Drying device heat conducting oil compensator

A drying device and heat transfer oil technology, which is applied in drying, drying machines, heating devices, etc., can solve the problems of reducing the service life of heat transfer oil, safety accidents, and accelerating the carbonization speed of heat transfer oil, so as to slow down the carbonization speed and increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

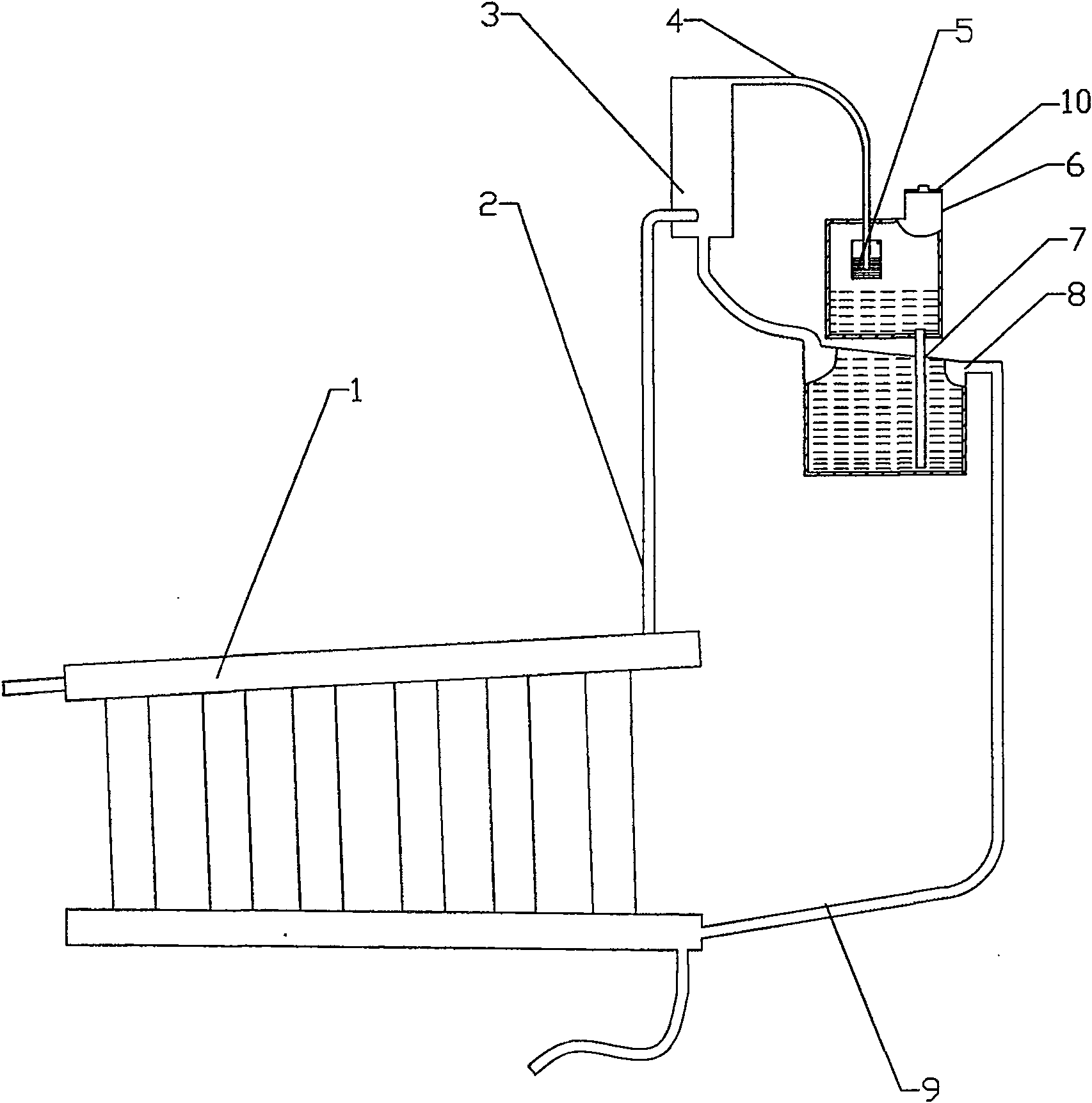

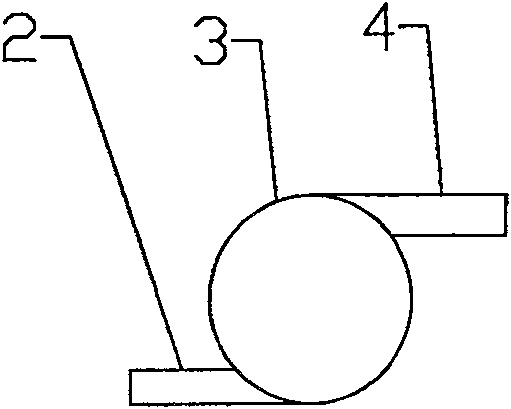

[0013] Examples such as figure 1 , 2 As shown, the heat transfer oil compensator of the drying device includes an oil-gas separator 3, and the exhaust pipe 2 of 1 on the cooling fin is connected to the oil-gas separator 3. The oil-gas separator 3 is cylindrical and placed vertically, and the exhaust pipe The gas in 2 enters the bottom of the oil-gas separator 3 tangentially, and the gas spirals up along the wall of the oil-gas separator to separate the oil and gas, and the oil flows into the oil storage chamber 8 through the pipeline under the oil-gas separator 3 , and the The top is connected to one end of the air pipe 4, and the other end of the air pipe 4 is inserted into the oil tank 5. The gas discharged from the exhaust pipe enters the oil tank 5 through the air pipe 4, and the oil tank 5 is equipped with cold oil for cooling. The setting of the oil tank makes the exhaust pipe The mouth is sealed by cold oil and does not directly contact the air, which slows down the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com