Super high pressure mould of six top surfaced diamond synthesis pressure equipment

A diamond and ultra-high pressure technology, applied in the field of ultra-hard material production, can solve the problems of high cost, difficult process control, and high cost of ultra-high pressure molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

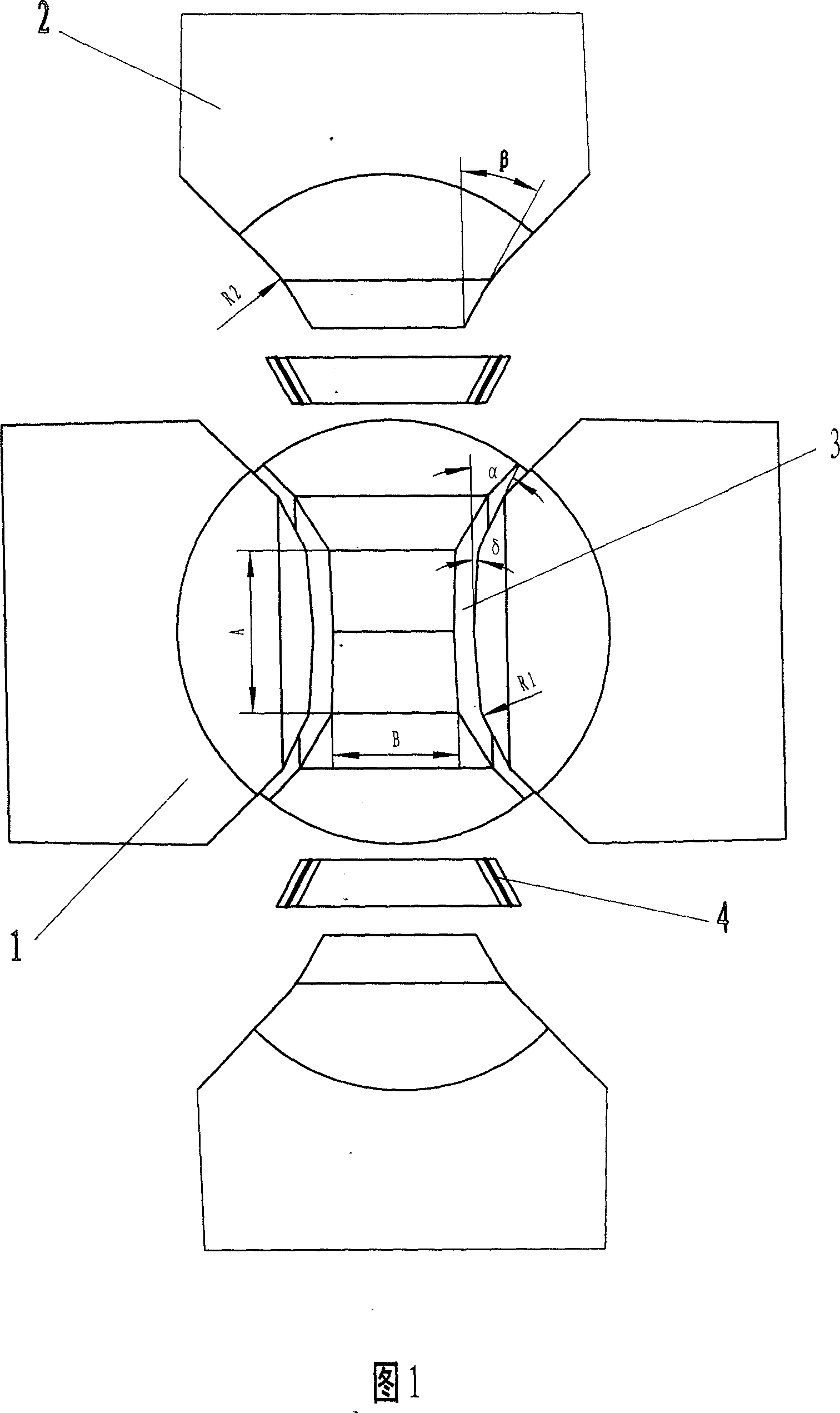

[0014] Embodiment 1, as shown in Figure 1, the ultra-high pressure mold of the six-sided top press machine is composed of four non-heating anvils 1 in the horizontal direction and two heating anvils 2 in the vertical direction, and the hammers of the four non-heating anvils 1 The linear size ratio A:B between the heated surface and the non-heated surface is 1:1.3, and the hammer surface of the non-heated anvil 1 is a ridge-shaped surface that protrudes from both sides of the hammer surface along the heating direction to the center of the hammer surface at δ=4° The angle of the sealing surface matched with the sealing surface of the heated anvil 2 is α=20° and it transitions with the 4° arc of the hammer surface. The angle of the sealing surface between the non-heated anvils 1 still adopts the original six-sided top The sealing angle of the top hammer may be slower than that of the original six-sided top hammer. When the sealing surfaces between the four non-heating top hammers ...

