Ink resetting method based on JDF digitalization process

An ink and preset technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of uncommon data interfaces of printing machines, limited data export capabilities of pre-press systems, and unusable printing machines, etc., to achieve shortening Effect of printing preparation time, improvement of printing efficiency and printing quality, and reduction of printing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

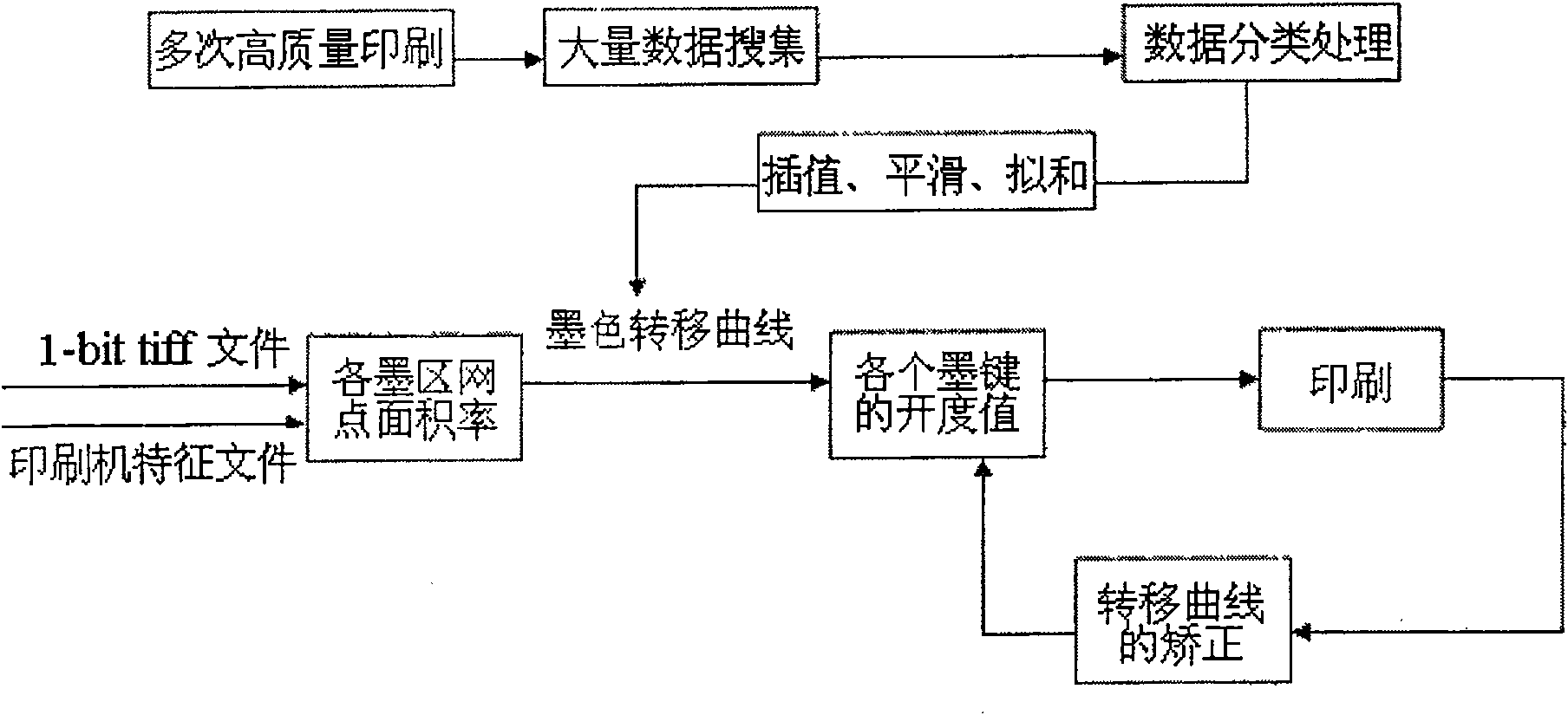

