Method for investigating noise character of converter steelmaking blowing slag-making

A noise feature and converter steelmaking technology, applied in the field of noise feature detection of converter steelmaking and slag blowing, can solve the problems of inaccurate detection and low probability of false detection by the audio slag making method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

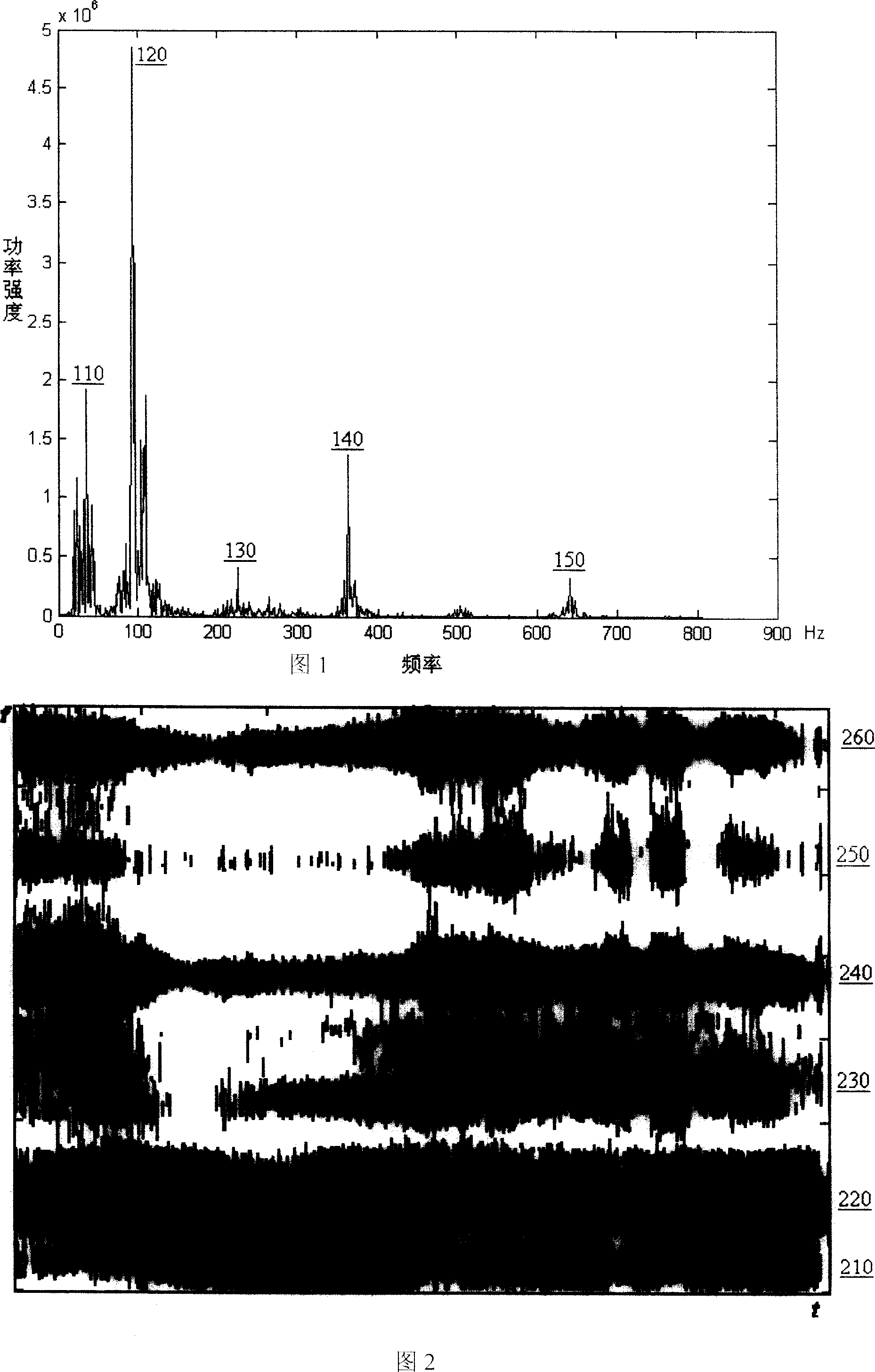

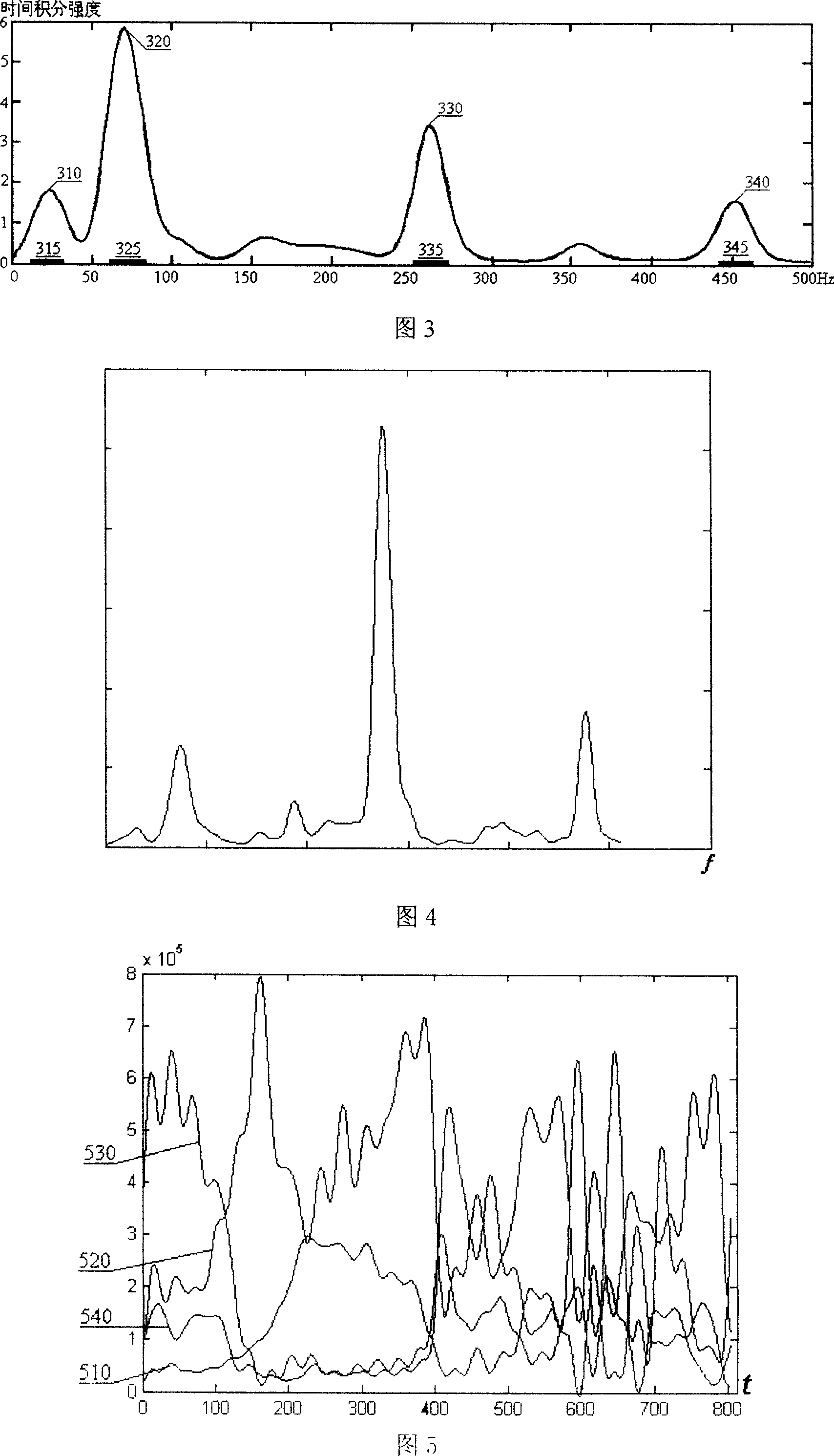

[0049]Since the blowing noise is generated by a non-stationary random process, the frequency spectrum has strong random characteristics, especially the phase is completely random, and it is difficult to analyze its trend. Therefore, the present invention uses the method of calculating its power spectrum to analyze the noise at different frequencies. The intensity distribution and its evolution characteristics on .

[0050] In the steelmaking process, the converter is a time-varying system, so the entire steelmaking process must be divided into many short time intervals, and it can be considered that the state of the converter system remains unchanged in each time interval. The power spectrum of the blowing noise is calculated in each time interval to reflect the slagging characteristics in this time period, which is called the power spectrum, as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com