Machine tool

A technology for machine tools and components, applied in the field of machine tools, can solve problems such as adhesion to operators and leakage of coolant, and achieve the effects of easy maintenance, fewer parts, and fewer assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

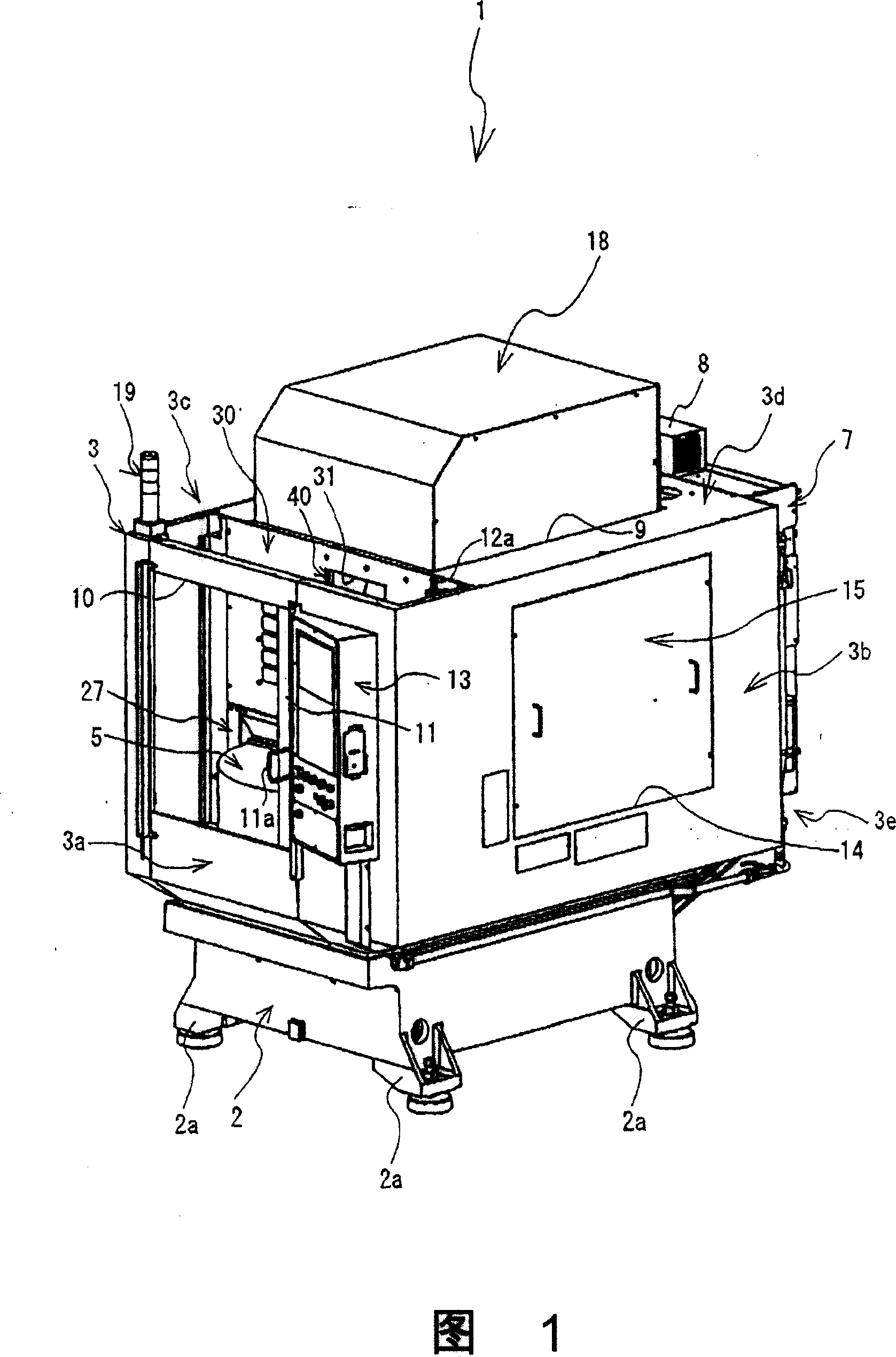

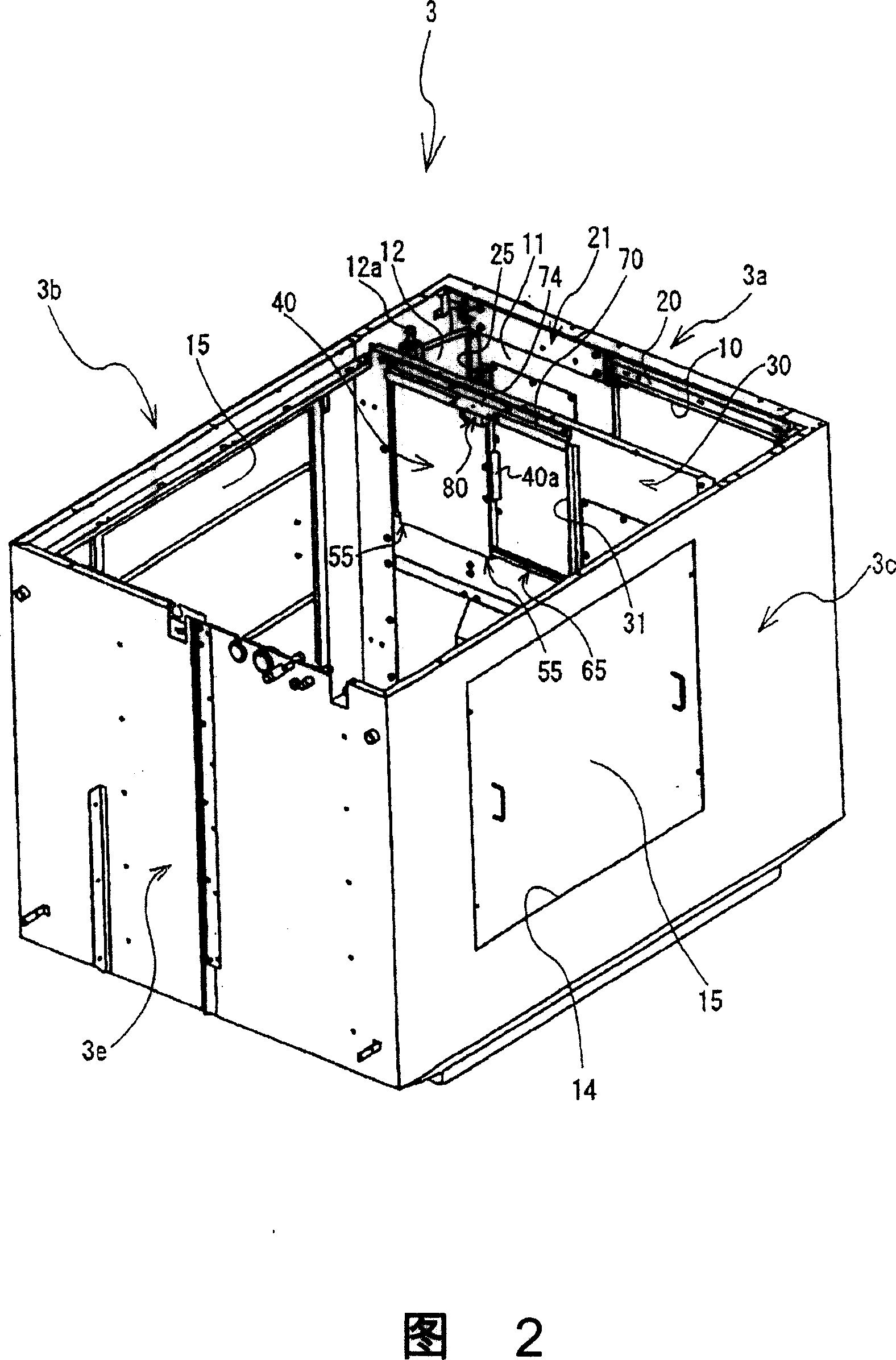

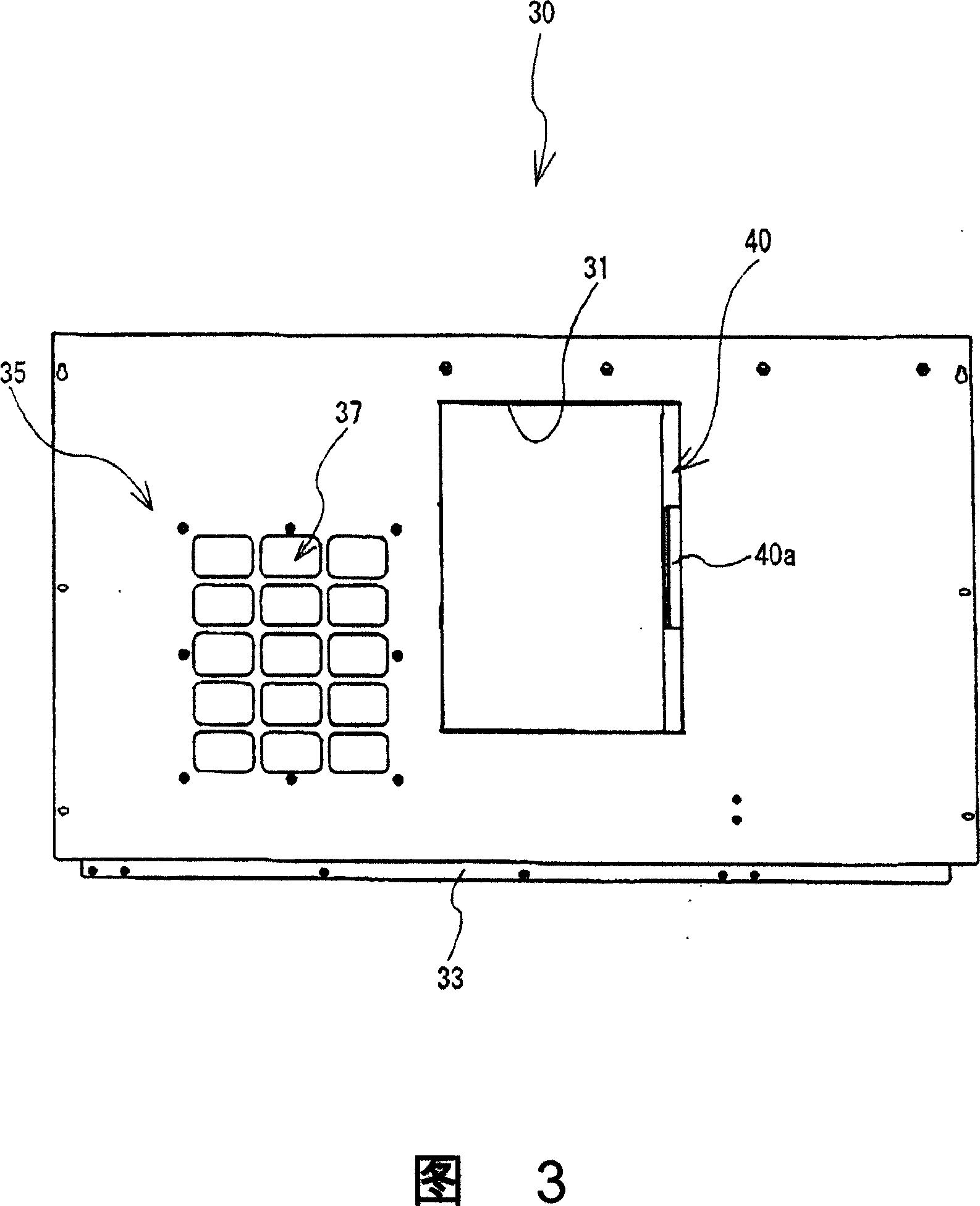

[0029] As shown in FIG. 1 , the machining center 1 of this embodiment has a partition 30 for partitioning the machining area inside the protective shutter 3 . The partition plate 30 is provided with a slide door 40 for opening and closing the opening 31 . The first feature of the present invention is that the number of parts can be reduced by simplifying the structure of the guide rail that guides the sliding door 40 . The second feature of the present invention is that by covering the guide rail structure with the guide rail cover plate 70 , it is possible to prevent chip powder scattered from the processing area from adhering to and accumulating in the guide rail structure.

[0030] Next, a schematic configuration of the machining center 1 will be described. The machining center 1 shown in FIG. 1 can implement the required machining (such as "boring", "milling", "drilling", "cutting", etc.) ) machine tools. The main body of the machining center 1 comprises: a base 2 made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com