Embodiment 2

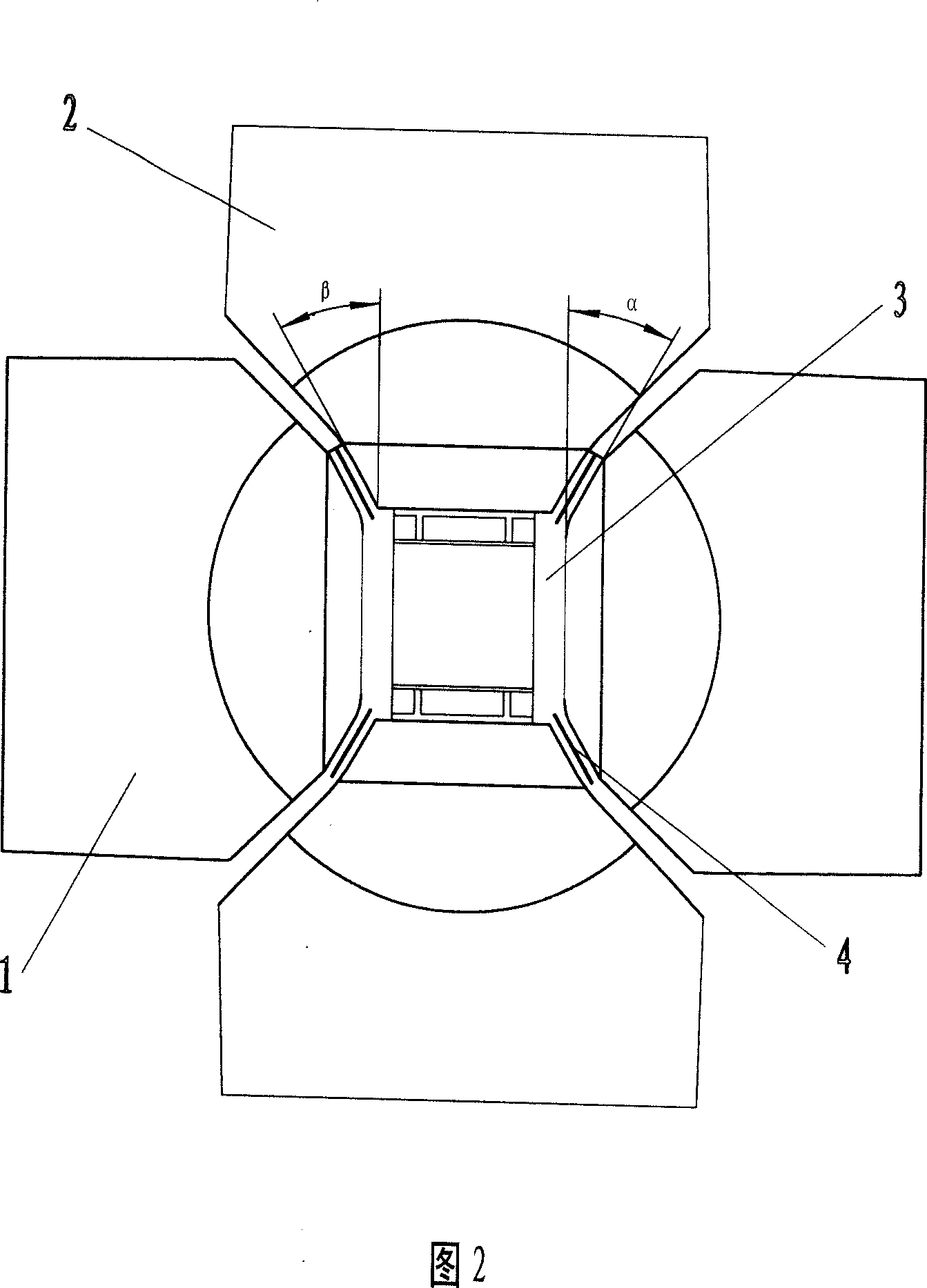

[0015] Embodiment 2, as shown in Figure 2, the ultra-high pressure mold of the six-sided top press machine is composed of four non-heating anvils 1 in the horizontal direction and two heating anvils 2 in the vertical direction, and the hammers of the four non-heating anvils 1 The straight-line size ratio A:B of the heated and non-heated surfaces is 1:1.1, the hammer surface of the non-heated anvil 1 is a plane (δ=0°), and the sealing surface angle α matching the sealing surface of the heated anvil 2 is 30°. The angle β of the sealing cone surface of the heating anvil 2 is 30°, which is parallel to the corresponding sealing surface of the non-heating anvil 1. There is also a square cone-shaped sealing gasket 4 between the sealing surfaces of the heated top hammer 2 and the non-heated top hammer 1 of the ultra-high pressure chamber. Since the angle of the sealing surface of the heating anvil 2 is equal to the angle of the sealing surface of the non-heating anvil 1 matched with ...

