Silicon oxide film forming method and semiconductor device manufacturing method

一种氧化膜、半导体的技术,应用在半导体/固态器件制造、半导体器件、晶体管等方向,能够解决氧化速率的条件研究等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, the best mode of the present invention will be described with reference to the drawings.

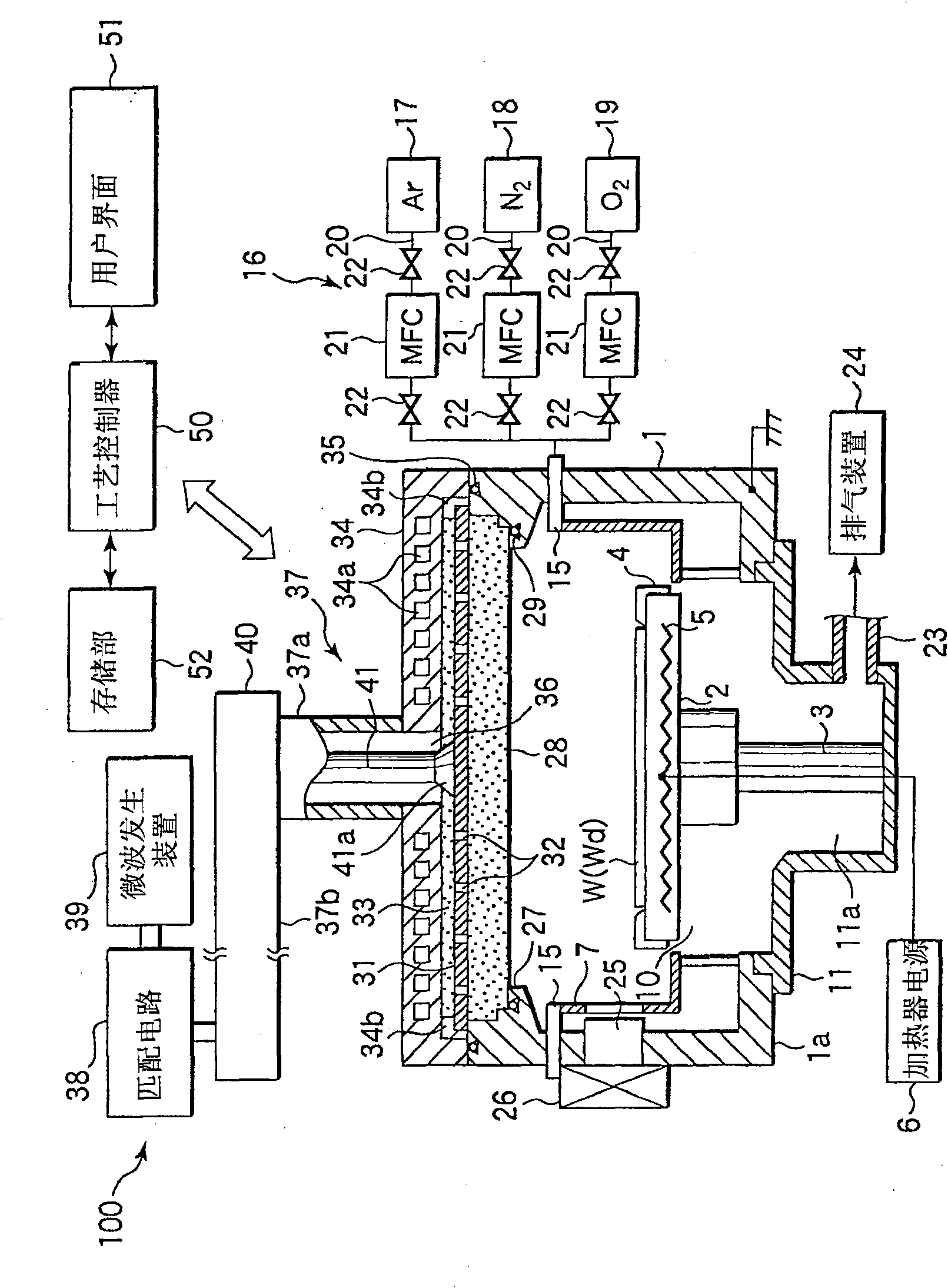

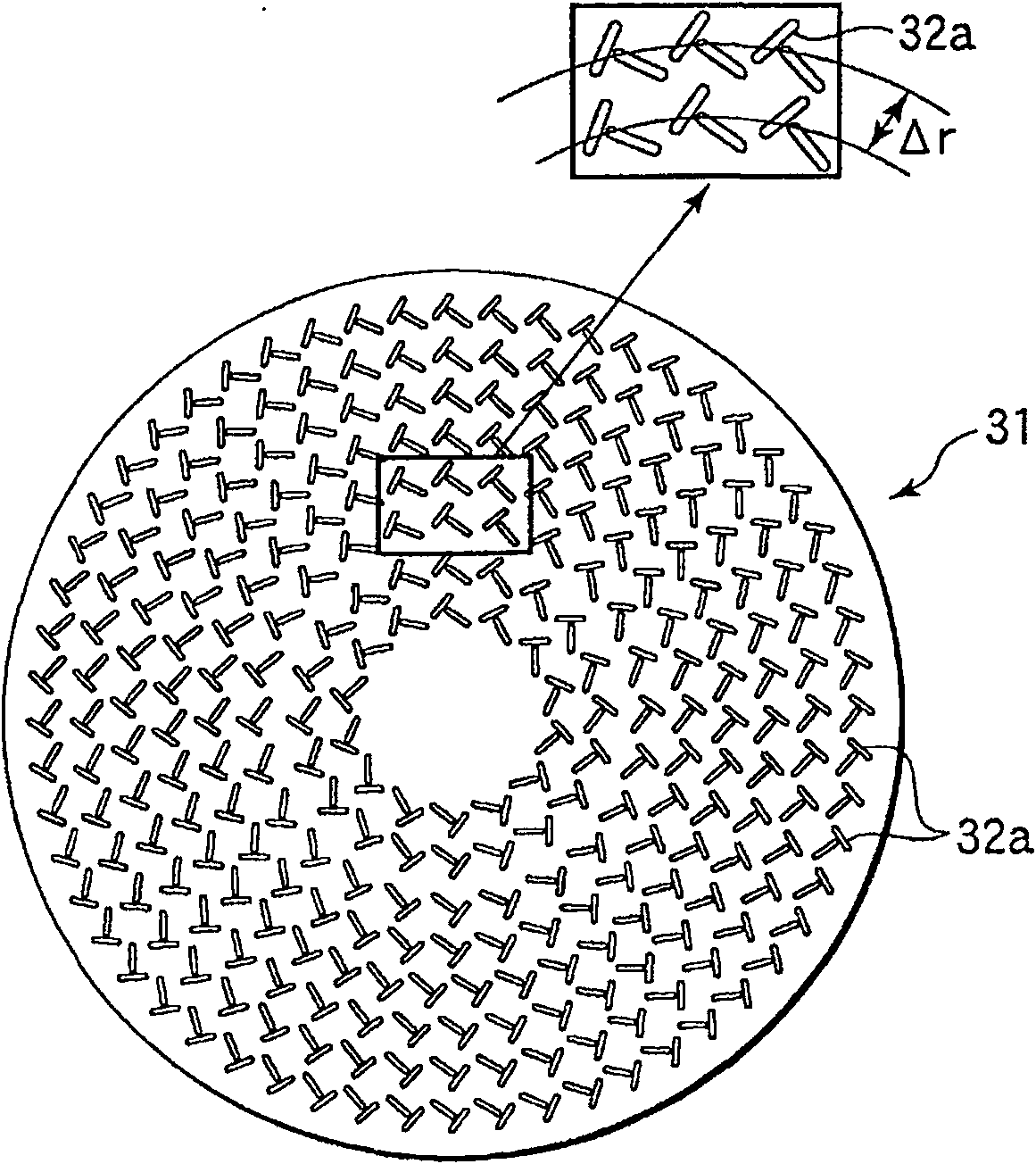

[0068] figure 1 It is a schematic cross-sectional view of an example of a plasma processing apparatus suitable for carrying out the method for forming an oxide film according to the present invention. This plasma processing apparatus utilizes the RLSA (Radial Line Slot Antenna; Radial Line Slot Antenna) plasma generation technology in which microwaves are introduced into the processing chamber through a planar antenna with a plurality of slots to generate plasma. microwave plasma.

[0069] The plasma processing device 100 can use plasma with a low electron temperature to perform plasma processing without damage to the bottom film at a low temperature below 600 degrees. At the same time, it can also achieve good plasma uniformity. Compared with the dense oxide film and the uniformity of the process, it is not inferior. Therefore, the plasma oxidation treatment appa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com