Acoustic board of glass fibre composite

A composite material and glass fiber technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of unsatisfactory sound insulation effect, poor durability and high cost, and achieve the effect of excellent sound absorption effect, good corrosion resistance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

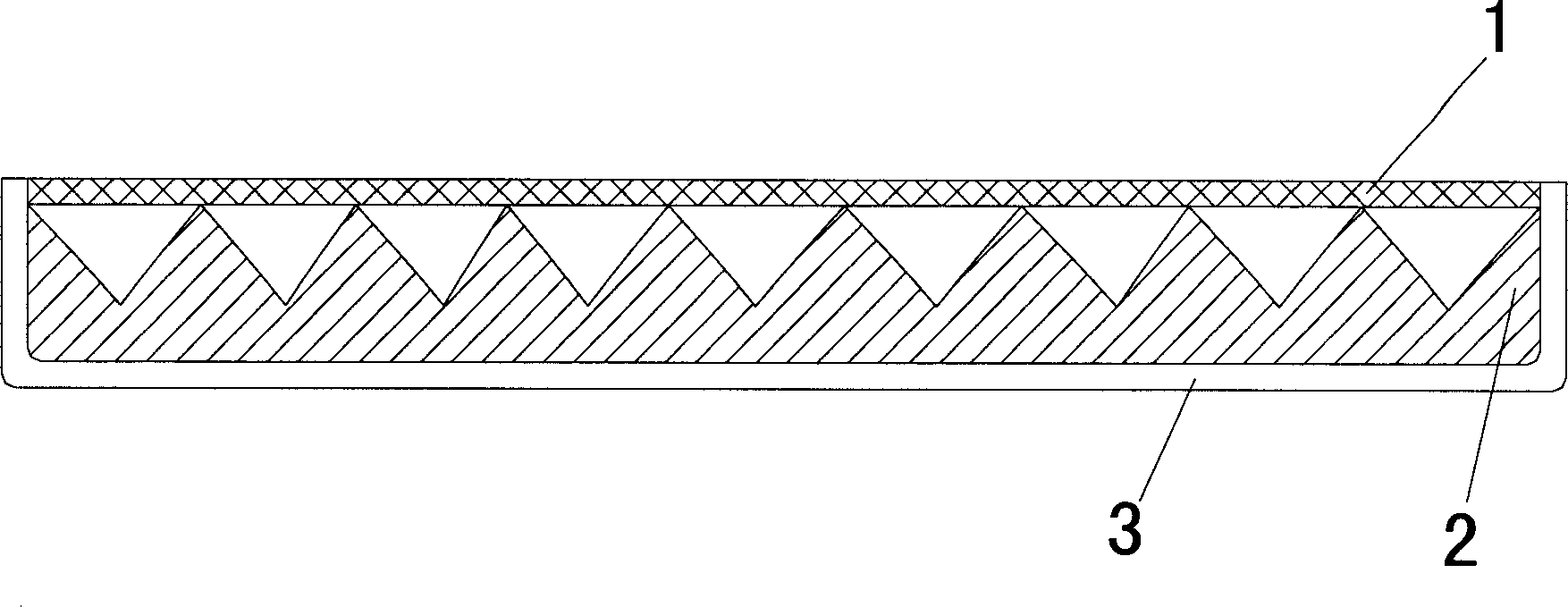

[0011] As shown in the accompanying drawings, the sound-absorbing panel of the present invention consists of a surface grid 1 , sound-absorbing cotton 2 and an outer frame 3 . The shape of the outer frame 3 is pot-shaped, which is composed of the surrounding outer walls and the bottom surface. It is produced by the method of pultrusion with glass fiber composite material. It has the characteristics of high strength, corrosion resistance, durability, light weight and low cost. It is suitable for mass production, and the external dimensions can be designed into various specifications. It can be directly pasted on the concrete sound insulation wall with resin or used alone as a sound barrier.

[0012] The outer frame 3 is built with sound-absorbing cotton 2, and the surface of the sound-absorbing cotton 2 is distributed with a tapered structure, so that the principle of the sound-absorbing wedge can be used to make the average oblique incidence sound absorption rate reach 96%, fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com