Turbine nozzle support device and steam turbine

A turbine nozzle and supporting device technology, applied in the field of steam turbines, can solve the problems of increased cost of steam turbines, steam leakage, inability to maintain fastening force, etc., and achieve the effect of improving the internal efficiency of the turbine and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

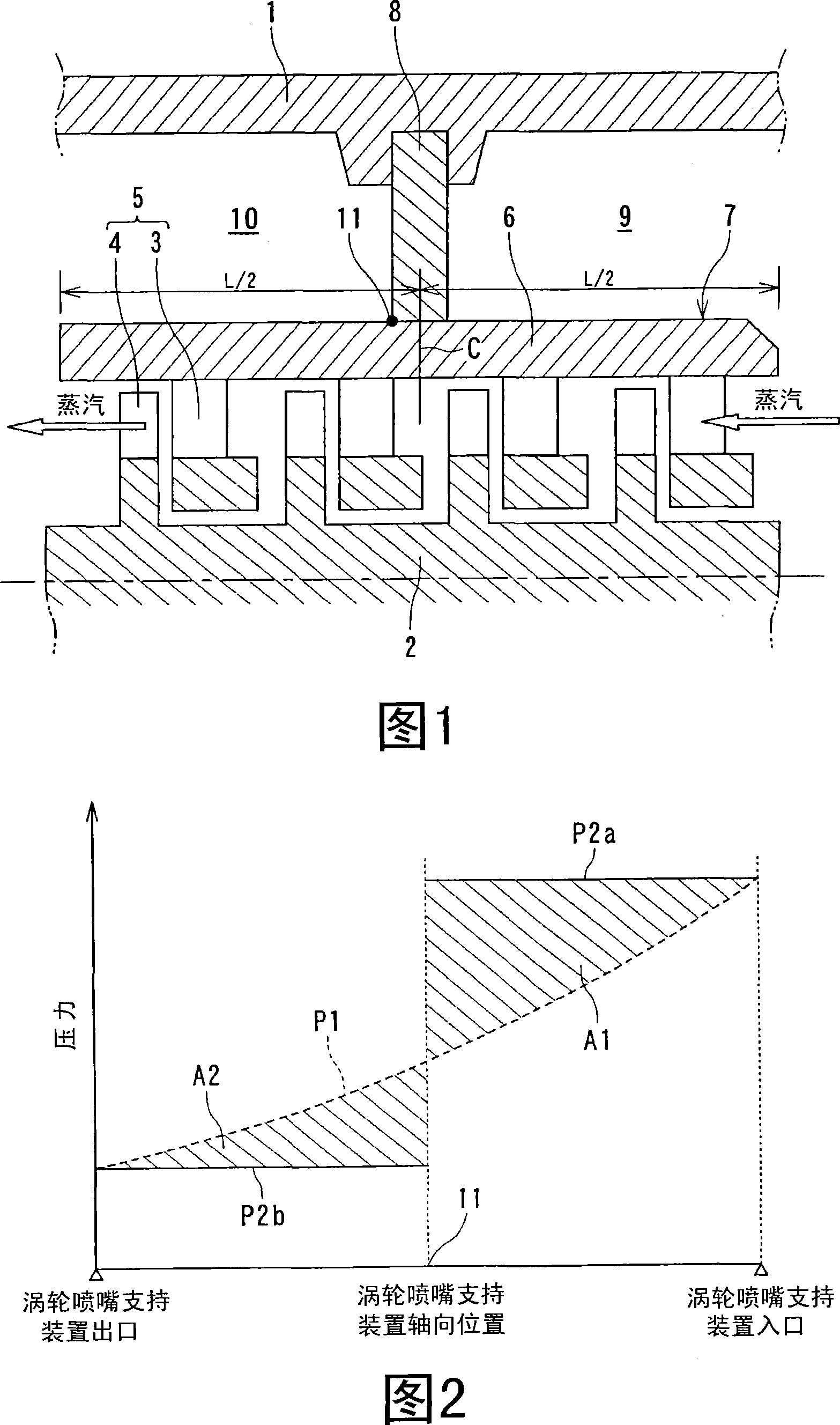

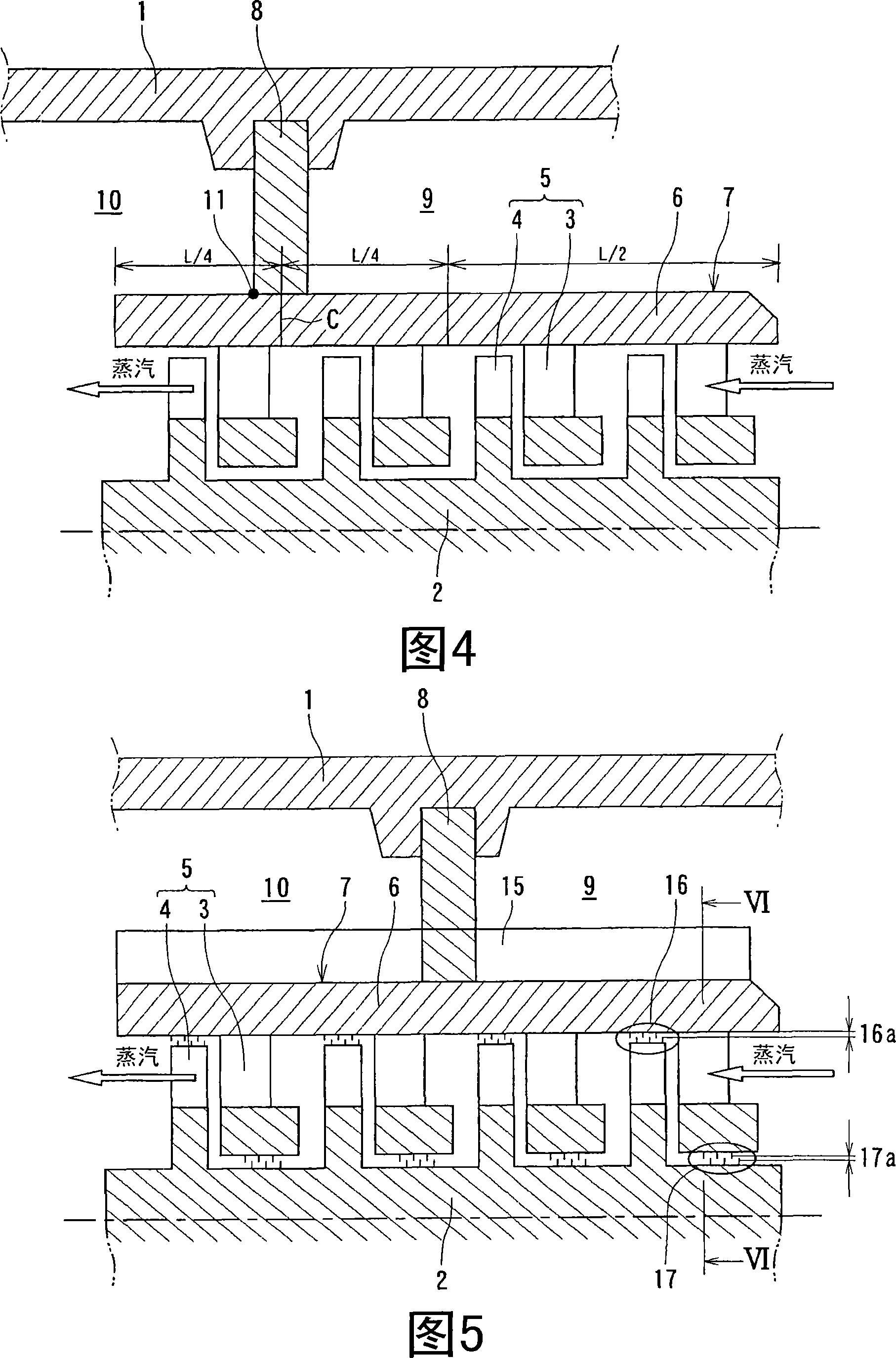

[0044] Hereinafter, embodiments of a turbine nozzle support device and a steam turbine according to one embodiment of the present invention will be described with reference to the drawings and the symbols of the drawings.