Embodiment 3

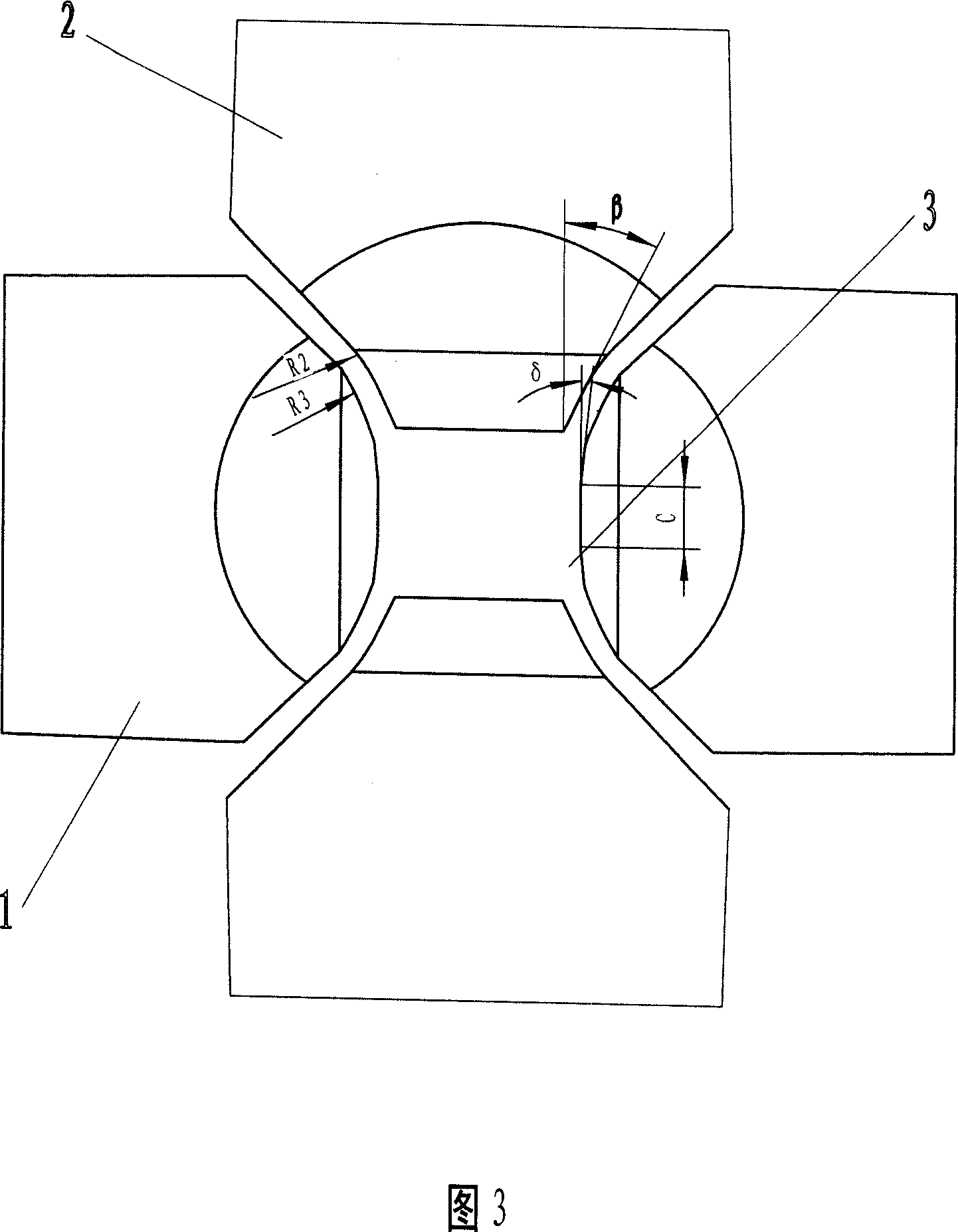

[0016] Embodiment 3, as shown in Figure 3, the ultra-high pressure mold of the six-sided top press machine is composed of four non-heating anvils 1 in the horizontal direction and two heating anvils 2 in the vertical direction, and the hammers of the four non-heating anvils 1 The straight-line dimension ratio A:B of the heated surface and the non-heated surface is 1:0.9, and the hammer surface of the non-heated anvil 1 is a ridge-shaped surface protruding from both sides of the hammer surface along the heating direction to the center of the hammer surface at δ=3° The frustum surface formed by cutting off the top of the ridge, the middle part of the hammer surface is a plane with length = C, and the sealing surface matched with the sealing surface of the heating anvil 2 is an arc surface, and the radius of curvature is R3. The angle β of the sealing surface of the heating anvil 2 is 35°, and there is an arc transition between the large slope and the radius of the arc is R2. R2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com