Roller grinder trimming equipment

The technology of top roller and dresser is applied in the directions of grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., which can solve the problems of high labor intensity, poor labor conditions, affecting the accuracy of grinding wheels, etc. Achieve the effect of reducing labor intensity, ensuring accuracy requirements, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

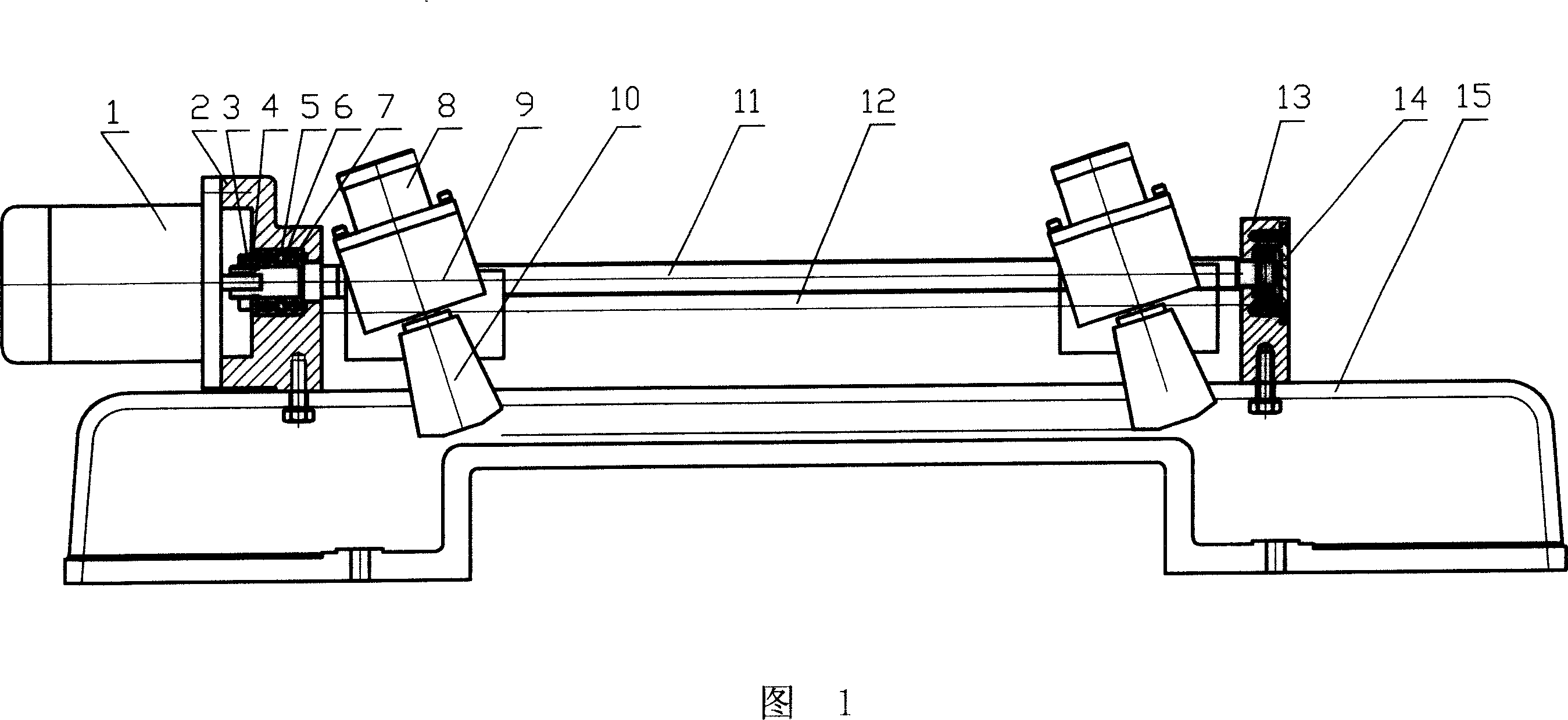

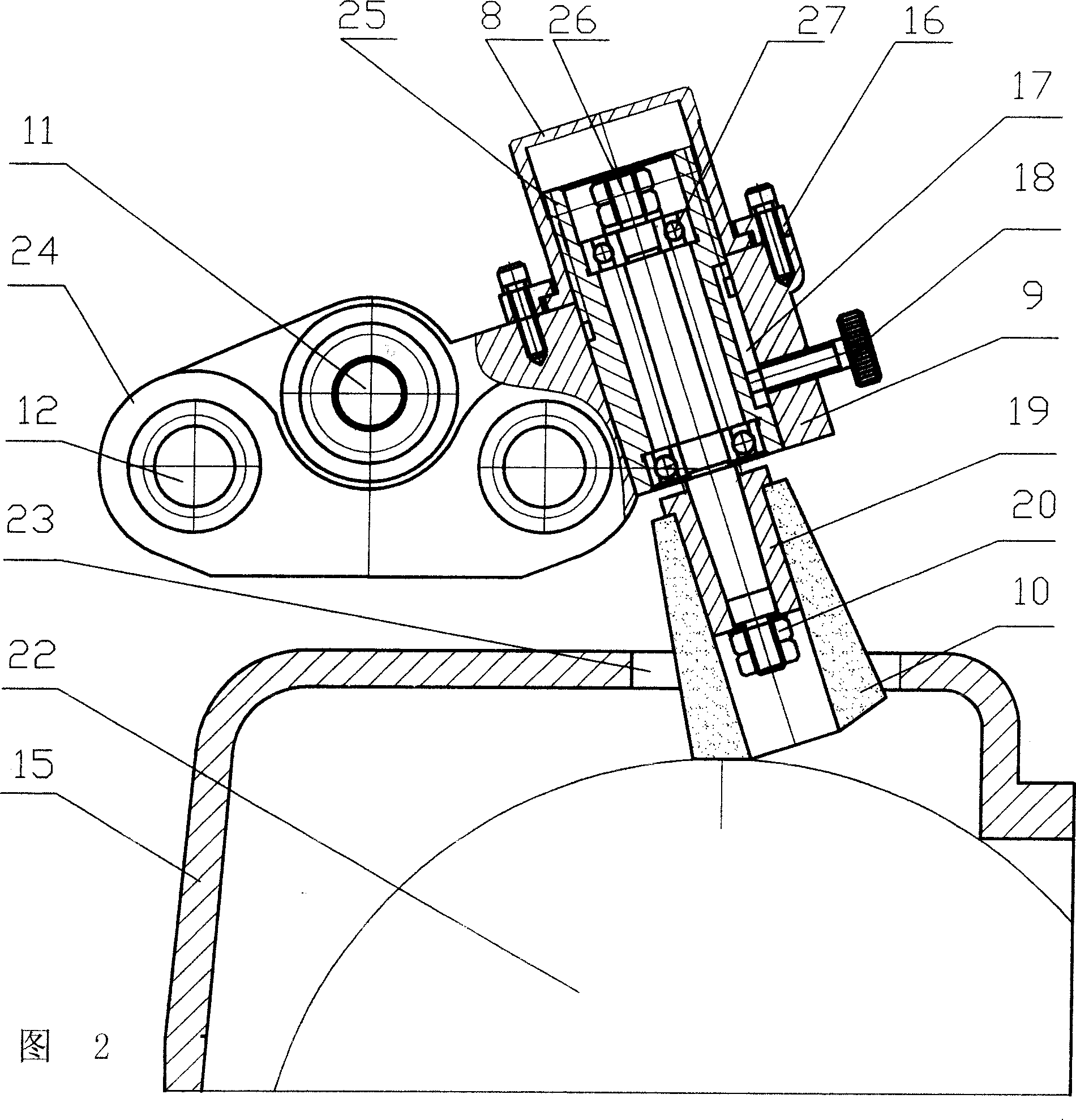

[0012] 1. Motor, 2. Support, 3. Nut, 4. Washer, 5. Outer lining, 6. Inner lining, 7. Bearing, 8. Scale cylinder, 9. Mounting sleeve, 10. Grinding wheel, 11. Wire Rod, 12, guide rod, 13, rear support, 14, end cover, 15, cover, 16, gland, 17, positioning groove, 18, locking bolt, 19, grinding wheel taper sleeve, 20, nut, 22, Top roller, 23, through hole, 24, sliding seat, 25, emery wheel frame cover, 26, emery wheel axle, 27, bearing.

[0013] As shown in the figure: between the support 2 and the rear support 13, the bearing 7 is used to install the screw rod 11 and the guide rod 12 parallel to each other, and the sliding seat 24 that can slide is installed on the screw rod 11 and the guide rod 12. 24, emery wheel 10 is installed. During work, the screw mandrel 11 is rotated to drive the sliding seat 24 to move on the screw mandrel 11 and the guide rod 12, and the sliding seat 24 drives the emery wheel 10 to move together, and the top roller 22 is ground.

[0014] An adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com