High-performance anti-radiation quartz optical fiber and making method thereof

A technology of quartz optical fiber and manufacturing method, which is applied in cladding optical fiber, glass fiber products, optics, etc., can solve the problem of high optical fiber loss, and achieve the effects of low transmission loss, strong radiation resistance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

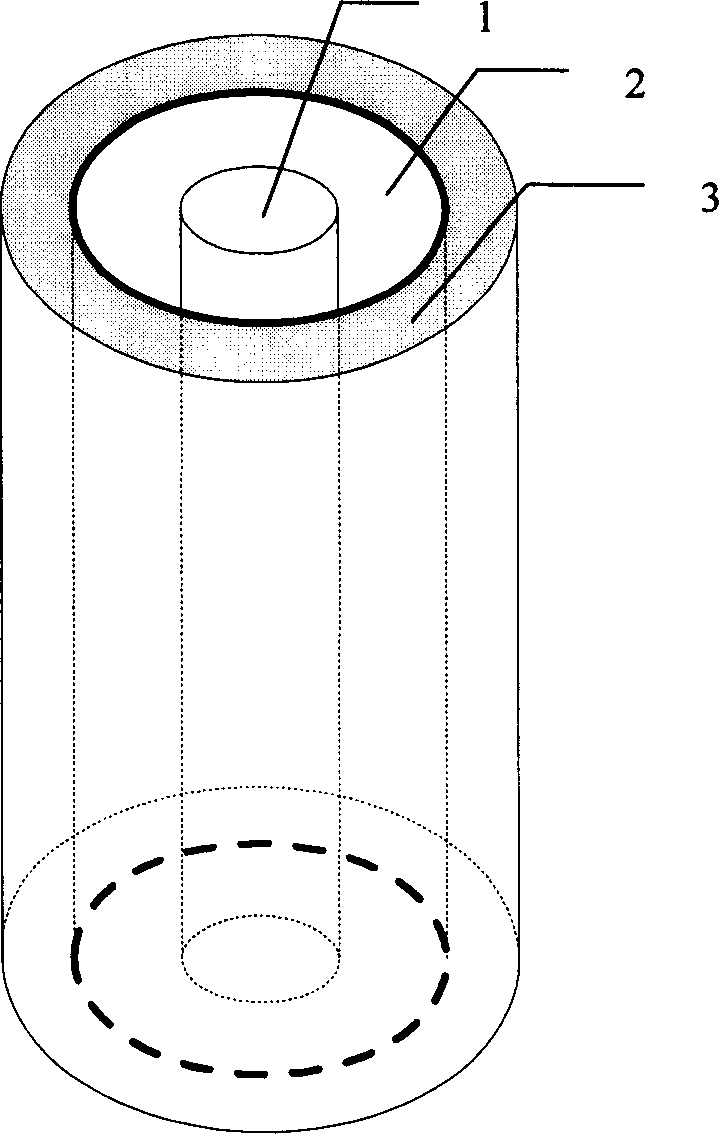

[0015] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0016] see figure 1 , the high-performance anti-radiation silica optical fiber, which is composed of core 1, inner cladding 2 and outer cladding 3, the material of core 1 is high-purity quartz material; the material of inner cladding 2 is pure quartz as matrix doped with 250ppm Fluorine; the material of the outer cladding layer 3 is pure quartz as the matrix doped with 6000ppm of cerium.

[0017] The above-mentioned high-performance radiation-resistant silica optical fiber is directly made of the outer cladding 3, the inner cladding 2 and the fiber core 1 by vapor deposition method (MCVD) on the MCVD rod making machine, and finally the rod is shrunk to form an optical fiber preform, and then It is then drawn to make an optical fiber. The above-mentioned high-performance radiation-resistant silica optical fiber can also be directly made into a core 1, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com