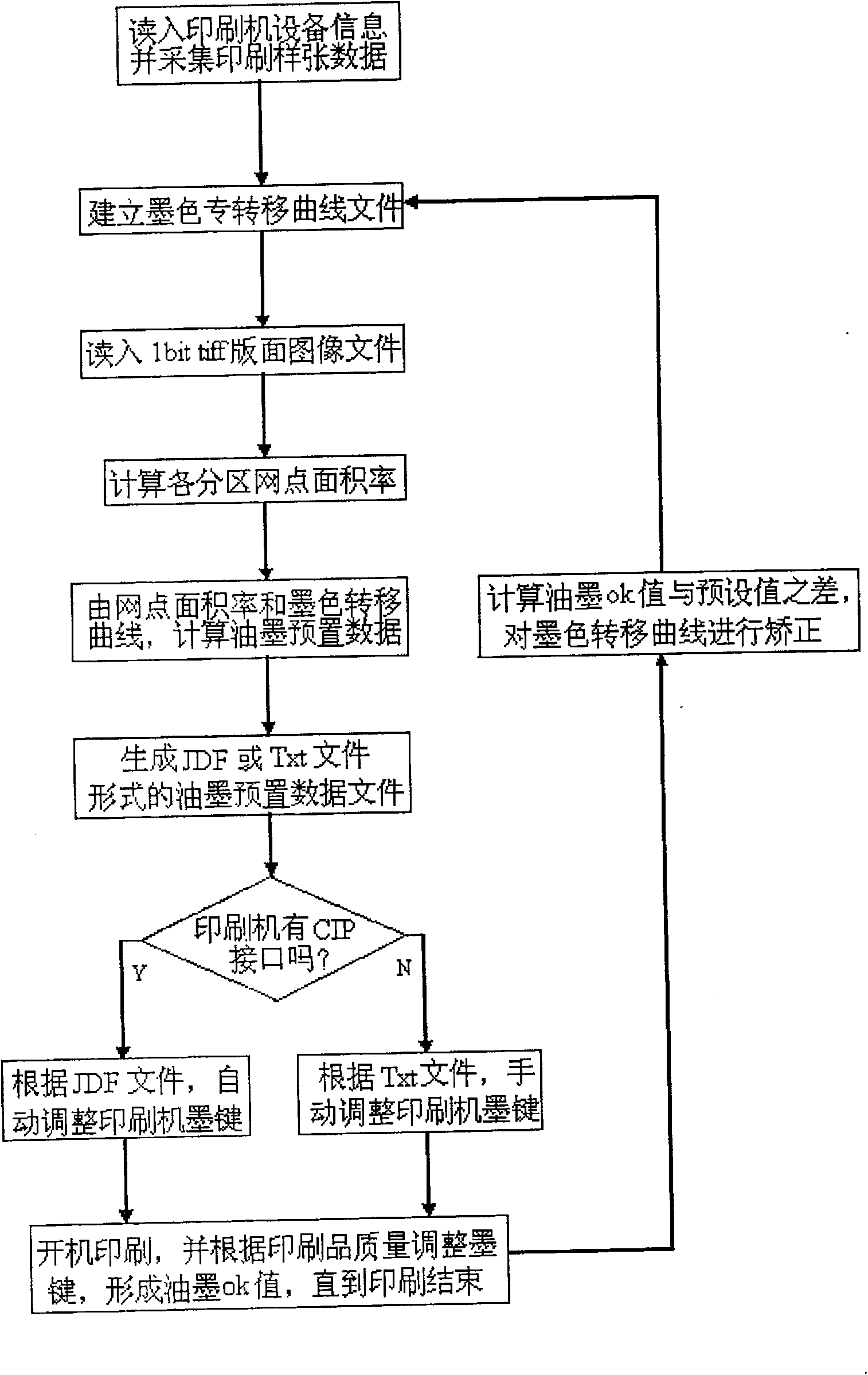

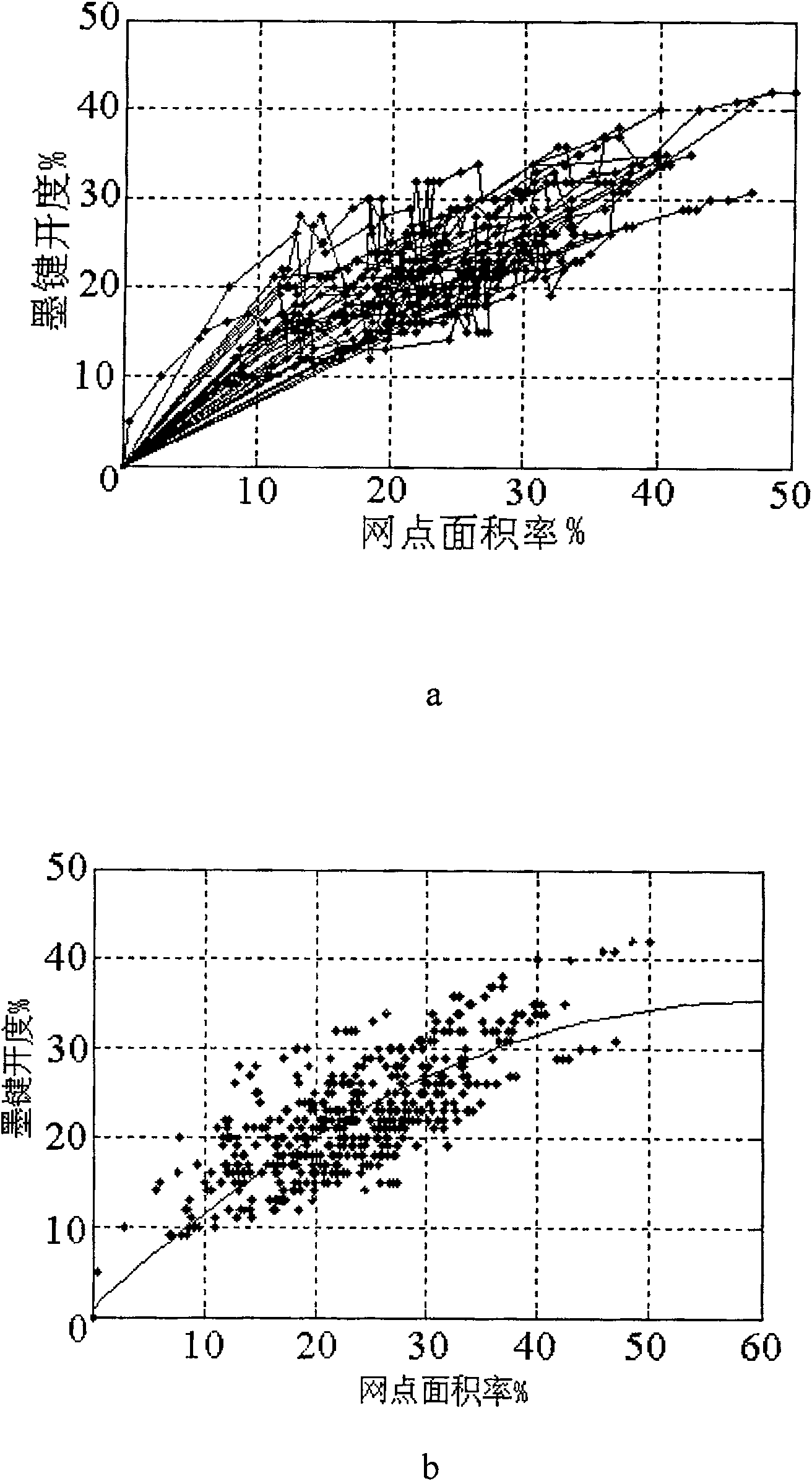

[0034] The flow process of the inventive method is as figure 1 shown. First, input the information of the printing machine equipment into the computer, generate the feature file of the printing machine, and save it in the form of an XML document; collect the information of the standard proofs printed by the printing machine for many times with high quality, and establish the ink color of the printing machine through data processing Transfer curve (also known as ink release curve); then, according to the layout information of the 1-bit tiff image file generated after imposition and the characteristic file of the printing machine, the dot area ratio corresponding to each ink area is extracted; according to the dot area ratio of each ink area Area ratio and ink color transfer curve, generate the preset data of each ink area, save it as a JDF fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com