Developing roller and imaging apparatus using the same

A developing roller and developer technology, which is applied to the electric recording process using charge patterns, equipment and instruments for electric recording processes using charge patterns, etc., can solve the problems that carbon materials cannot be used and resin curing cannot be fully carried out, etc. Achieve the effect of saving large-scale equipment and space, and suppressing uneven film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0226] The present invention will be described in detail below through examples and comparative examples, but the present invention is not limited to these examples.

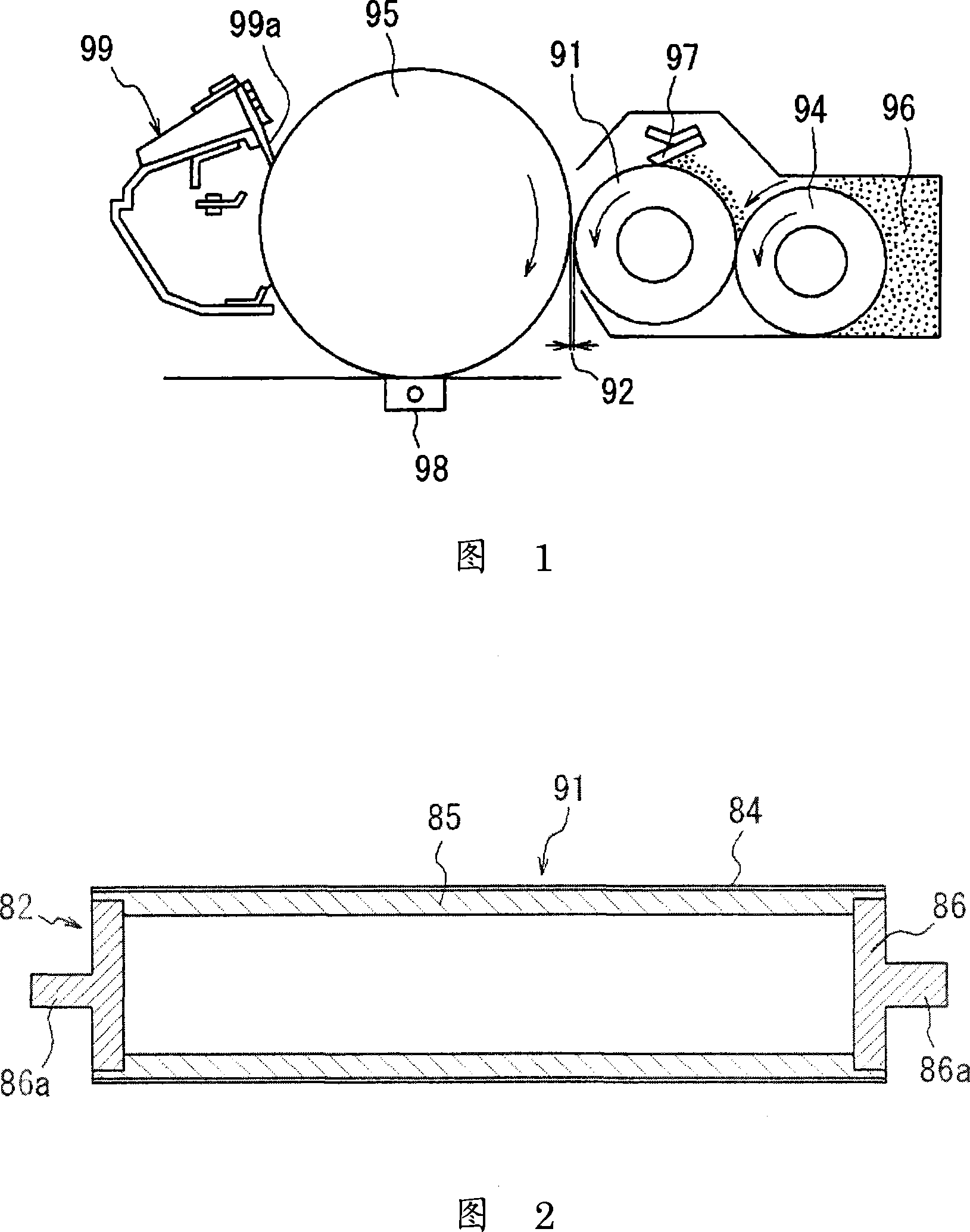

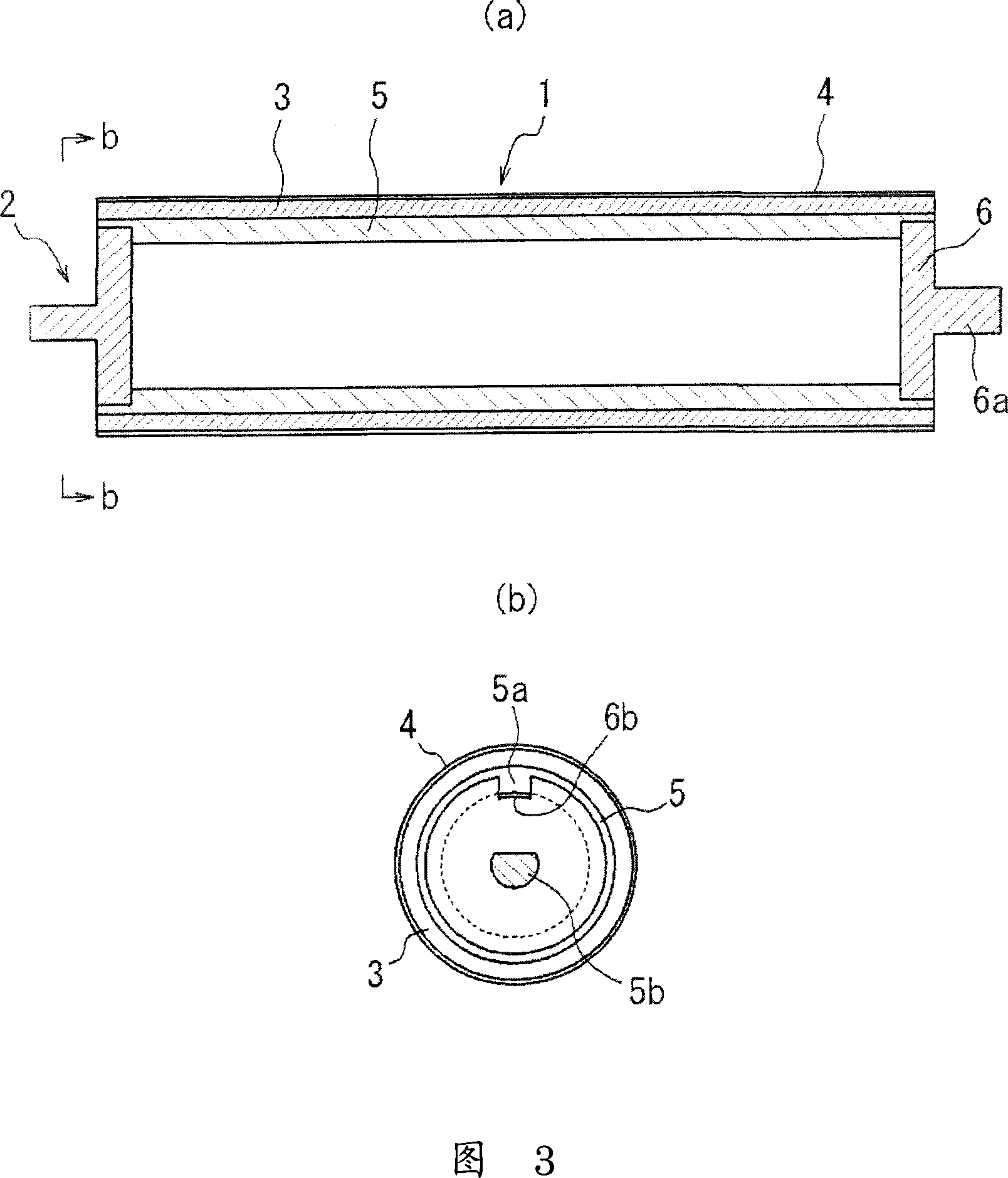

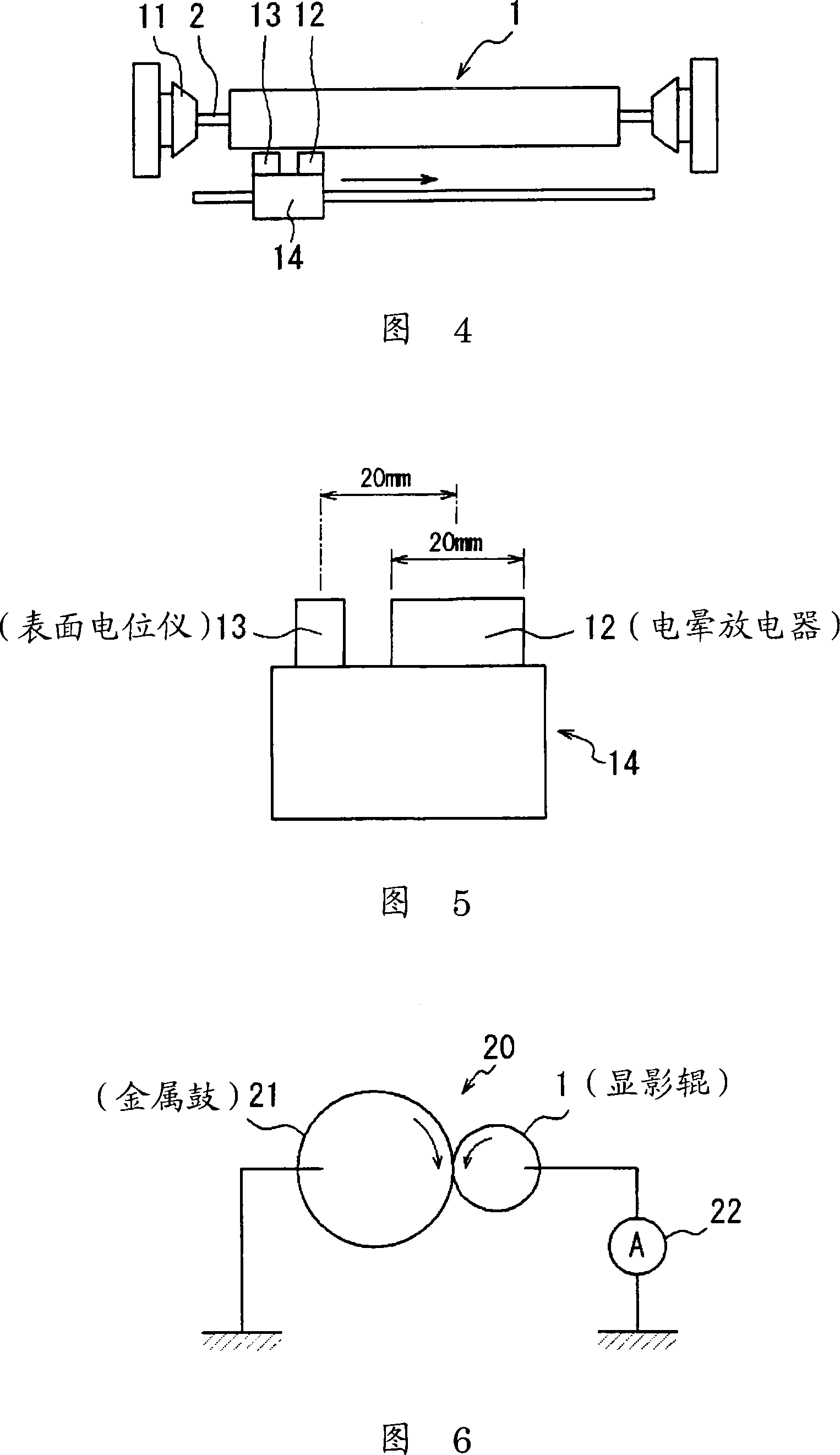

[0227] When the developing roller does not have an elastic layer, a resin layer is formed directly on the shaft member made of an aluminum tube, or when the developing roller has an elastic layer, after the elastic layer is formed on the shaft member, a resin layer is formed to manufacture as shown in Fig. 3 The developing roller of the structure was used as an example, and in order to compare with the developing roller of the example, a developing roller having a partly different composition from that of the present invention was manufactured as a comparative example. Furthermore, with respect to the developing rollers of these Examples and Comparative Examples, measurement evaluation of roller characteristics and image evaluation were performed.

[0228] The material table showing the materials used to form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com