Manufacturing technology of large rockwork rock

A kind of rockery and large-scale technology, which is applied in the field of imitation and replication of garden rock shapes, can solve the problems of difficult handling, insufficient strength, unstable foundation, etc., and achieve the effect of convenient construction and production, low price and strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

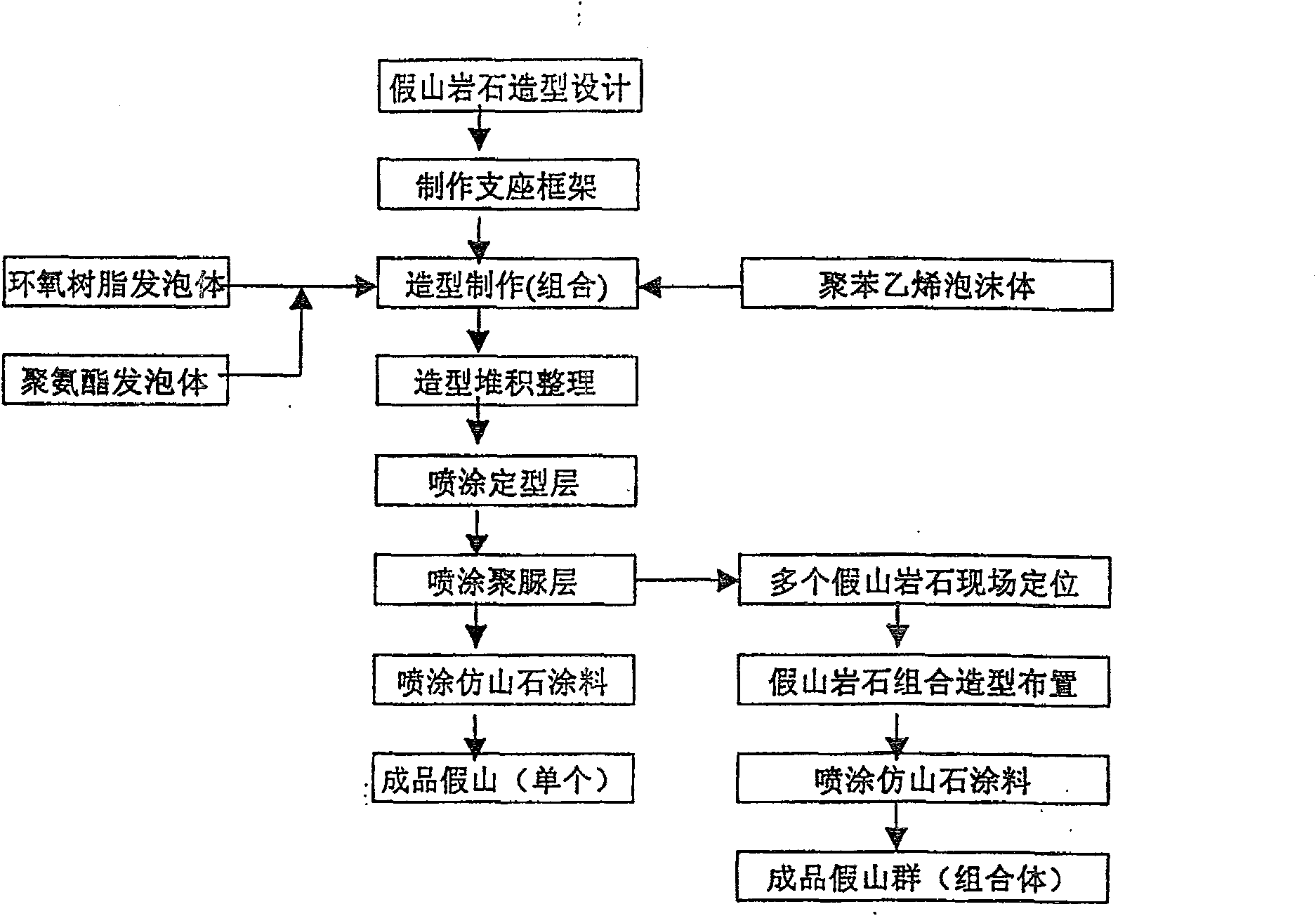

[0014] now attached figure 1 Further explain the present invention

