Device for generating large-cavity ultrahigh hydrostatic pressure

A hydrostatic pressure, large cavity technology, applied in the application of ultra-high pressure process, etc., can solve the problems of low pressure conversion efficiency, high maintenance cost, complex structure, etc., to achieve improved pressure transmission capacity, superior overall performance, and improved The effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

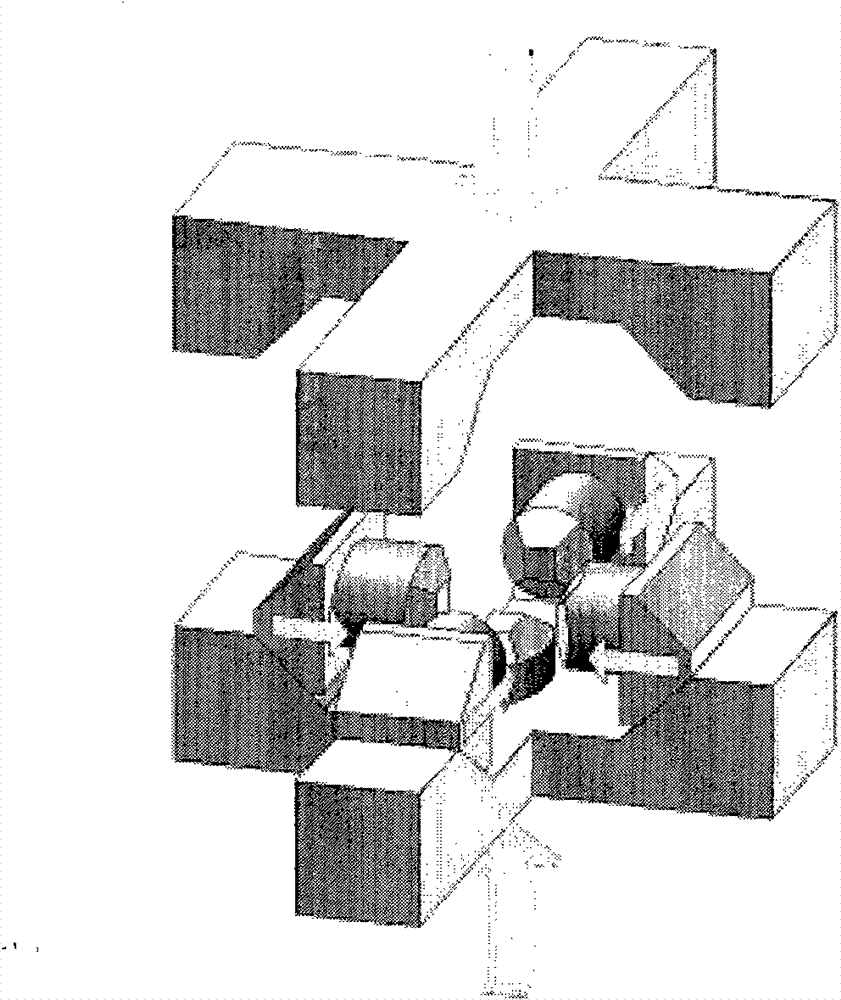

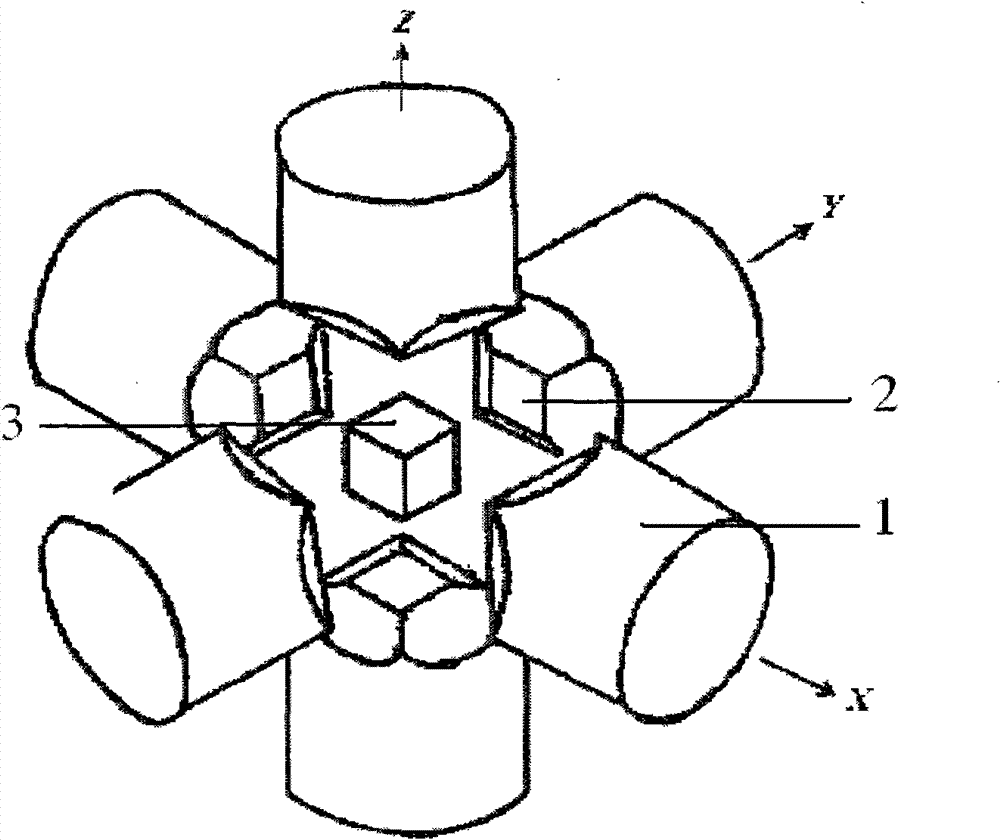

[0021] The novel device for producing ultra-high hydrostatic pressure of the present invention, its structure is as figure 2 As shown, it is a hexahedral large-cavity ultra-high hydrostatic pressure device with a hinged six-sided pressing mechanism frame. The device includes six anvils 1 (ie top hammers) driven by a six-sided top press and a hexahedron synthetic block 3 for internally containing synthetic materials. In order to make six pressure anvils 1 continue to apply pressure to the composite block 3 after