Dual field plate mesfet and its forming method

A field-effect transistor and metal-semiconductor technology, applied in the field of metal-semiconductor field-effect transistors, can solve problems such as channel burnout, limiting MESFET high-voltage operating characteristics, limiting MESFET operating range and robustness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

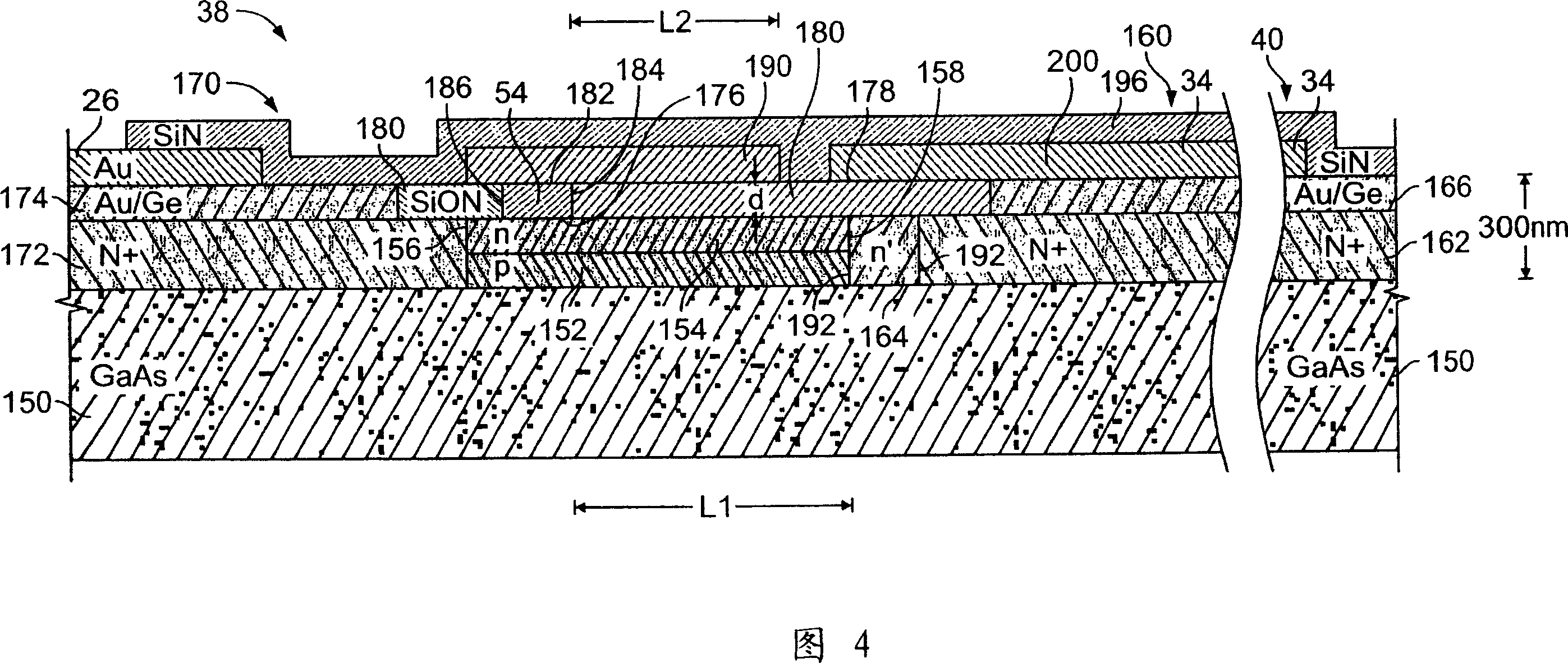

[0015] Various embodiments of the present invention provide a metal semiconductor field effect transistor (MESFET) with a drain side field plate. More specifically, in addition to the gate Schottky and the gate-side field plate extending toward the drain contact, various embodiments of the MESFET include a drain-side field plate extending toward the gate contact. The formation of the drain side field plate may be provided simultaneously with the formation of the gate field plate.

