Servo-actuated die cutting scale apparatus for steel pipe

A steel pipe and fixed-to-length technology, which is applied to pipe shearing devices, shearing devices, accessories of shearing machines, etc., can solve problems such as affecting the physical and mental health of construction workers, failing to meet environmental protection requirements, and increasing the length of production lines. The effect of low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

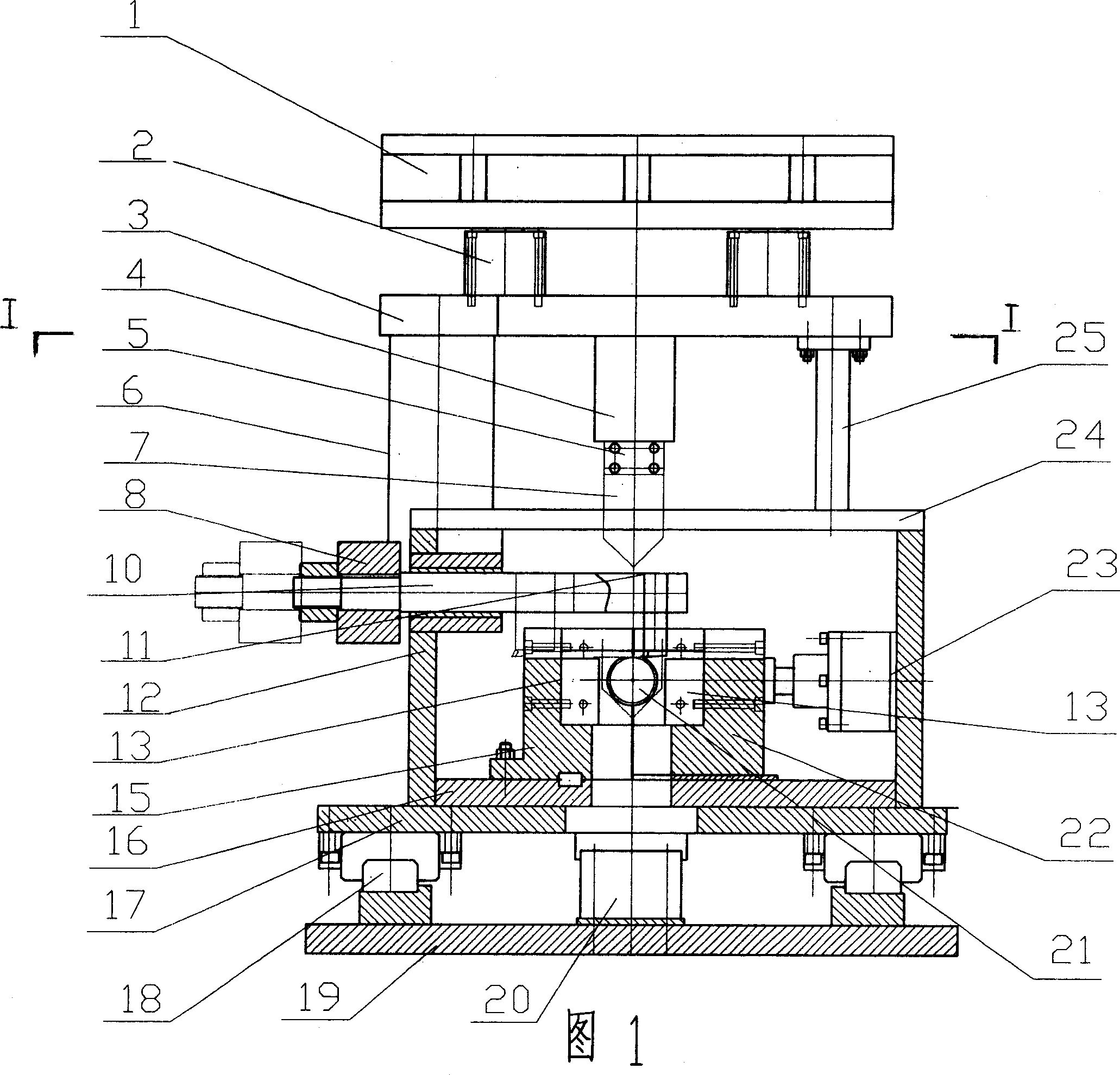

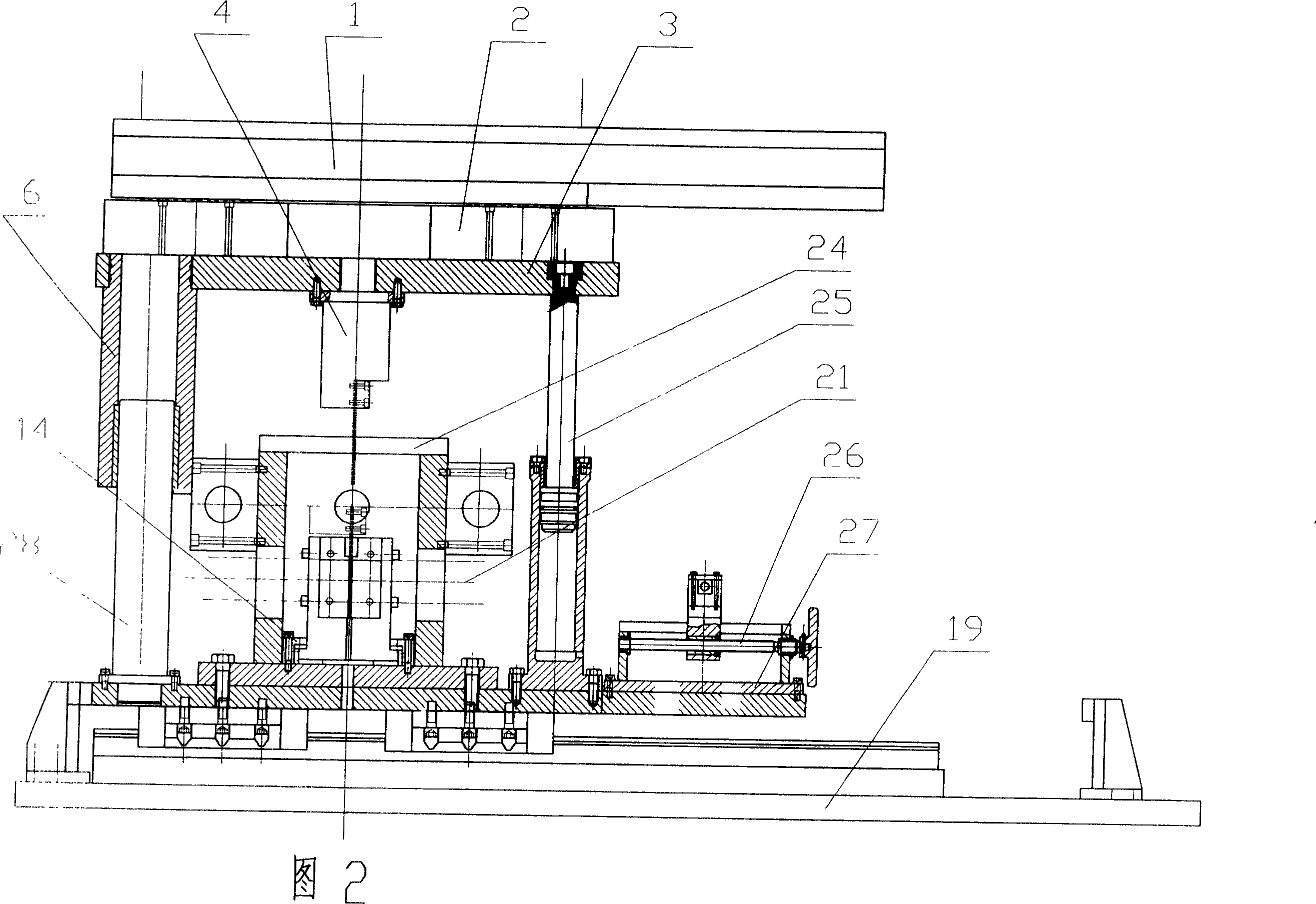

