Method for producing fluidified fuel of marsh gas, and dedicated measurable fluidified jar of marsh gas

A production method and liquefaction tank technology, applied in the field of processing and producing biogas liquefied fuel, to achieve the effects of extending the industrial chain, improving economic benefits, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

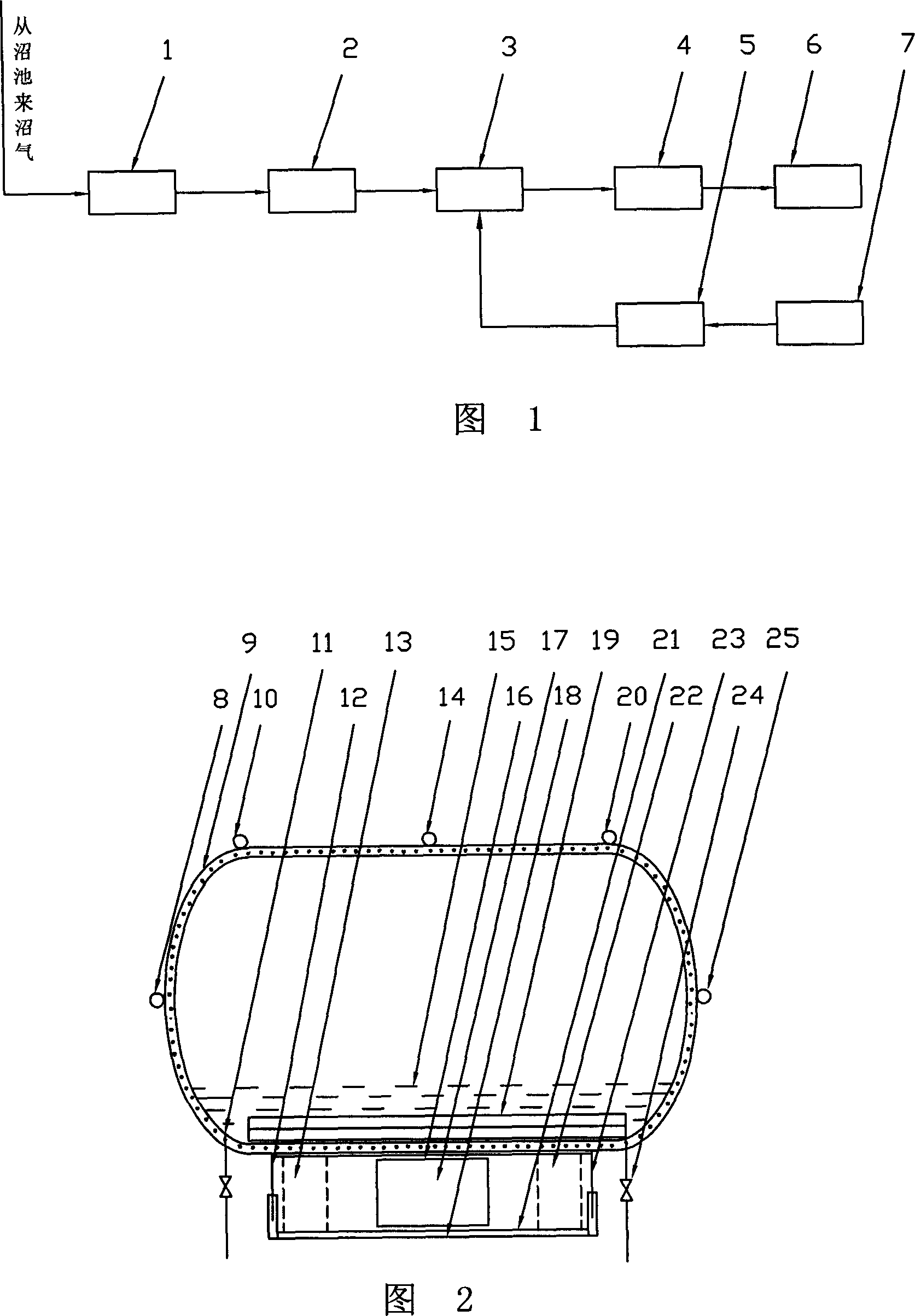

[0014] A method for producing biogas liquefied fuel. The block diagram of the production process and technical equipment of this method is shown in Figure 1: the biogas is sent to the low-pressure gas tank through the gas transmission pipe, and is compressed by the special gas compressor under automatic control and sent to the metered biogas liquefaction tank pre-installed with co-solvent , the compressed biogas is sprayed out from numerous micropores through the microporous gas injection pipe group device connected with the air intake safety check valve, passes through the co-solvent liquid layer, and releases the burst pressure energy of the biogas at the junction with the co-solvent liquid Large phenomenon - the so-called energy-gathering effect of micropores, which obtains enough metamorphic energy to undergo liquefaction metamorphosis and transform into liquefied biogas; the co-solvent is a mixed liquid of a certain amount of combined components of liquid-phase low-molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com