Valve core movement continuous adjustable electromagnetic valve

A proportional solenoid valve and solenoid coil technology, applied in the field of solenoid valves, can solve the problems of high cost, monotonous function, and bulky volume, and achieve the effects of low cost, compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

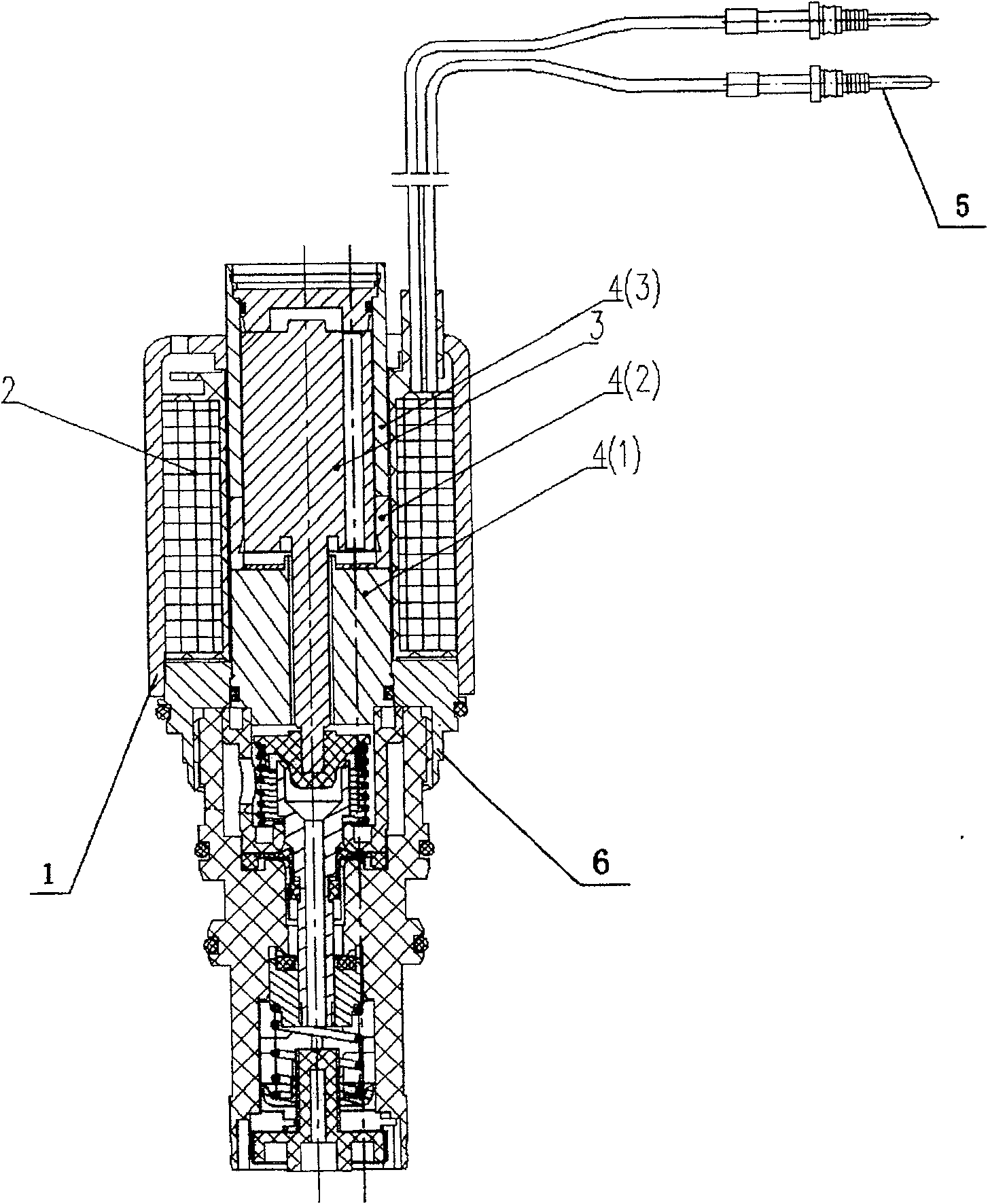

[0024] like figure 1 As shown, the electromagnetic valve with continuously adjustable spool movement of the present invention includes a valve casing 1, a coil 2 fixed in the valve casing 1, a wire 5 supplying power to the coil, and a static iron core 4 fixed on the casing 1 through a nut 6 And the moving iron core 3 placed in the static iron core 4. The valve core is riveted on the upper part of the moving iron core. In the case of no power supply, the spring presses the valve core and the moving iron core 3 to the bottom of the valve housing 1 together. When the coil 2 is energized, the magnetic force overcomes the spring force and lifts the moving iron core together with the valve core. Due to the special structure of the static iron core, under the control of the controller, the moving iron core and the valve core can be lifted to different positions. Degree.