contacting the hexahedron composite block 3, the size ratio of the anvil face size of the pressure anvil 1 and the size ratio of a face of the composite block 3 is preferably 0.7 (the ratio range is between 1 to 0.2).

[0022] ①If the anvil material is WC, the maximum pressure of the high-pressure synthesis chamber can reach 10GPa when the two side lengths of the anvil surface are 6mm;

[0023] ②When the length of two sides of the anvil surface is 4mm, the maximum pr...

Embodiment 2

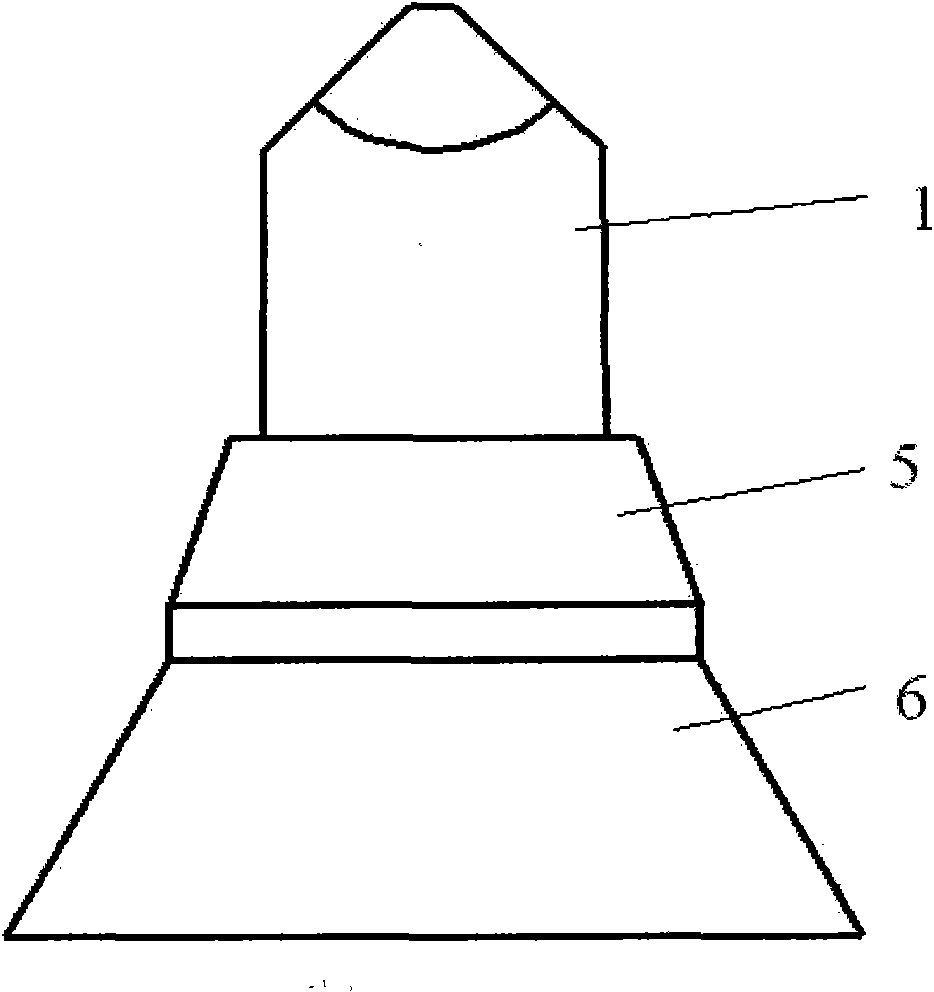

[0028] See image 3 . image 3 Among them, 1 is an anvil, 5 is a tungsten carbide pad, and 6 is an alloy steel pad.

[0029] Adding a tungsten carbide pad 5 between the original alloy steel pad 6 and the anvil 1 can protect the alloy steel pad 6 from being crushed or indented. Because the diameter of the anvil 1 used in the present invention is relatively small, the pressure acting on the block is very large, which easily destroys the original alloy steel block 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com