Oil gas separator

A technology of oil mist separation and oil outlet, which is applied in the direction of engine lubrication, metal rolling, mechanical equipment, etc., can solve the problems of poor lubrication effect and large bubble content, and achieve cost saving, consumption saving and good lubrication effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

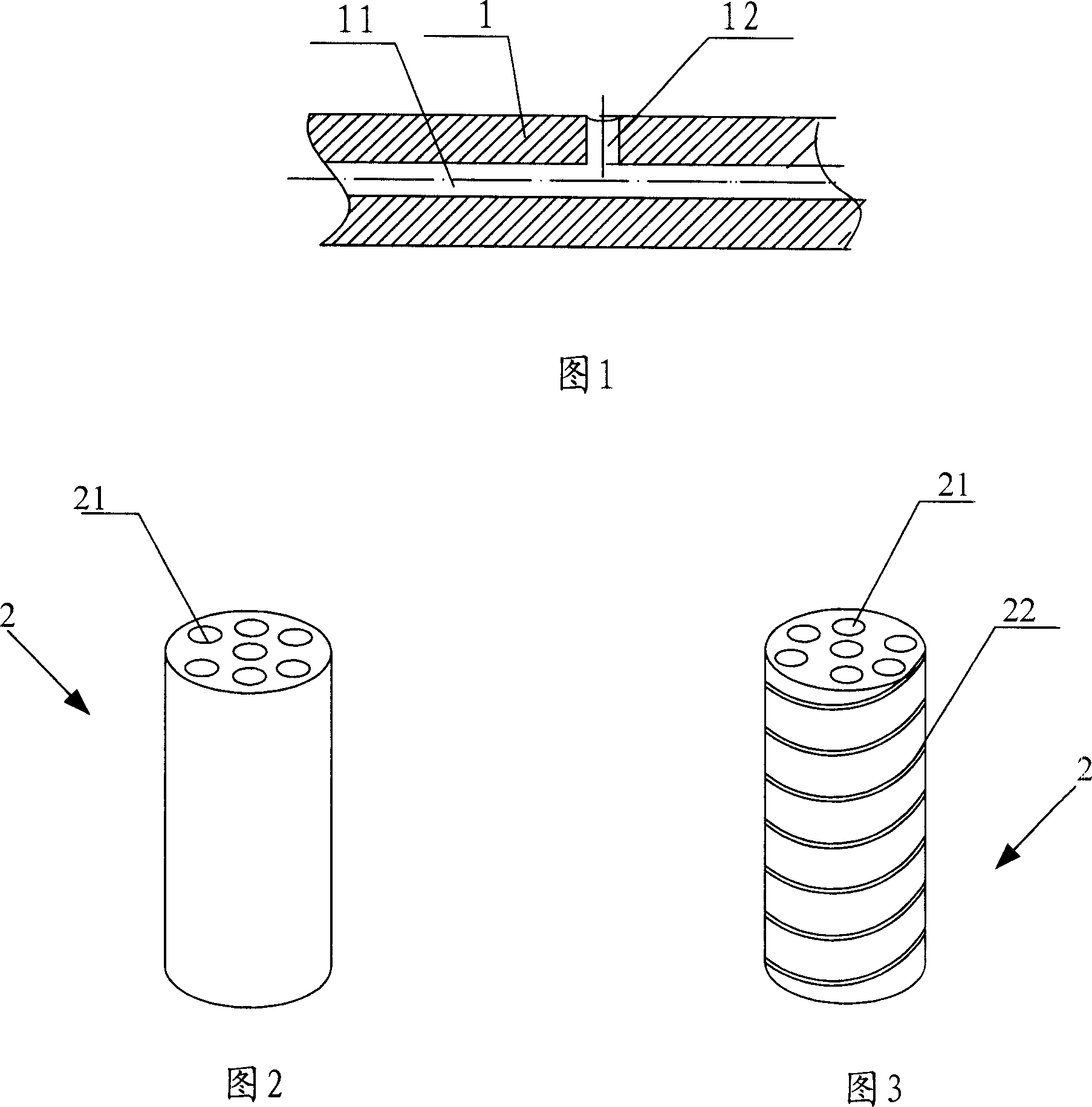

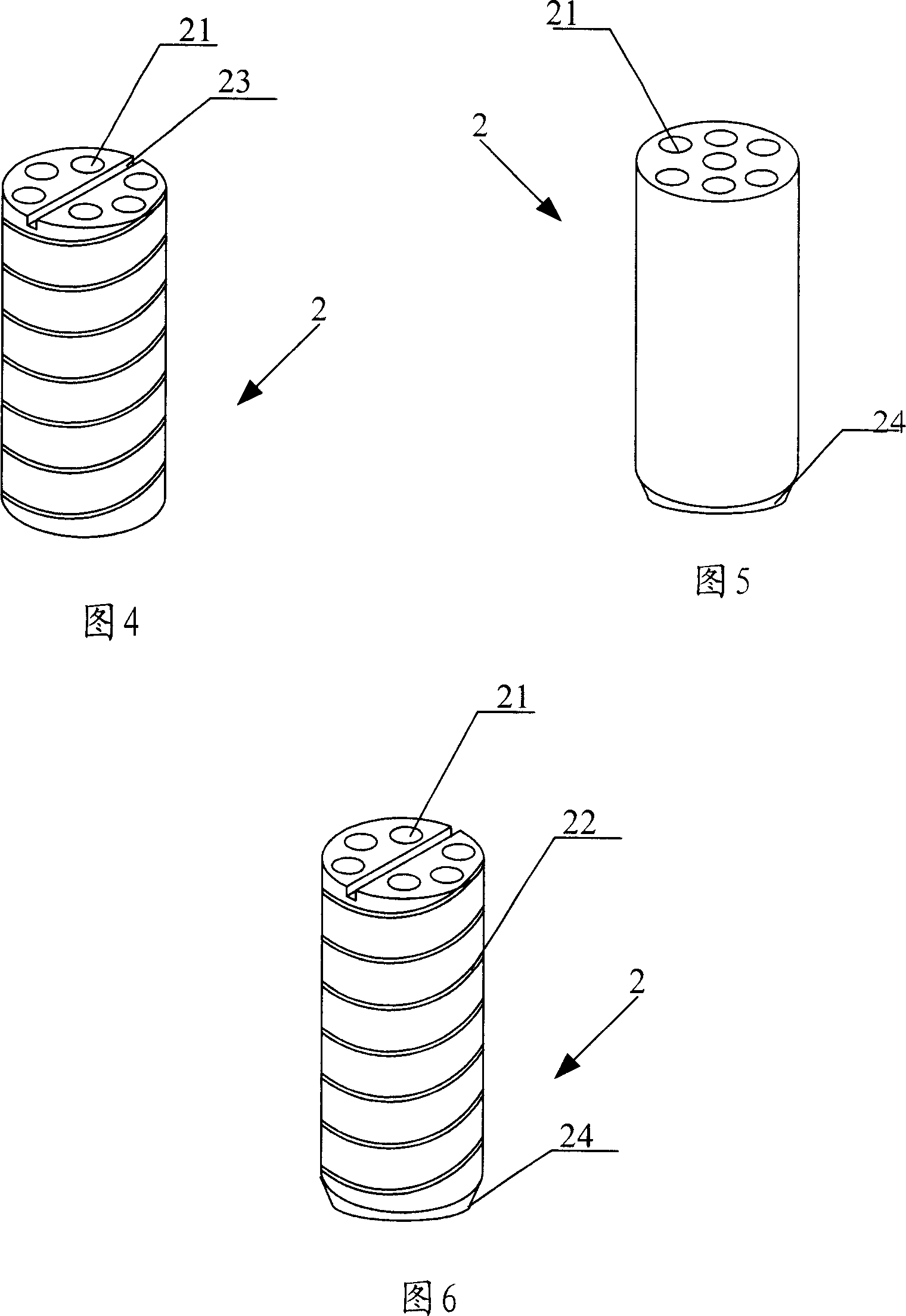

[0021] Fig. 2 is a schematic structural view of the first embodiment of the oil mist separation device of the present invention. The oil mist separation device 2 is arranged in the oil outlet hole 12 in Fig. 1, the shape of the oil outlet hole 12 is a cylinder, and the oil mist separation device 2 is a cylinder matching the shape of the oil outlet hole 12, and its upper and lower bottom surfaces Between them, one or more oil mist separation holes 21 are axially penetrated inside the cylinder, and the oil mist separation device 2 can be firmly installed in the oil outlet hole 12 through interference fit.

[0022] Fig. 3 is a schematic structural view of the second embodiment of the oil mist separation device of the present invention. The oil mist separation device 2 is a cylinder with one or more oil mist separation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com