Liquid control one-way valve for suspension moving top beam hydraulic chock

A technology of hydraulically controlled one-way valve and hydraulic support, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc., which can solve the problems of large liquid drainage resistance, poor liquid return, and long time consumption, so as to improve negative pressure resistance Ability, safe and reliable use, and shorten the effect of liquid return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

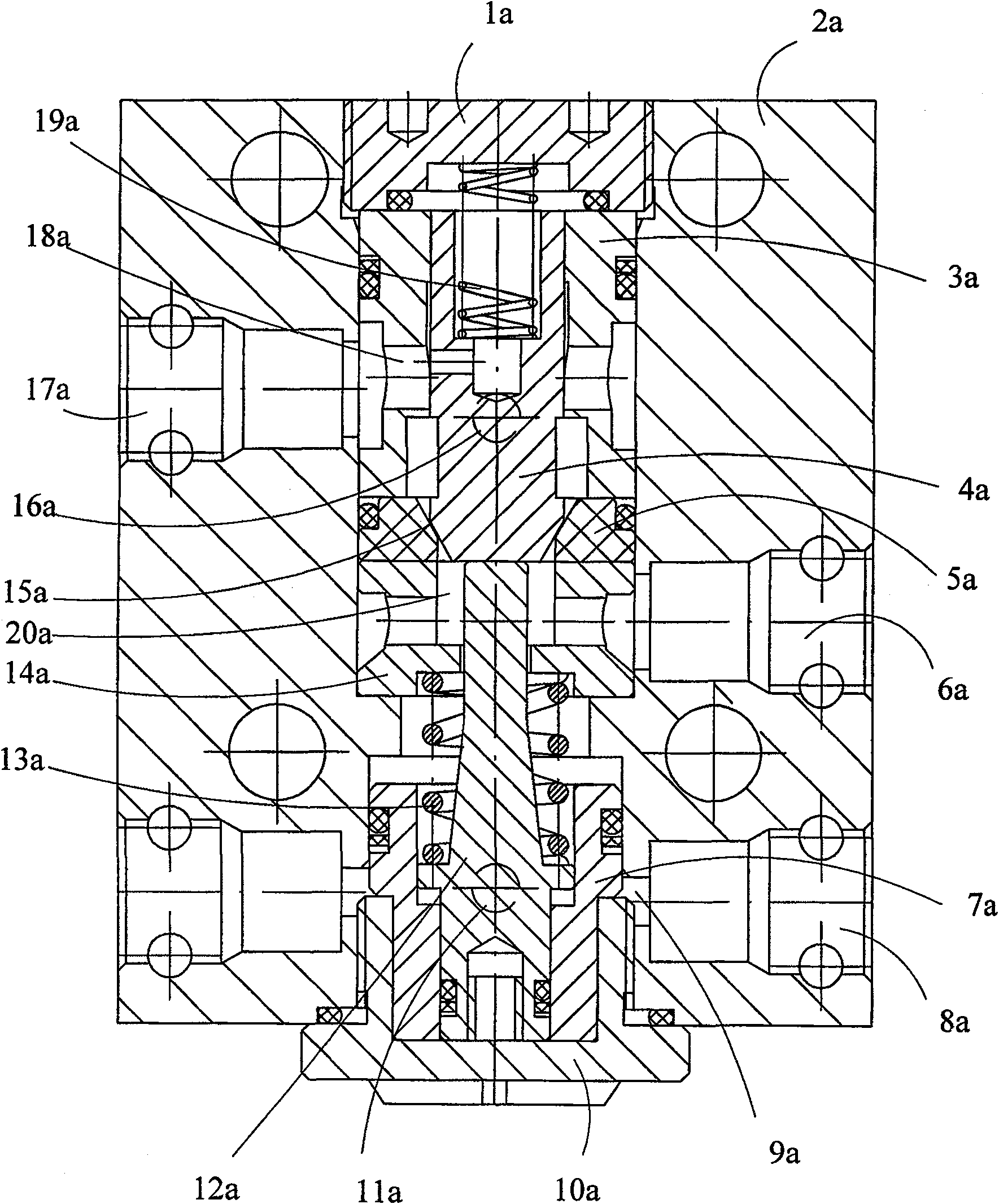

[0014] figure 1 The middle serial numbers represent: upper end cover 1a, valve body 2a, guide sleeve 3a, valve core 4a, valve seat 5a, support liquid injection hole 6a, ejector sleeve 7a, lifting cylinder liquid injection hole 8a, lower inner cavity 9a, lower end cover 10a, annular cavity radial through hole 11a, ejector rod 12a, return spring 13a, bushing 14a, sealing surface 15a, circular cavity radial through hole 16a, pressure gauge hole 17a, upper inner cavity 18a, spring 19a, middle inner The cavity 20a is connected to the screw hole 21a.

