A preparation method of 6x82 matrix composite material for automobile control arm

A technology for automobile control arms and composite materials, which is applied in the field of preparation of high-performance aluminum-based composite materials for automobile control arms, can solve the problems of sacrificing plasticity and toughness, polluting alloys by by-products, reducing production efficiency, etc., so as to improve strength and modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] to N 2 Gas, K 2 ZrF 6 , K 2 TiF 6 and KBF 4 For reactant production (ZrB 2 +AlN+TiB 2 ) / 6X82Al composite material, wherein the nano-ZrB in the final composite material 2 Particles (0.15wt.%), nano-AlN whiskers (0.05~0.1wt.%) and submicron TiB 2 Particles (0.1wt.%), the rest is 6X82 alloy.

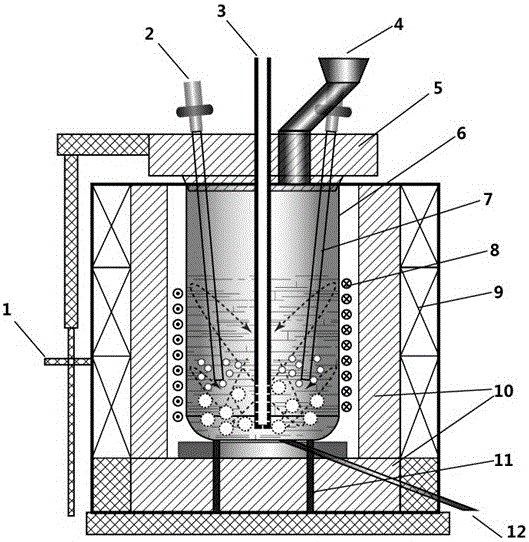

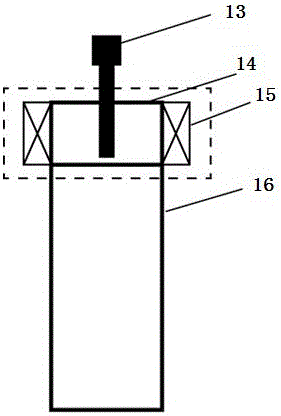

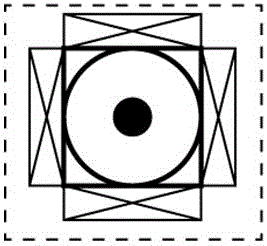

[0029] The 500kg 6X82 alloy melt that has been filtered by impurities, slag removed and degassed is introduced into the helical magnetic field-ultrasonic field combination device and the helical magnetic field is started (rotating magnetic field: current 50A, frequency 10Hz; traveling wave magnetic field: current 90A, frequency 15Hz ;Ultrasonic: power 1500W, frequency 20kHz, then industrial nitrogen, N 2 ≥99.8vol.%, the flow rate is 2L / min, through the high-purity graphite ventilation tube with air outlet at the bottom, it is passed into the melt, and the reactant powder K 2 ZrF 6 , K 2 TiF 6 and KBF 4 According to generate 3wt.% nanometer ZrB 2 Particles, 2wt.% submic...

Embodiment 2

[0032] Take NH 3 Gas, ZrO 2 、TiO 2 and B 2 o 3 For reactant production (ZrB 2 +AlN+Al 2 o 3 +TiB 2 ) / 6X82Al composite material, wherein the nano-ZrB in the final composite material 2 Particles 0.08wt.%, nano Al 2 o 3 0.248wt.% of particles, 0.05~0.1wt.% of nano AlN whiskers and submicron TiB 2 Particles 0.04wt.%, the rest is 6X82 alloy.

[0033] Enhancer reactant selection NH 3 , ZrO 2 、TiO 2 and B 2 o 3 , rotating magnetic field: current 50A, frequency 10Hz; traveling wave magnetic field: current 90A, frequency 15Hz; ultrasonic: power 1500W, frequency 20kHz; industrial ammonia, NH 3 ≥99.8vol.%, the flow rate is 3L / min, the reactant powder is ZrO 2 、TiO 2 and B 2 o 3 According to generate 2wt.% nanometer ZrB 2 Particles, 1wt.% submicron TiB 2 Particles, 2wt.% micron Al 3 When the amount of Ti particles is added, nano-Al is generated in the composite strengthener melt 2 o 3 The theoretical amount is 6.2wt.%, according to 4wt.% of the total amount of 6X8...

Embodiment 3

[0036] to N 2 Gas, K 2 ZrF, K 2 TiF 6 and B 2 o 3 For reactant production (ZrB 2 +AlN+Al 2 o 3 +TiB 2 ) / 6X82Al composite material, wherein the nano-ZrB in the final composite material 2 Particles 0.12wt.%, nano Al 2 o 3 0.183wt.% of particles, 0.05~0.1wt.% of nano AlN whiskers and submicron TiB 2 Particles 0.12wt.%, the rest is 6X82 alloy.

[0037] The gas reactant described in the preparation of reinforcement is N 2 , K 2 ZrF 6 、K 2 TiF 6 and B 2 o 3 , rotating magnetic field: current 50A, frequency 10Hz; traveling wave magnetic field: current 90A, frequency 15Hz; ultrasonic: power 1500W, frequency 20kHz, industrial N 2 The gas purity is not less than 99.8vol.%, and the flow rate is 1.5~3.5 L / min; the solid reactant is composed of K 2 ZrF 6 、K 2 TiF 6 and B 2 o 3 Composition, according to the formation of 4wt.% nano ZrB 2 Particles, 4wt.% submicron TiB 2 Particles, 5wt.% micron Al 3 When the amount of Ti particles is added, nano-Al is generated in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com