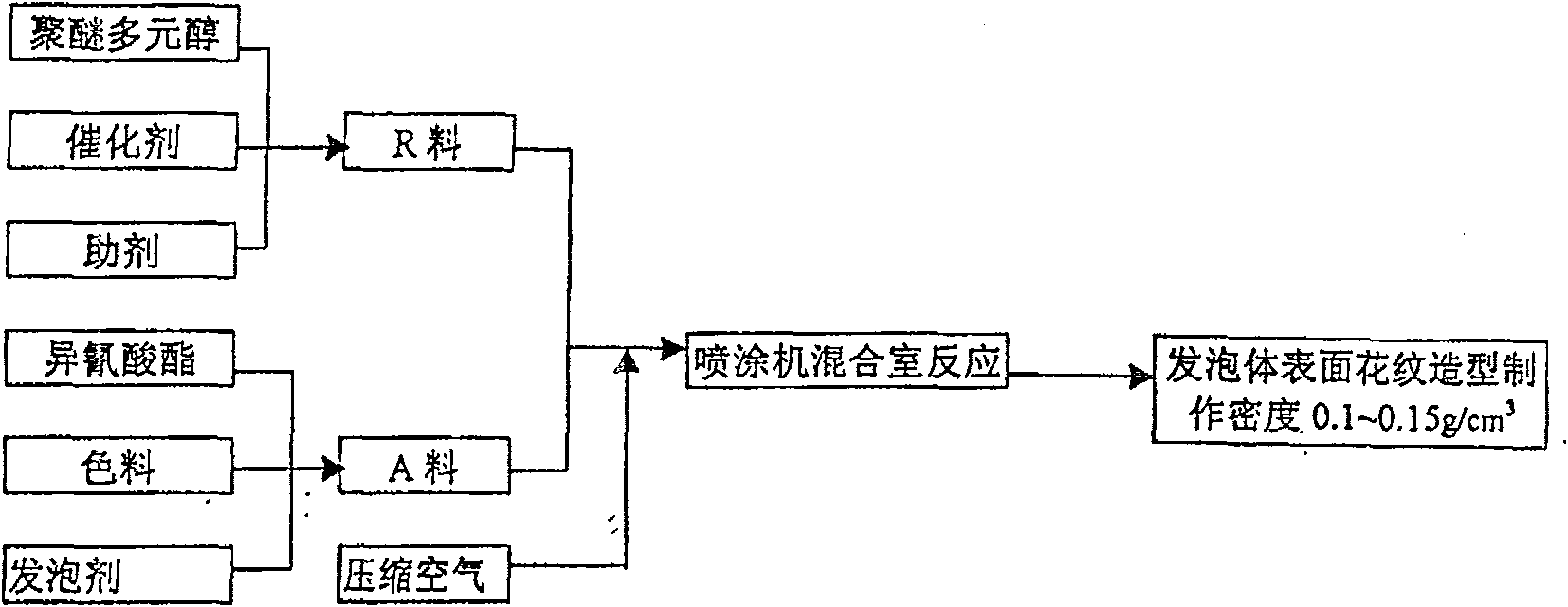

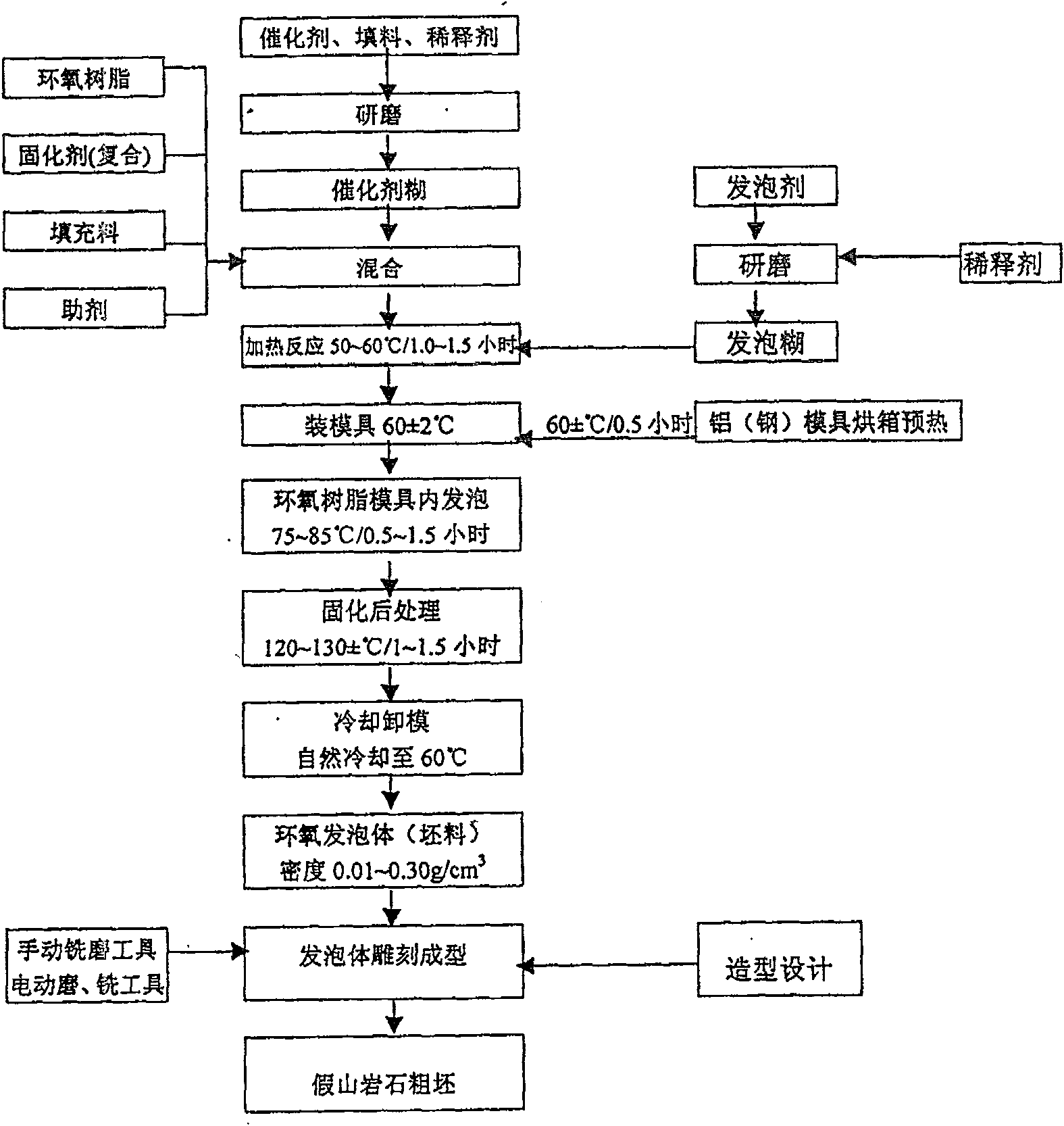

[0015] A manufacturing technique of large-scale rockery rocks. It is necessary to construct a base frame, make fillers and surface coverings. They use foam materials as fillers, pile them up in the underframe of the steel structure support, and carry out accumulation modeling and carving on them. Modeling, and then spray a shaping layer on the outer surface, then cover a layer of rigid polyurea coating in turn, and then cover a rock coating, and dry it to form a rockery landscape. Among them, the foam material is made of density of 0.1 ~ 0.3g / cm 3 Epoxy resin rigid foam material with a density of 0.05-0.30g / cm 3 Polyurethane casting rigid foam; density 0.012~0.030g / cm 3 High-quality polystyrene foam is piled up and mixed according to the needs of rockery modeling. The spray-coated shaping layer is a layer with a density of 0.1-0.15g / cm 3 rigid polyurethane foam. One layer of rigid polyurea coating is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com