Manufacturing method of hot dip galvanizing steel plate

A technology of hot-dip galvanized steel sheet and manufacturing method, applied in hot-dip galvanizing process, coating, metal material coating process, etc. The effect of reduced peeling and other phenomena, low cost, and optimized grain orientation of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Preparation of hot-dip galvanized steel sheet experimental examples 1-10 and comparative examples 11-20

[0019] The thickness is 0.8mm, the composition is C: 0.03~0.07%, Mn: 0.01~0.03%, Si: 0.19~0.30%, P: 0.006~0.019%, S: 0.009~0.020%, Al: 0.02~0.07%, The rest of the DX51D cold-rolled steel sheets containing Fe and impurities are pickled and annealed, and then hot-dip galvanized under the hot-dip galvanizing process conditions listed in Table 1. The temperature of the galvanizing bath in the zinc pot is 450 ° C, and the Fe content 2 Left and right, the surface of the zinc layer passes through SiO 2 passivation treatment. The following methods are used to evaluate the coating adhesion properties such as the grain orientation of the coating and the anti-shedding performance, scratch resistance, and wear resistance of the coating.

[0020] Table 1 Hot-dip galvanizing process conditions

[0021]

Embodiment 2

[0022] Embodiment 2 Performance measurement of hot-dip galvanized steel sheet experimental examples 1-10 and comparative examples 11-20