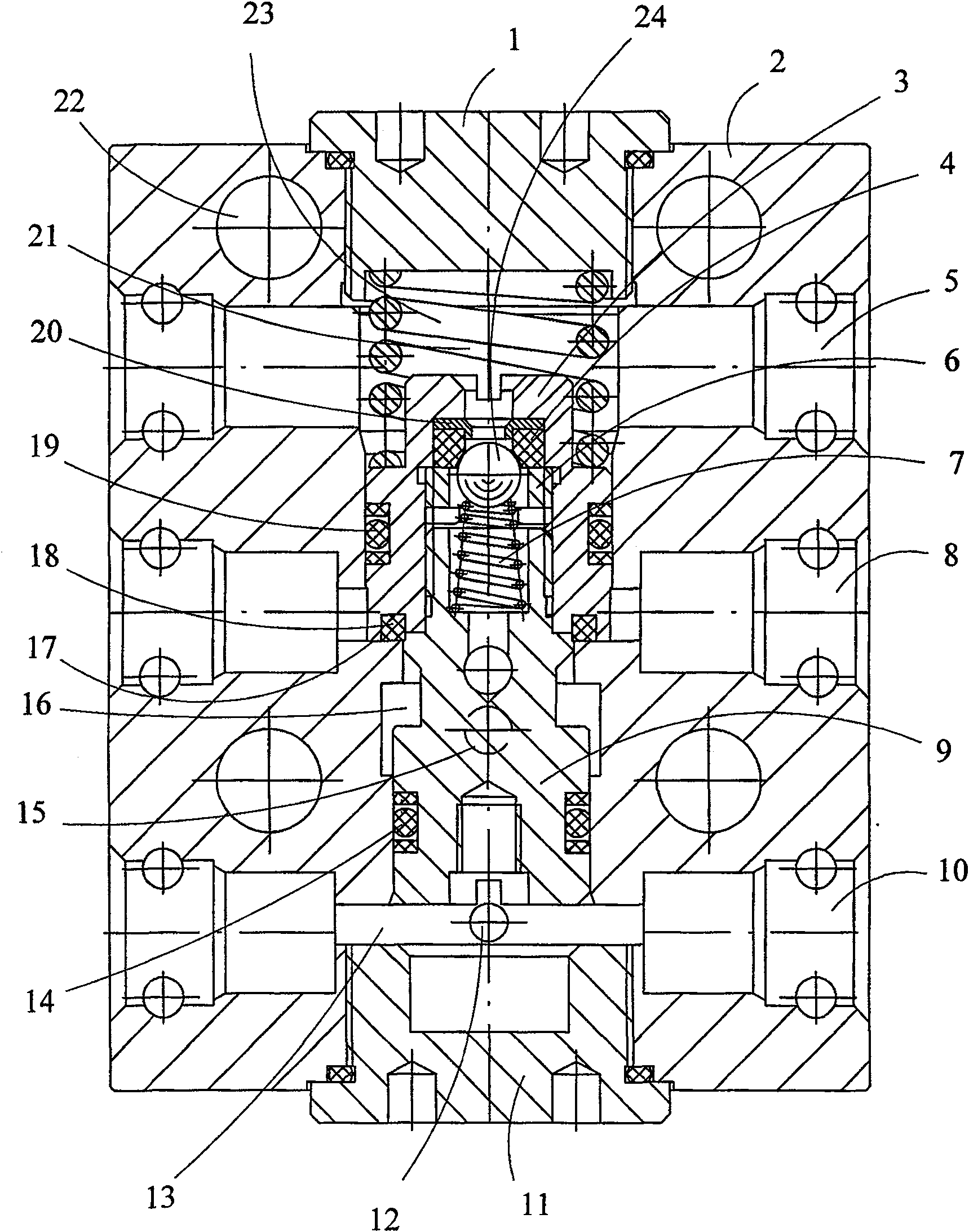

[0015] figure 2 The middle serial numbers represent: upper end cover 1, valve body 2, liquid injection valve body 3, valve seat 4, support liquid injection hole 5, compression screw sleeve 6, conical spring 7, liquid discharge hole 8, valve core 9, lift Cylinder liquid injection hole 10, lower end cover 11, annular cavity radial through hole 12, lower inner cavity 13, sealing assembly 14, circular cavity radial through hole 15, mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com