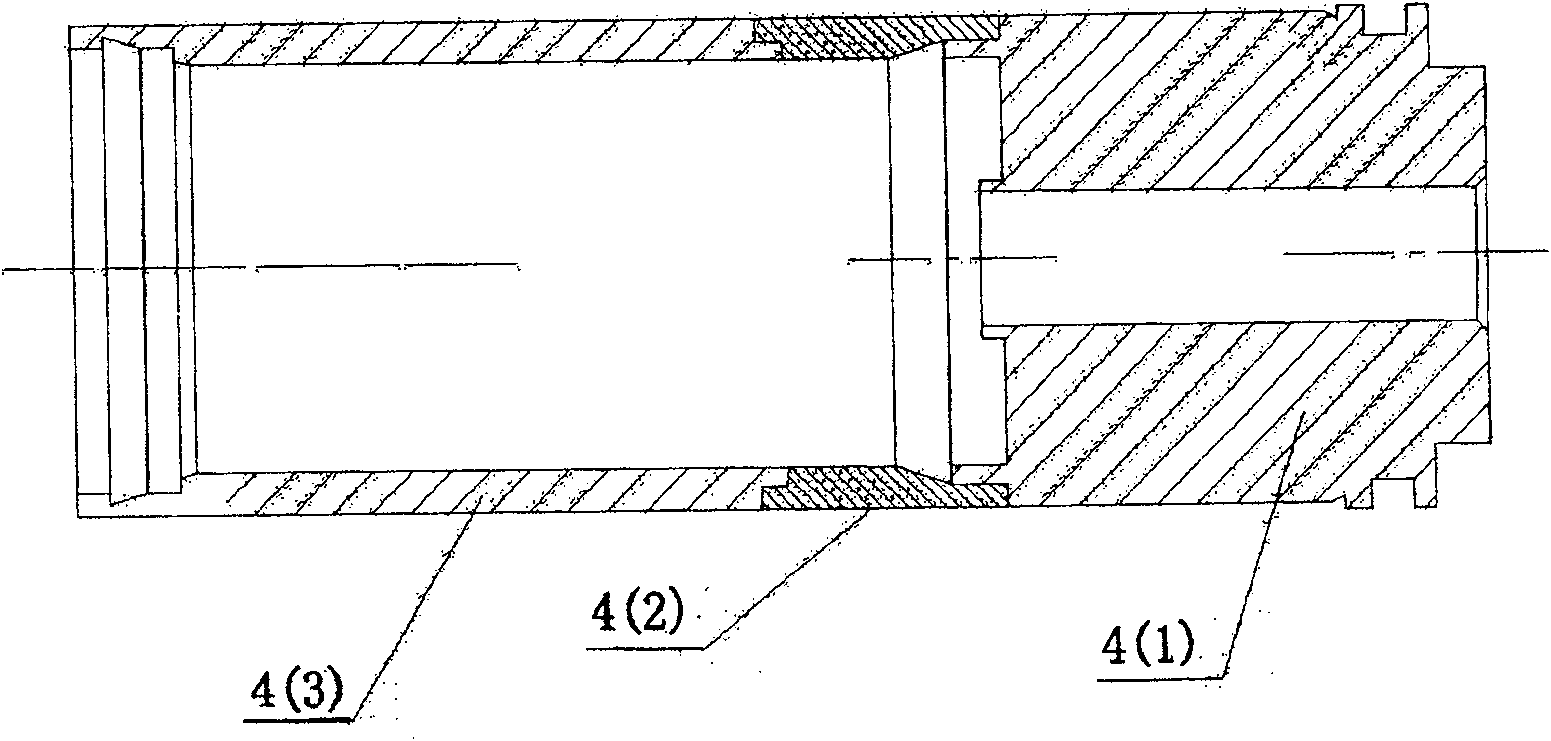

[0025] like figure 2 As shown, the static iron core of the electromagnetic valve with continuously adjustabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com