Leadless low-melting glass powder for seal with metal or alloy and preparation method thereof

A low-melting-point glass and glass powder technology, which is applied in the field of lead-free low-melting-point glass powder and its preparation, can solve the problems of poor chemical stability and electrical performance, unfavorable industrial application, and unusable sealing, etc., and achieve wide market development Prospect, excellent chemical stability, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

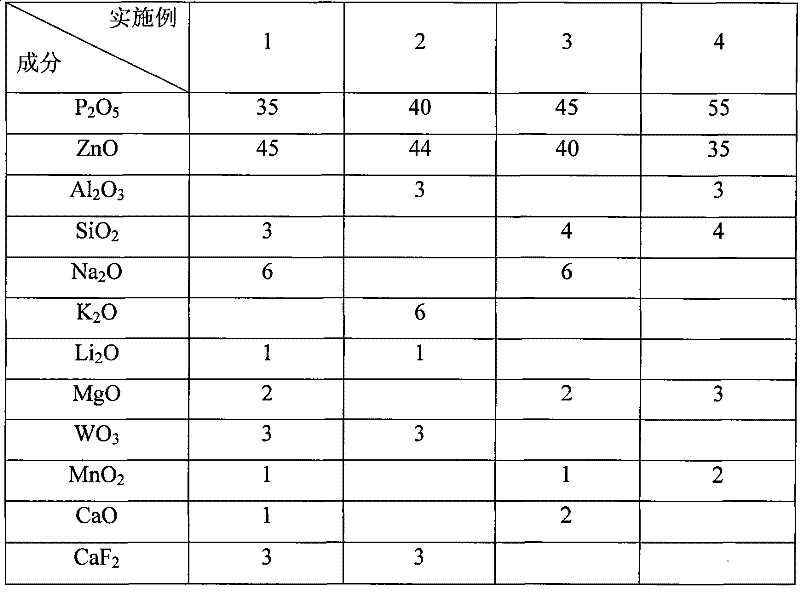

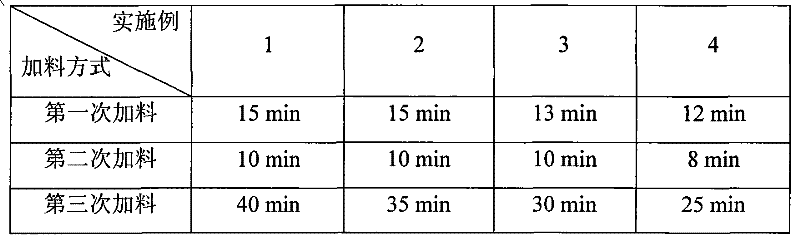

Embodiment 1

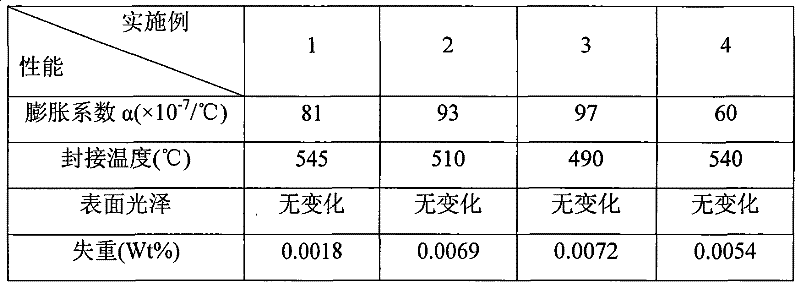

[0036] According to the composition weight percentage of Table 1, the ingredients were mixed evenly, and according to Table 3, the glass frit was put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1270°C.

[0037] The annealed sample is ground into a cylindrical sample of φ5×25mm for performance analysis: from room temperature to 300°C, the heating rate is 5°C / min, and the thermal expansion coefficient (α) is measured by a WRP-1 microcomputer thermal dilatometer; The sealing temperature is obtained through the hemispherical experiment; the change of the surface gloss is obtained by spreading the glass powder evenly on the alumina ceramic substrate, and after sintering in the muffle furnace, when the glass powder is in a leveled state, put it in a 100°C The change of surface gloss in deionized water after 1 hour of heat preservation, the gloss change is the change of gloss observed by naked eyes; the weight los...

Embodiment 2

[0040] According to the composition weight percentage of Table 1, the ingredients were mixed evenly, and according to Table 3, the glass frit was put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1250°C.

[0041] The annealed sample was ground into a cylindrical sample with a specification of φ5×25mm for performance analysis. The test results are shown in Table 2.

[0042] The melted glass is poured into a tablet press to be pressed into tablets, and then it is ball-milled into powdered glass powder, and the sieved glass powder is packaged for use by users.

Embodiment 3

[0044] According to the composition weight percentage of Table 1, the ingredients were mixed evenly, and according to Table 3, the glass frit was put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1230°C.

[0045] The annealed sample was ground into a cylindrical sample with a specification of φ5×25mm for performance analysis. The test results are shown in Table 2.

[0046] The melted glass is poured into a tablet press to be pressed into tablets, and then it is ball-milled into powdered glass powder, and the sieved glass powder is packaged for use by users.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com