[0023] (1) Coating grain orientation

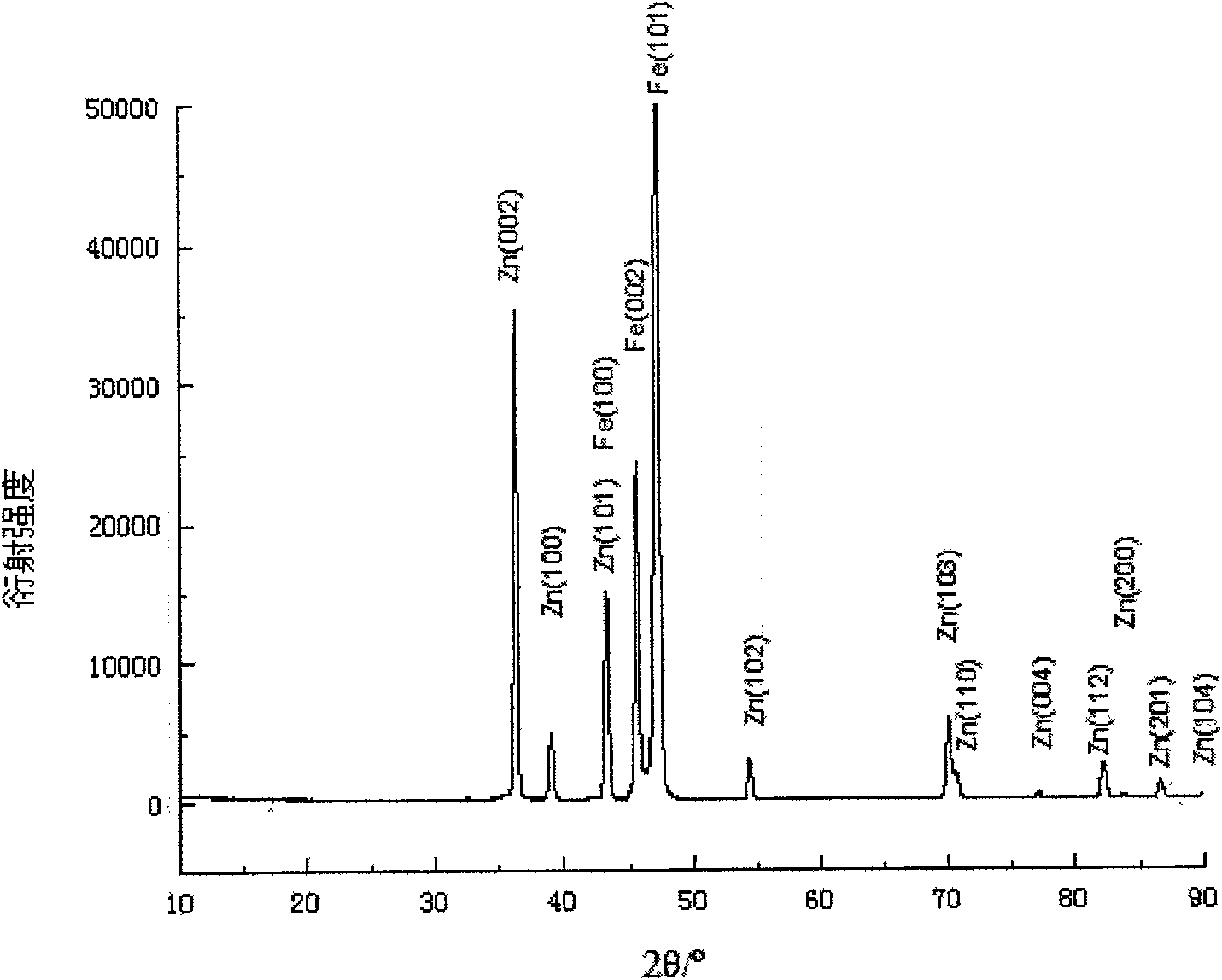

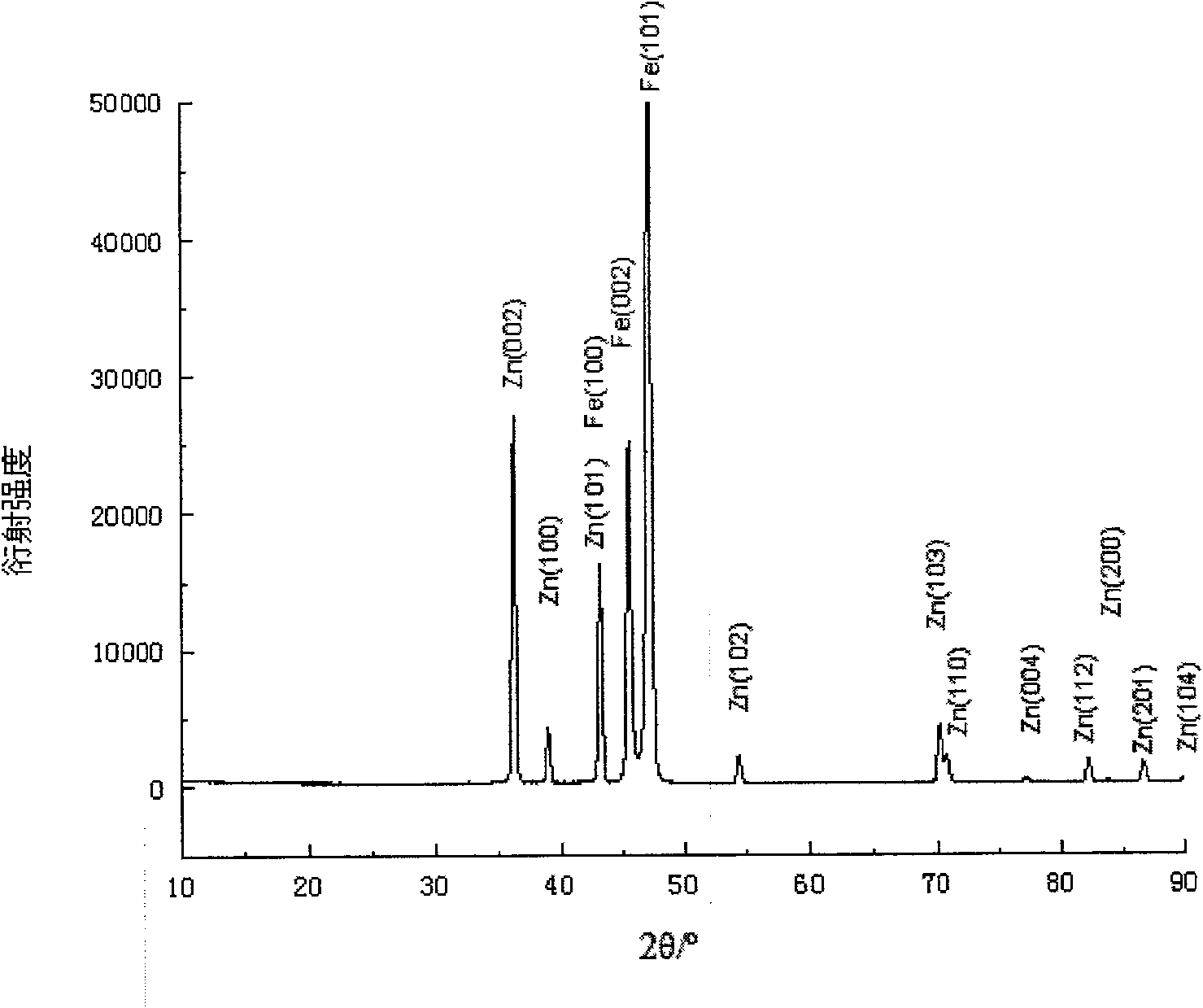

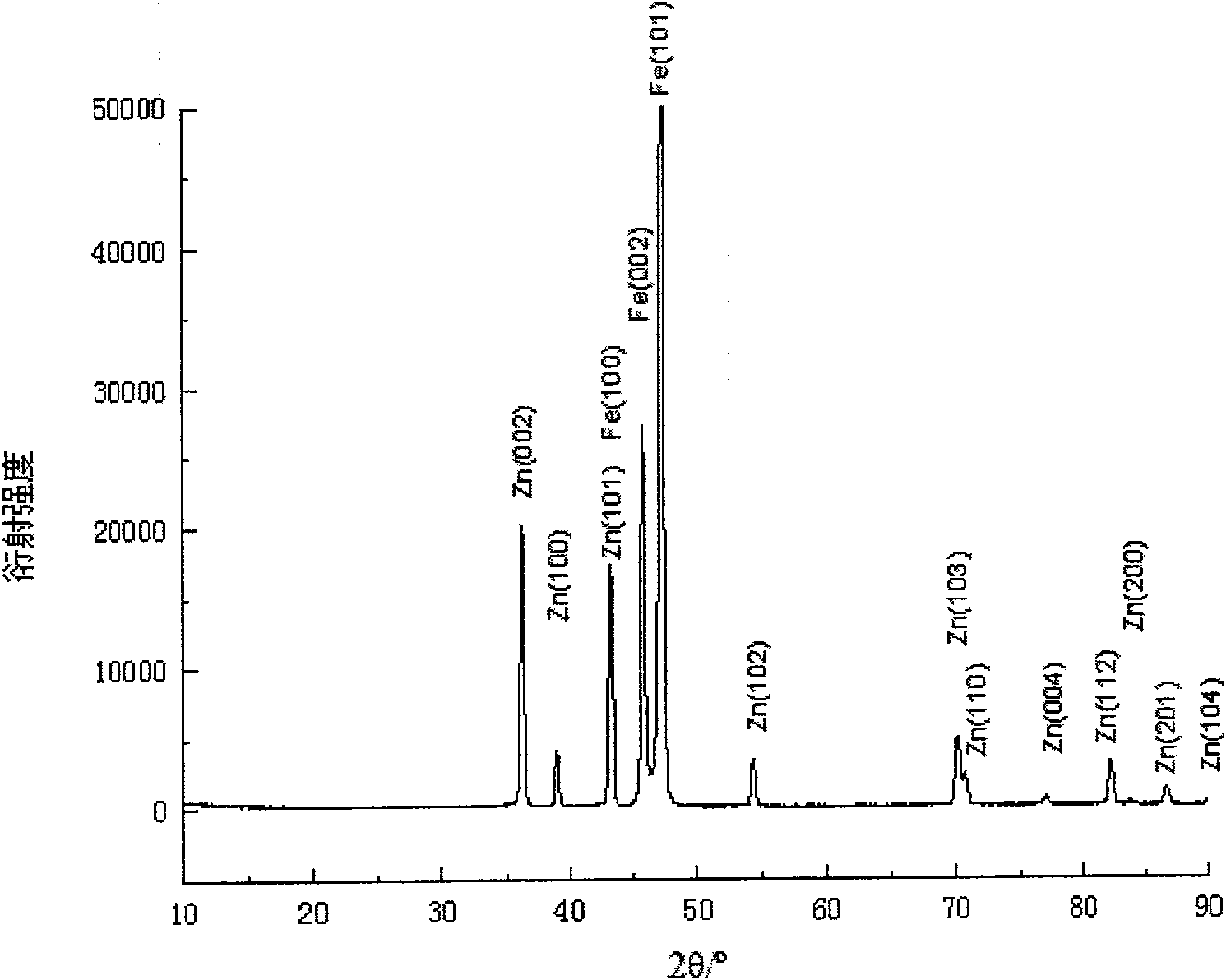

[0024] The surface of the coating was not treated in any way, and the small-angle diffraction (grazing angle 5°) of the coating was respectively carried out on the X-ray diffractometer (XRD) to measure the diffraction peak intensity of the coating. Typical diffraction patterns of experimental examples 1 and 6 and comparative examples 11 and 15 coating surface at 5 ° grazing angle are shown in Fig. 1. It can be seen that the intensity of the strongest diffraction peak Zn(002) of Zn in the coatings of Experimental Examples 1 and 6 is much higher than that of Comparative Examples 11 and 15, and the strong peak of Zn is transferred from Zn(101) to Zn(002). Table 2 has listed the diffraction intensity of each sample Zn(002) peak, and it can be seen that compared with the comparative example that the cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com