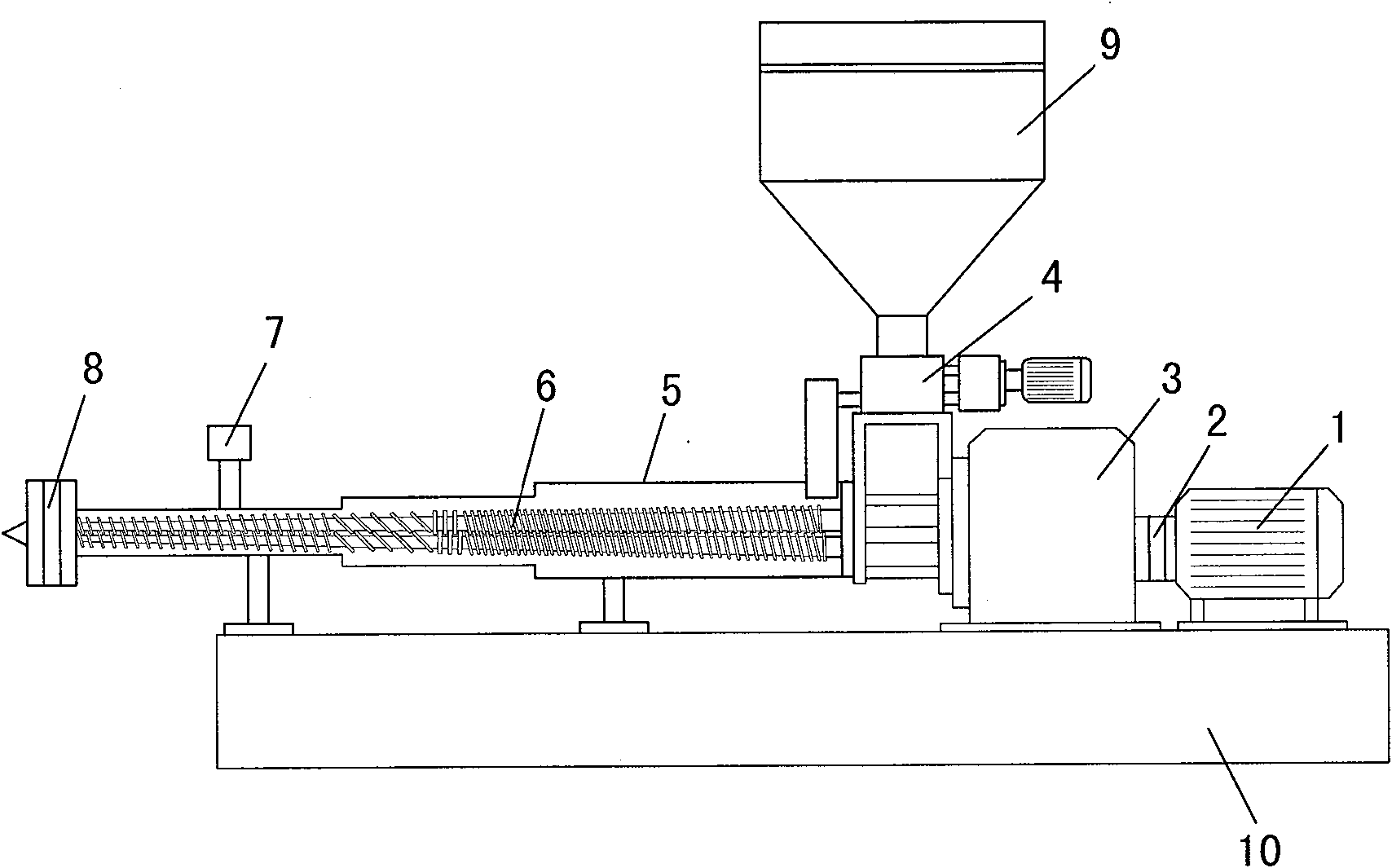

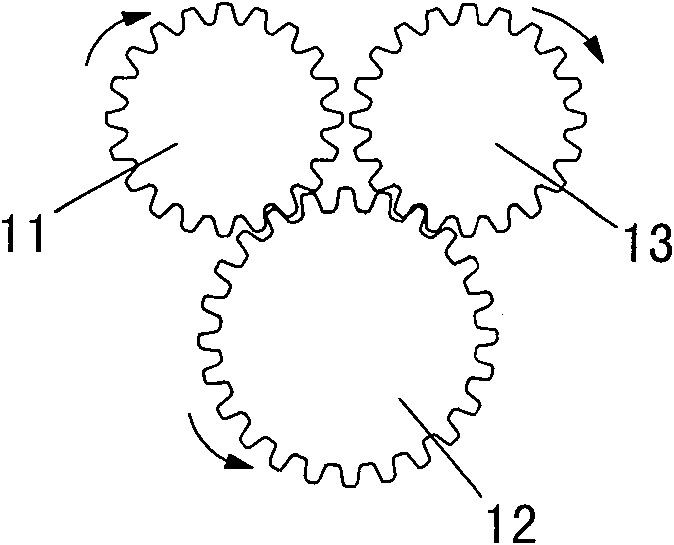

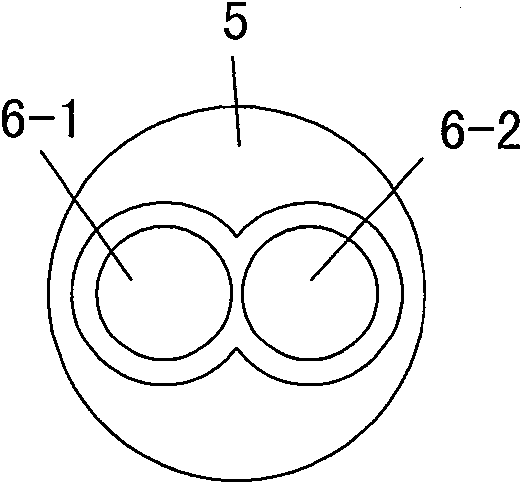

[0012] The structure of the present invention is attached figure 1 As shown, it consists of drive motor 1, coupling 2, deceleration distribution box 3, feeding system 4, barrel 5, conical twin screw 6, exhaust system 7, extrusion pelletizing system 8, hopper 9 and machine The structure of the present invention is that the screw 6 is composed of two conical screws 6-1 and 6-2, the conical screw 6-1 is the main screw, and the conical screw 6-2 is the auxiliary screw. Figure 4 shown, their position in the barrel 5 is shown in the appendix image 3 shown; in the reduction distribution box 3, three bevel gears are arranged, see appendix figure 2 As shown, the drive motor 1 is connected with the driving gear 11 through the coupling 2, the driving gear 11 is meshed with the intermediate gear 12, the intermediate gear 12 is meshed with the driven gear 13; the driving gear 11 is meshed with the main conical screw 6-1 Connected, the driven gear 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com