Solar photovoltaic car glass

A solar photovoltaic and automotive glass technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as unsatisfactory combination of solar cells and automobile body, installation and use affecting the appearance of the body, failure to achieve power generation/power consumption, etc. Achieve the effects of low light power generation performance, low cost, and good power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] 1. Solar photovoltaic automotive glass

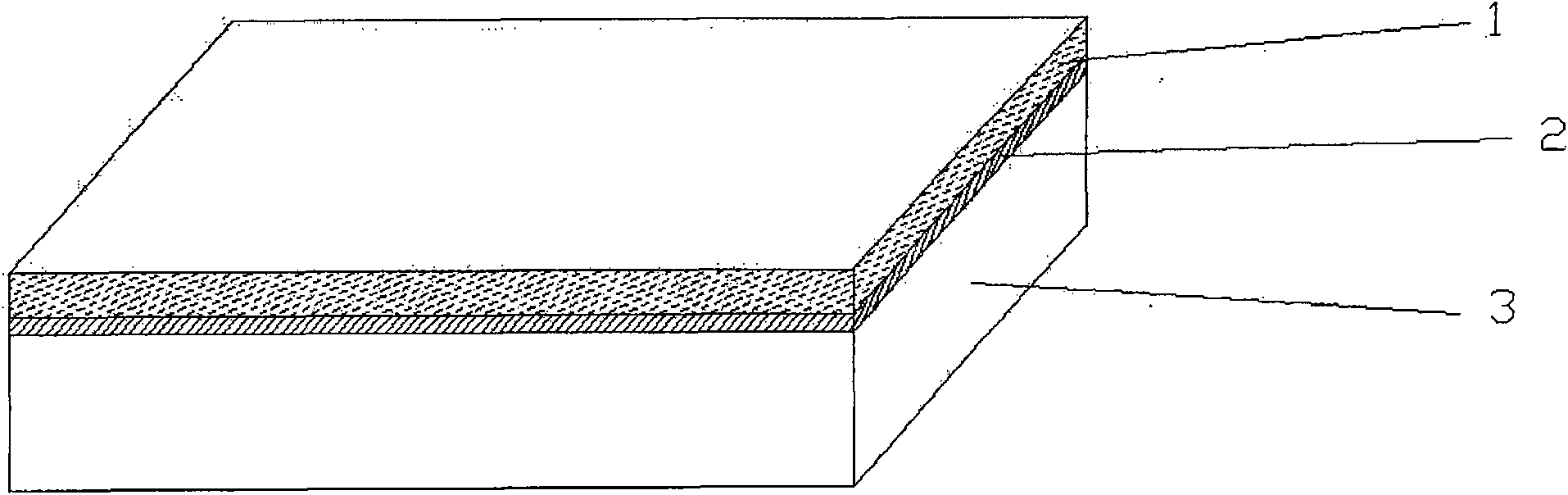

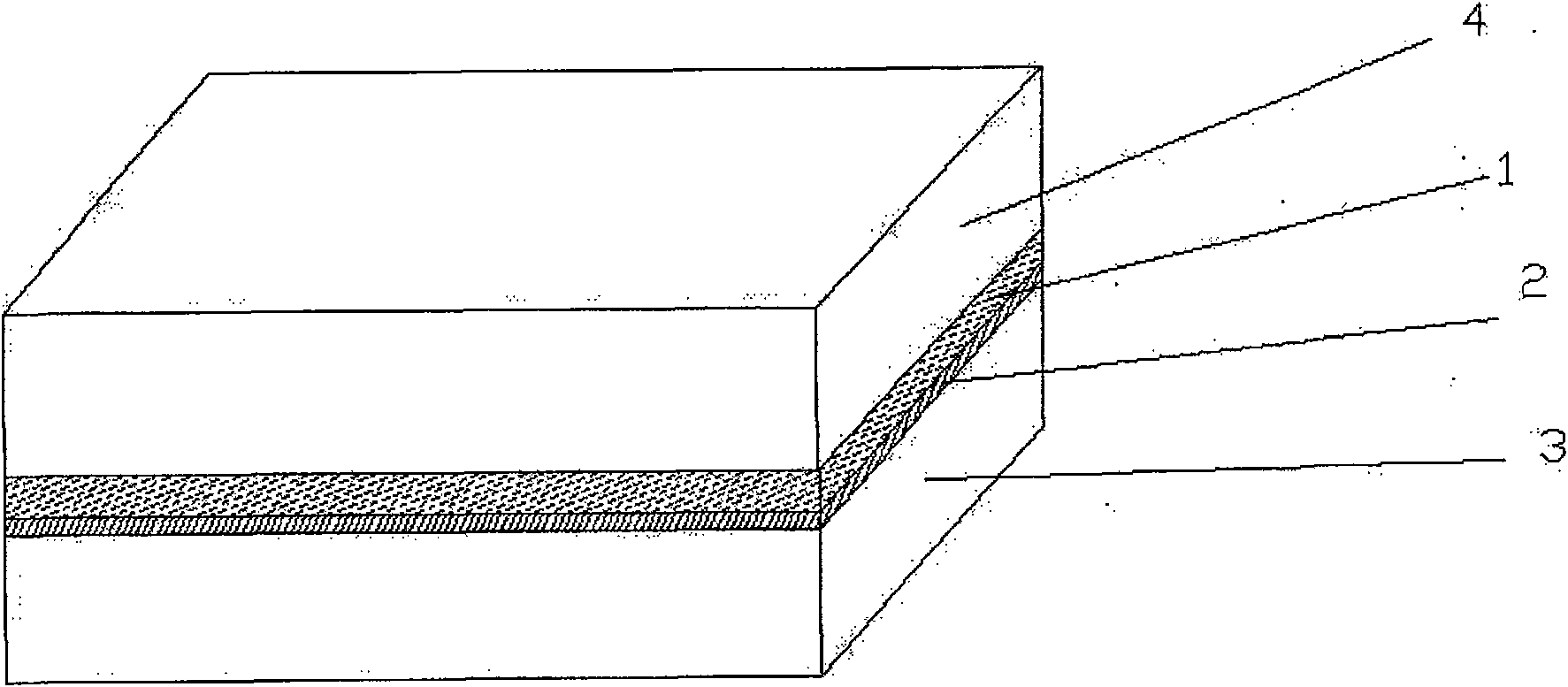

[0023] Such as figure 1 Shown, the solar photovoltaic automotive glass includes a single-layer tempered glass base 3 as a substrate, and a thin-film photovoltaic cell layer 2 on the single-layer tempered glass base 3. The opposite side of the contact is covered with a transparent resin material layer 1. The thin film photovoltaic cell layer 2 is an amorphous silicon thin film photovoltaic cell. Two leads are arranged on the electrode of the amorphous silicon thin film photovoltaic cell. The lead wires of the electrodes are connected to the electrical loads of the automobile (various electrical appliances, interior lighting, storage batteries, etc.), and the charge and discharge control box has multi-mode voltage outputs (such as: 3.5V, 5V, 12V, etc.) and multi-type External interface type to meet the power supply needs of automotive electrical appliances, and can charge various interfaces of automotive electrical loads, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com