Large power tube lead-free sealed glass powder and its preparation method

A technology for sealing glass and glass powder, which is applied in the chemical industry, can solve problems affecting the fluidity and airtightness of glass sealing, large thermal expansion coefficient of glass, unfavorable industrial application, etc., and achieve excellent chemical stability, low softening temperature, Easy to adjust the effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

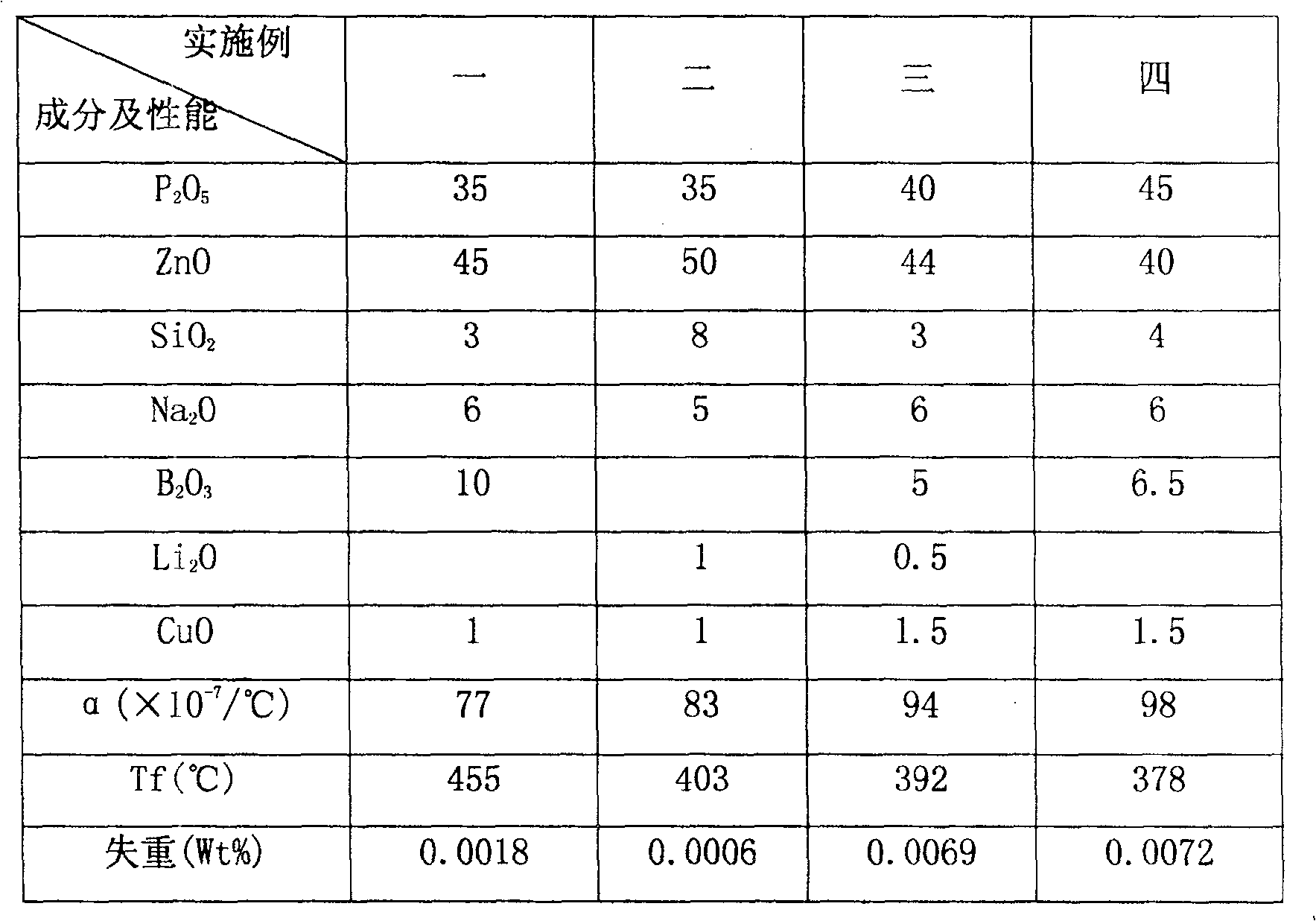

[0029] Table 1 (mol%)

[0030]

[0031] Weigh each component according to the molar percentage of the raw materials in Table 1, then fully mix the raw materials, keep the mixture at 200 ° C for 1.5 hours, and then melt it at the melting temperature of 1050 ° C ~ 1250 ° C, keep it warm 1 to 2 hours.

[0032] The chemical stability of the glass was measured after constant temperature in deionized water at 90°C for 9 hours.

[0033] In Table 1, P 2 o 5 , ZnO, SiO 2 and Na2 Four kinds of oxides of O are used as essential components. By adding different other components and adjusting the ratio relationship between the components, the expansion coefficient can be obtained from 65 to 140×10 -7 / °C, sealing glass with a sealing temperature of 420-570°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com