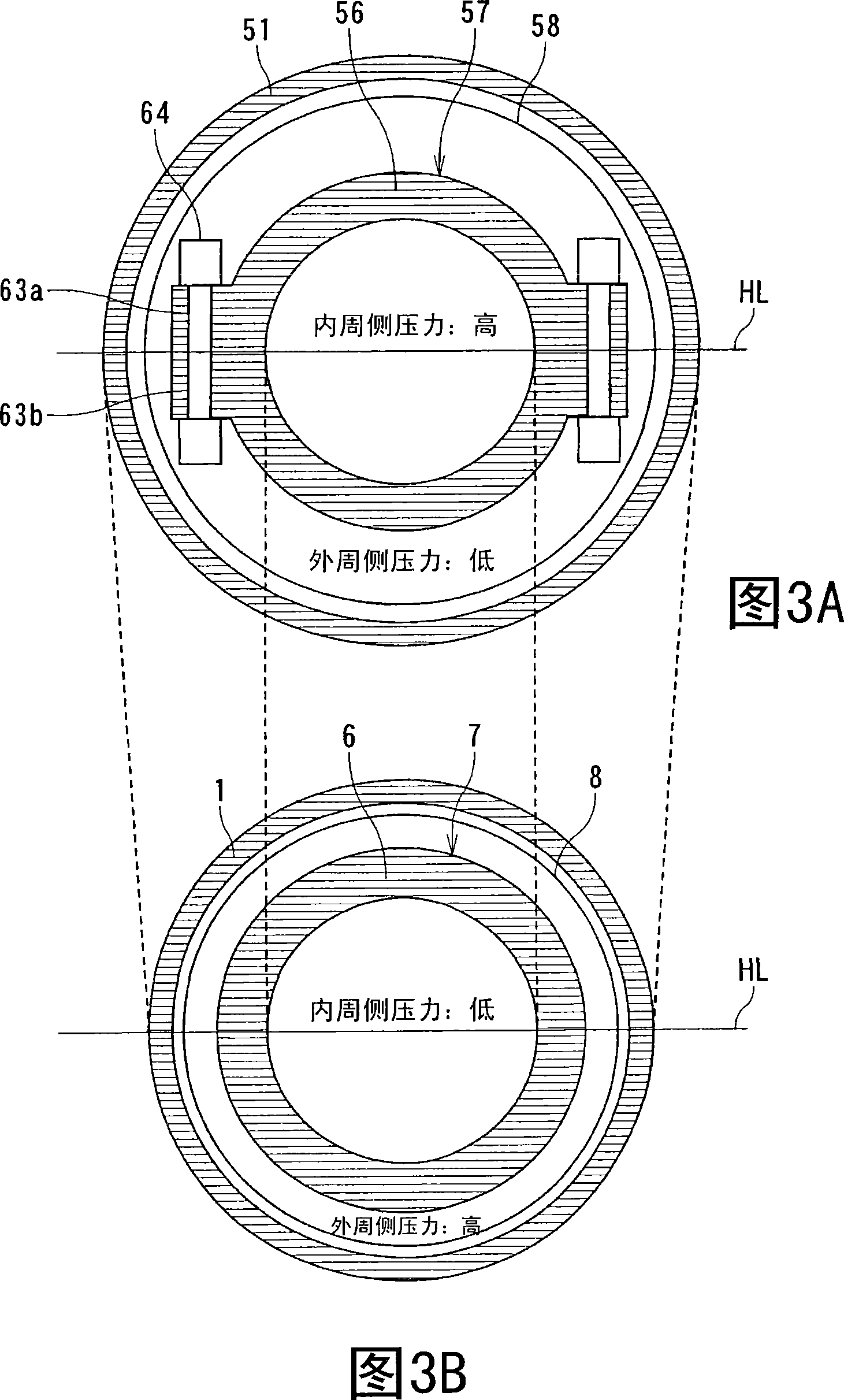

[0045] FIG. 13 is a schematic cross-sectional view in the longitudinal direction of the steam turbine according to this embodiment. A steam turbine typically has pressure zones for a high-pressure turbine, an intermediate-pressure turbine, and a low-pressure turbine. Fig. 13 shows the high-pressure turbine and the medium-pressure turbine among them. As shown in FIG. 13 , the high-pressure turbine and the medium-pressure turbine in each pressure zone of the aforementioned steam turbine are integrally arranged in one turbine housing 1 . Each of the high-pressure turbine and the intermediate-pressure turbine includes turbine rotor blades 3 fitted in the circumferential direction of the turbine rotor (rotating shaft) 2 , and turbine rotor blades 3 that are pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com