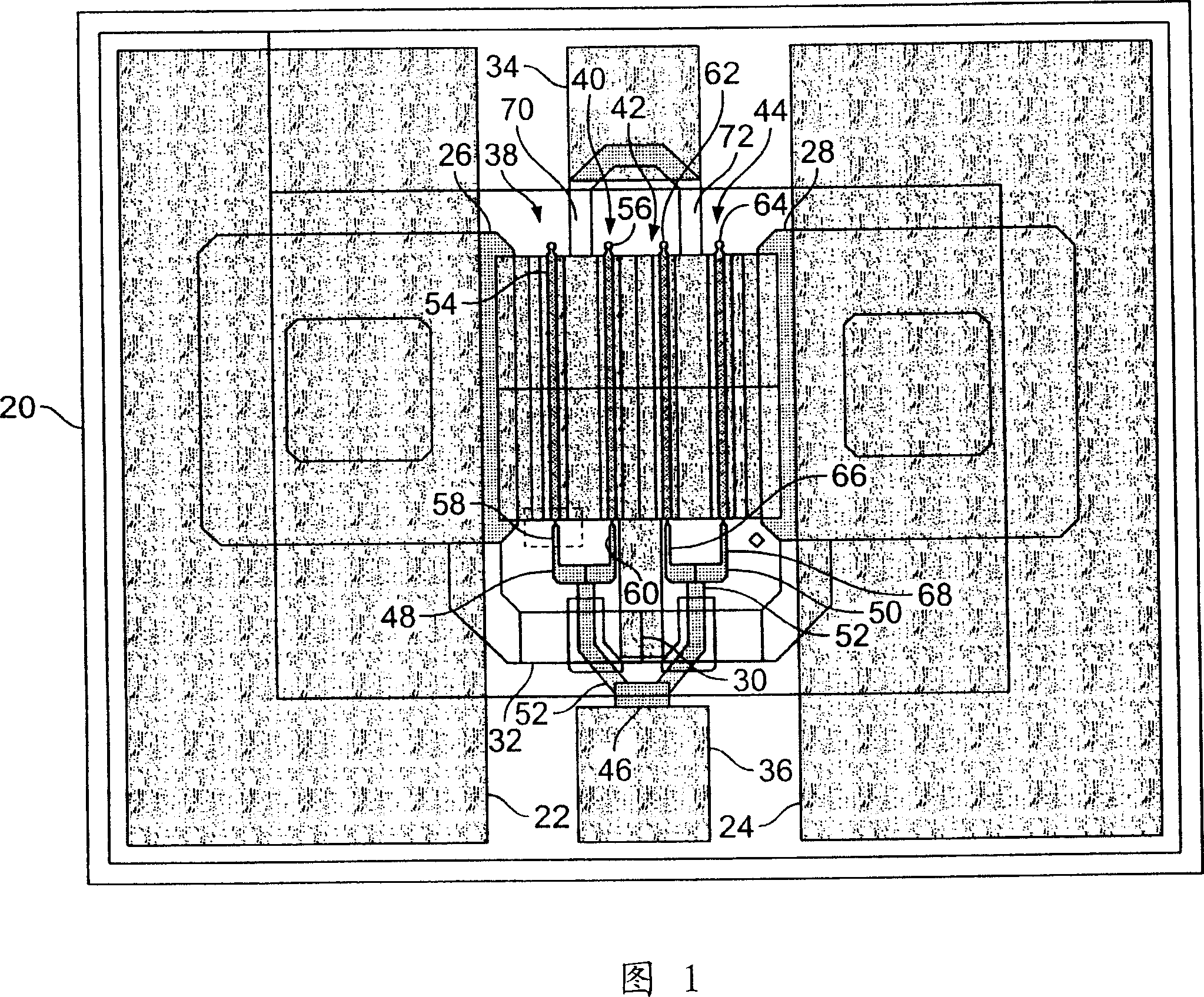

[0016] Generally, as shown in FIG. 1 , one or more MESFETs formed in accordance with various embodiments of the present invention are formed on a die 20 . More specifically, first ground plane 22 and second ground plane 24 include metal or metallization portions 26 , 28 , and 30 that define conductors or electrodes that are electrically coupled in parallel through conductive paths 32 . A drain electrode 34 configured as a contact or solder pad and a gate electrode 36 which may also be configured as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com