Polyanion cellulose preparation method

A polyanion and cellulose technology, applied in the field of fine chemicals, can solve the problems of incomplete alkalization and etherification, unsatisfactory product performance indicators, low production efficiency, etc., and achieve the effects of superior effect, superior water retention performance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

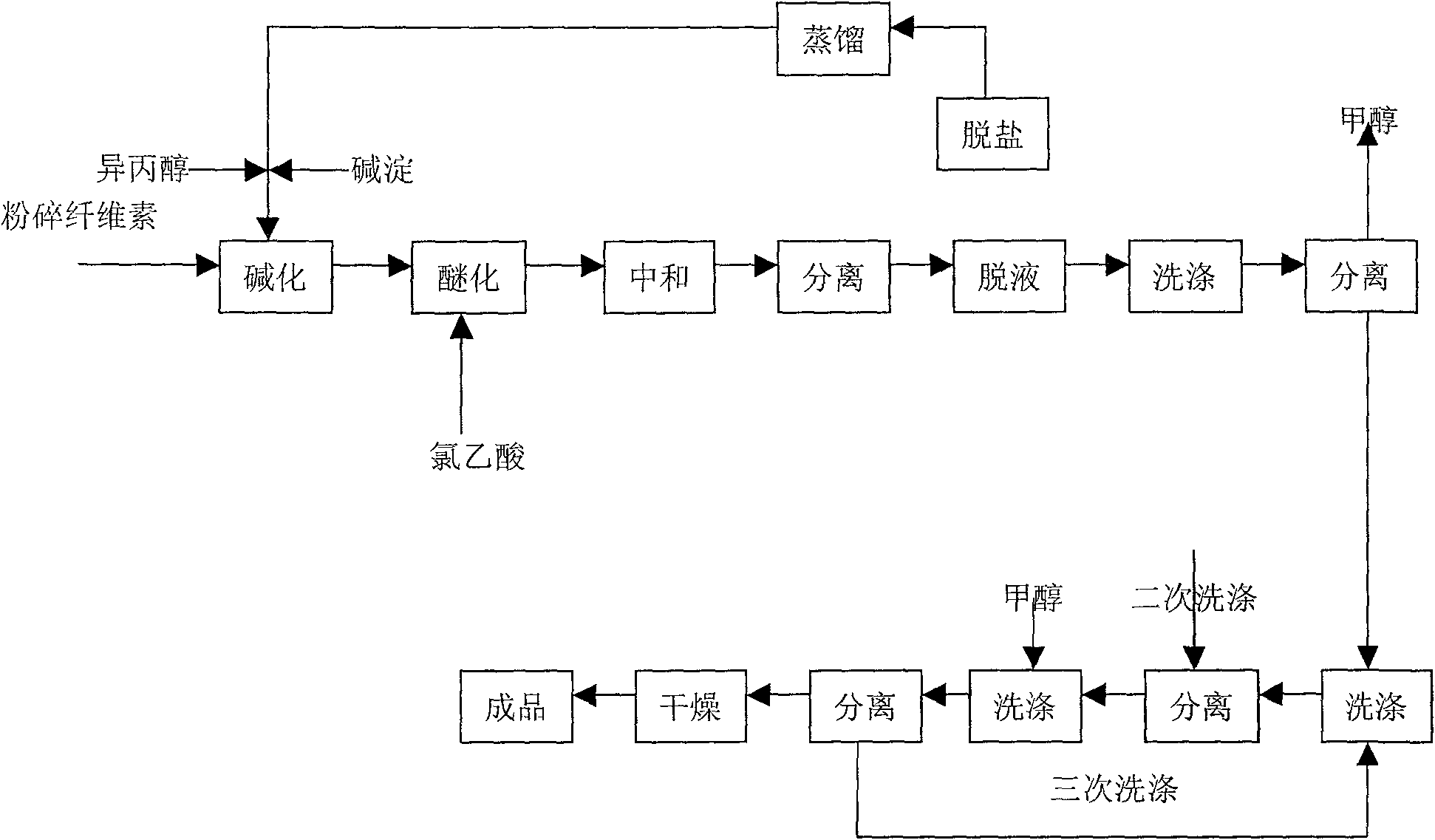

Method used

Image

Examples

Embodiment 1

[0046] Mix the following components to prepare a ternary composite solvent for the preparation of polyanionic cellulose: A, isopropanol (concentration ≥ 98%), 87%; B, ethanol (concentration ≥ 95%), 10%; C, Soft water (hardness≤3), 3%.

Embodiment 2

[0048] The following components are mixed to prepare a ternary composite solvent for preparing polyanionic cellulose: A, isopropanol, 71%; B, ethanol, 20%; C, soft water, 9%.

Embodiment 3

[0050] The following components are mixed to prepare a ternary composite solvent for preparing polyanionic cellulose: A, isopropanol, 78%; B, ethanol, 14%; C, soft water, 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com