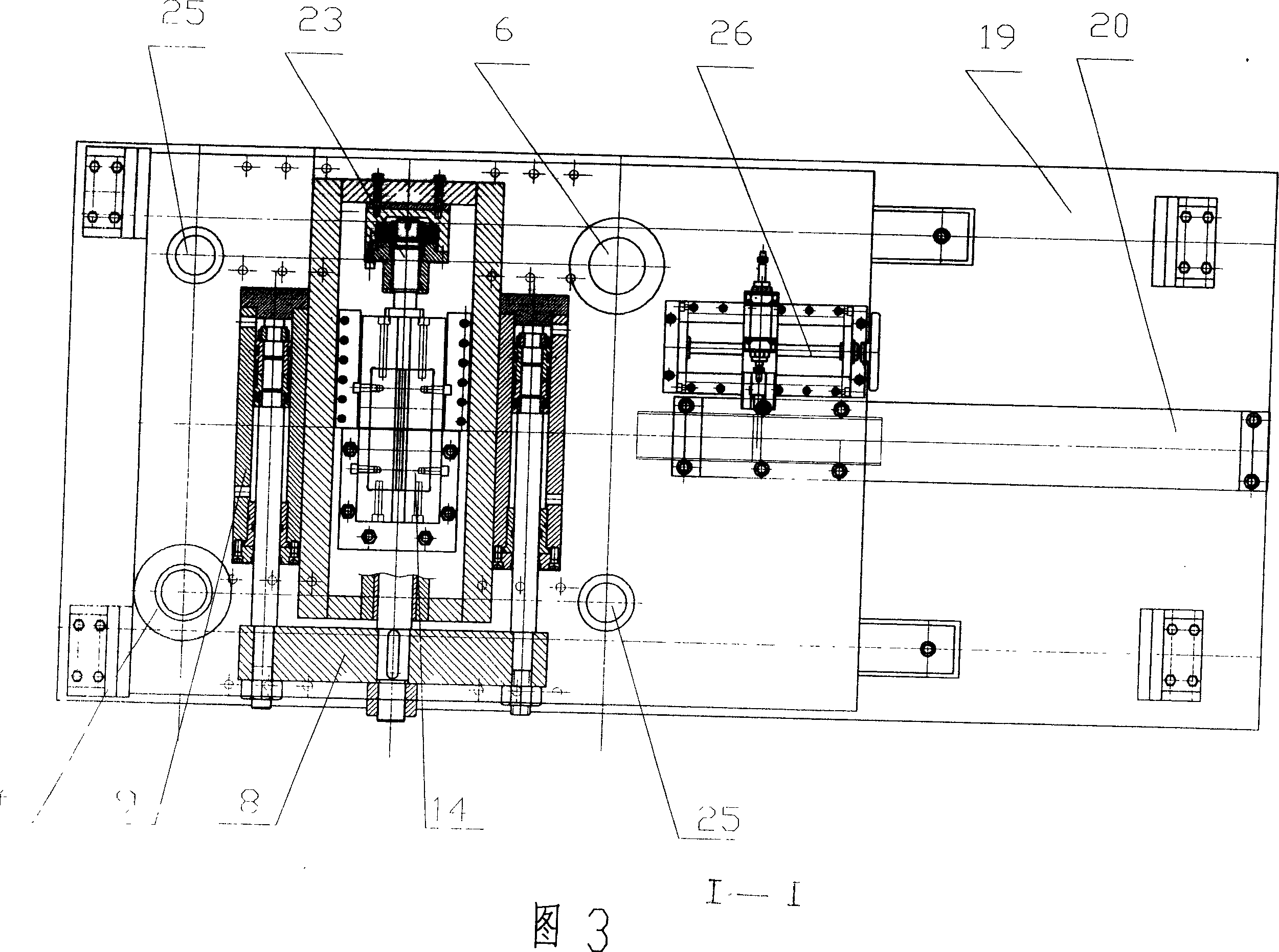

[0022] Shown in Fig. 1, 2, 3 is the specific embodiment of the present invention, and it is to manufacture below ∮ 100mm, and the follow-up punching-to-length device of the steel pipe on the production line of the carbon steel pipe below 5mm in pipe wall thickness is characterized in that: its The structure is mainly composed of upper workbench 1, ball support block 2, support plate 3, machine base 19, ball guide rail 18, trolley plate 17, guide column 28, guide sleeve 6, mold base, rodless cylinder 20, clamping mechanism, The broaching mechanism, the cutting knife mechanism, and the measuring device 26 are composed of a ball support block 2 supported by a support plate 3, which is symmetrically installed under the upper workbench 1. Parallel longitudinal ball guide rails 18 are installed on the ball guide rails 18 as trolley plates 17 that move linearly. Die base, under the trolley plate 17, a rodless cylinder 20 that can make the mold base and the processed steel pipe 21 run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com