High-property anti-radiation quartz optical fibre and manufacturing process of combined method

A quartz fiber and anti-radiation technology, which is applied in cladding optical fiber, glass fiber products, optics, etc., can solve the problem of high fiber loss, achieve low transmission loss, improve radiation resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

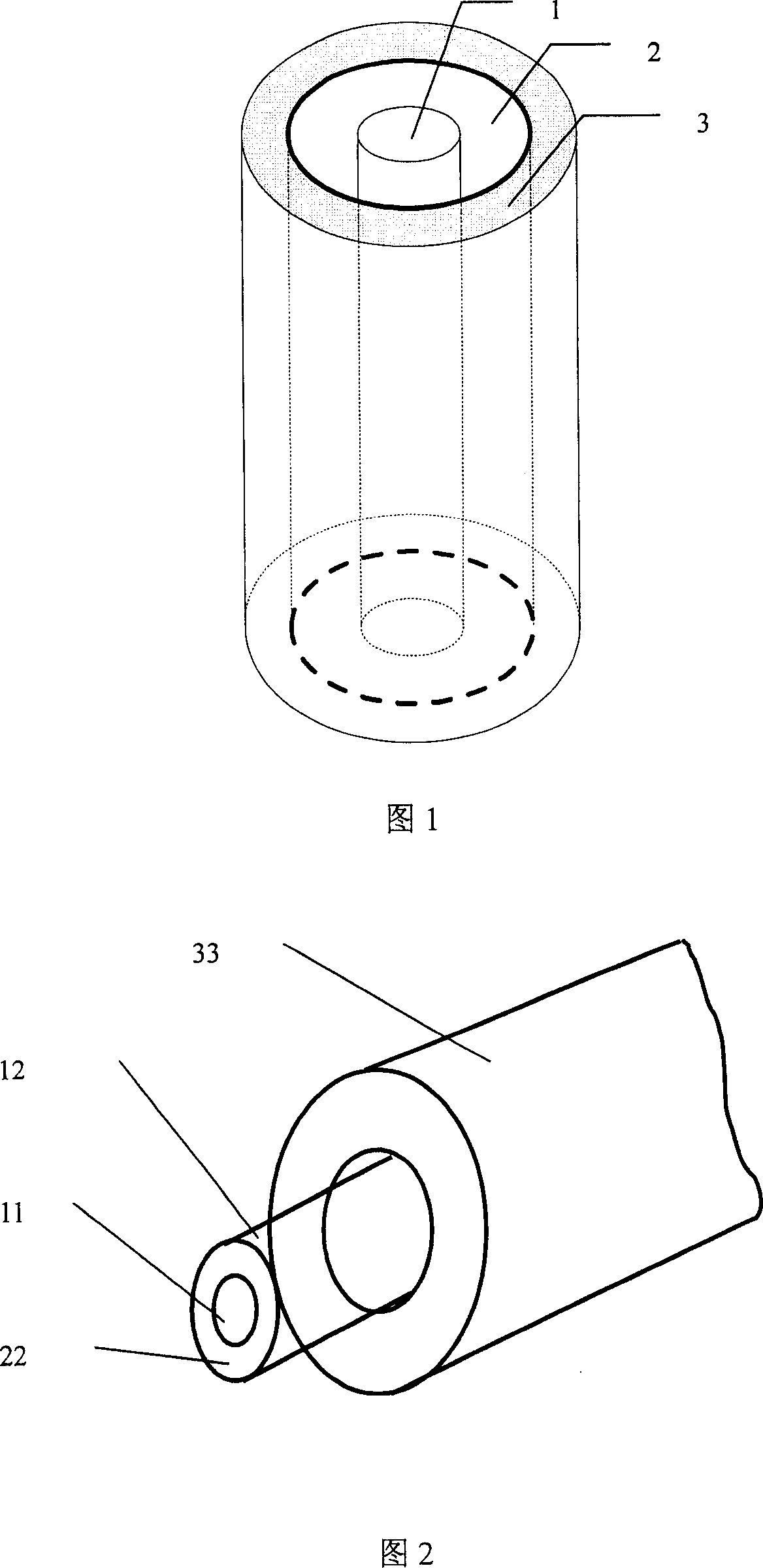

[0016] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0017] Referring to Fig. 1, this high-performance anti-radiation silica fiber is composed of a pure silica core 1, an inner cladding 2 and an outer cladding 3, the material of the quartz core 1 is a high-purity quartz material; the material of the inner cladding 2 is pure silica The matrix is doped with 250ppm of fluorine; the material of the outer cladding layer 3 is pure quartz as the matrix doped with 8000ppm of cerium.

[0018] Referring to Fig. 2, the above-mentioned high-performance radiation-resistant silica optical fiber is manufactured by a combined method: using improved vapor deposition (MCVD) or plasma chemical vapor deposition (PCVD), sequentially vapor deposition on the MCVD rod machine or PCVD The prefabricated layer 22 of the inner cladding 2 and the prefabricated core 11 of the pure silica fiber core 1 are made by the same method, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com