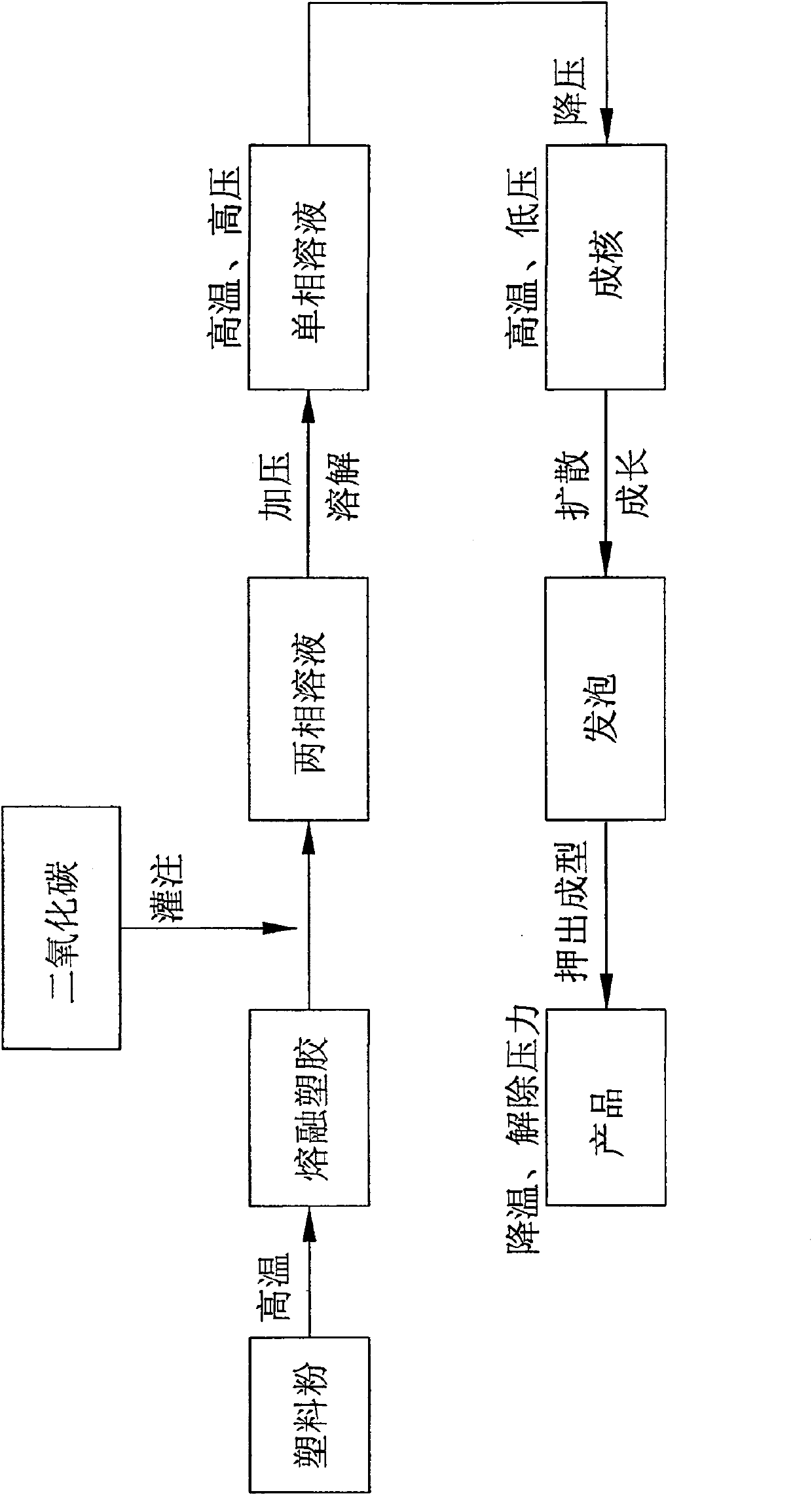

Solid CO2 supercritical foaming process

A technology for solid carbon dioxide and carbon dioxide, which is applied in the field of solid carbon dioxide supercritical foaming process, can solve the problems of difficult control of carbon dioxide gas flow, difficult product quality control, and high factory operating costs, so as to improve the diffusion rate and dissolution efficiency and reduce equipment costs. , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

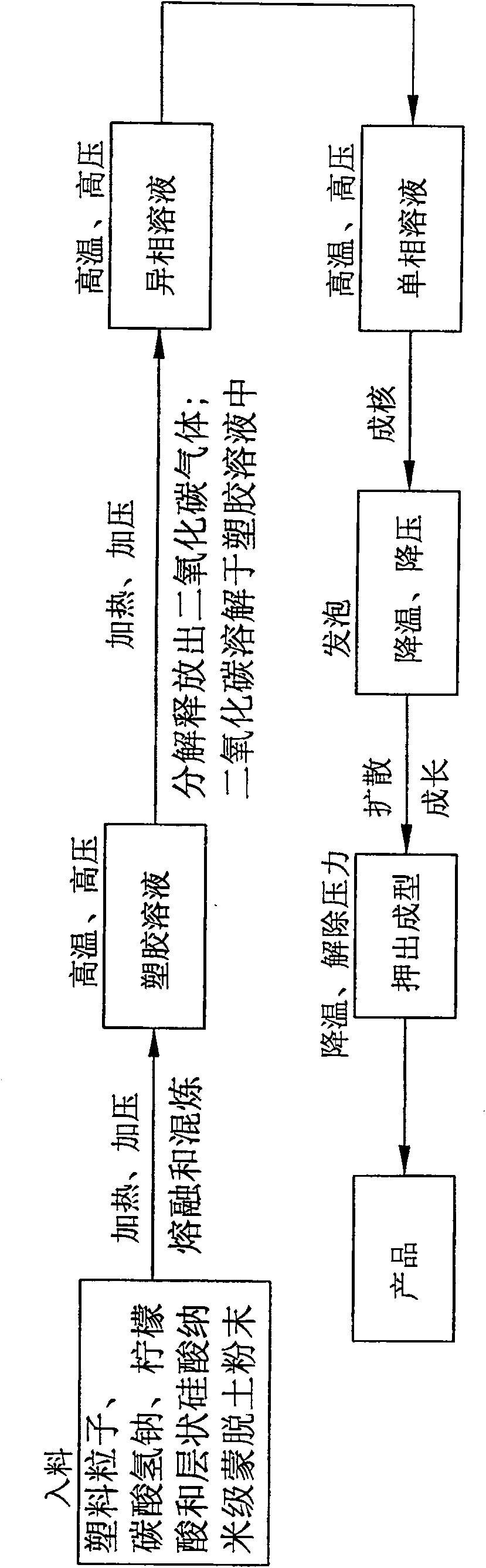

[0029] In order to further disclose the present invention, the following in conjunction with the attached figure 2 and specific examples.

[0030] It includes the following steps:

[0031] A. Mix sodium bicarbonate, citric acid and layered silicic acid nano-sized montmorillonite powder into the plastic particles and stir evenly. Wherein, the plastic particles are thermoplastics, sodium bicarbonate is industrial sodium bicarbonate, and the weight ratio of sodium bicarbonate to plastic particles is 100:0.5-3; citric acid is a nucleating agent, which is used to induce the formation of air bubbles, while , citric acid also has the effect of dispersing air bubbles and dispersing micropores, making it produce more and smaller air bubble nuclei in the foaming process, and the weight ratio of citric acid and plastic particles is 100: 0.25~1.5; in this embodiment , said plastic particles are also added with industrial layered silicic acid nano-montmorillonite, the weight ratio of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com