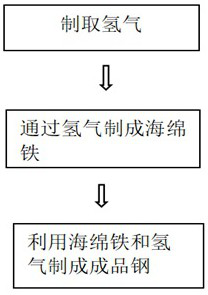

Carbon neutralization method for smelting steel and iron by using iron ore, hydrogen and oxygen

A carbon-neutral and hydrogen-based technology, applied in the field of steelmaking, can solve problems such as location and condition restrictions, cumbersome preparation work, and reduced steelmaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

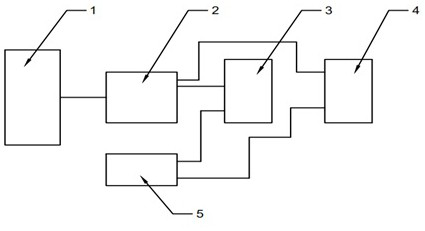

[0019] In this embodiment, a smelting gasifier 1, a flue gas separator 2, an oxygen generator 5, a heating furnace 3 and a converter 4 are included, wherein the smelting gasifier 1 communicates with the flue gas separator 2 through a gas pipeline , the flue gas separator 2 communicates with the heating furnace 3 and the converter 4 through a gas pipeline, and the oxygen generator 5 communicates with the heating furnace 3 and the converter 4 through a gas pipeline; the specific implementation steps are as follows : add combustible energy in the smelting gasifier 1, gasify to generate a mixed gas containing hydrogen and carbon dioxide, pass the mixed gas into the flue gas separator 2 for gas separation, pass the separated hydrogen through into the heating furnace 3; when hydrogen is passed into the heating furnace 3, iron ore, biological particles and oxygen produced by the oxygen generator 5 are added into the heating furnace 3, wherein the biological Particulate matter is comb...

Embodiment 2

[0021] In this embodiment, a smelting gasifier 1, an oxygen generator 5, a flue gas separator 2, a heating furnace 3 and an electric arc furnace 4 are included, and the smelting gasifier 1 communicates with the flue gas separator 2 through a gas pipeline , the flue gas separator 2 communicates with the heating furnace 3 and the electric arc furnace 4 through a gas pipeline, and the oxygen generator 5 communicates with the heating furnace 3 and the electric arc furnace 4 through a gas pipeline; specific implementation The steps are: add combustible energy into the smelting gasifier 1 for gasification to generate a mixed gas containing hydrogen, pass the mixed gas into the flue gas separator 2 to separate the hydrogen, and remove the rest of the gas through the flue gas separator ; The hydrogen is passed into the heating furnace 3, meanwhile, iron ore, biological particles and the oxygen produced by the oxygen making device 5 are also added in the heating furnace 3, wherein the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com