Control method of rotary compressor

A technology of rotary compressor, control method, applied in the direction of rotary piston machine, rotary piston pump, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., which can solve the efficiency problem, which is difficult to carry out smoothly, Problems such as wasting time and energy to achieve the effect of preventing inefficiency, preventing vibration, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

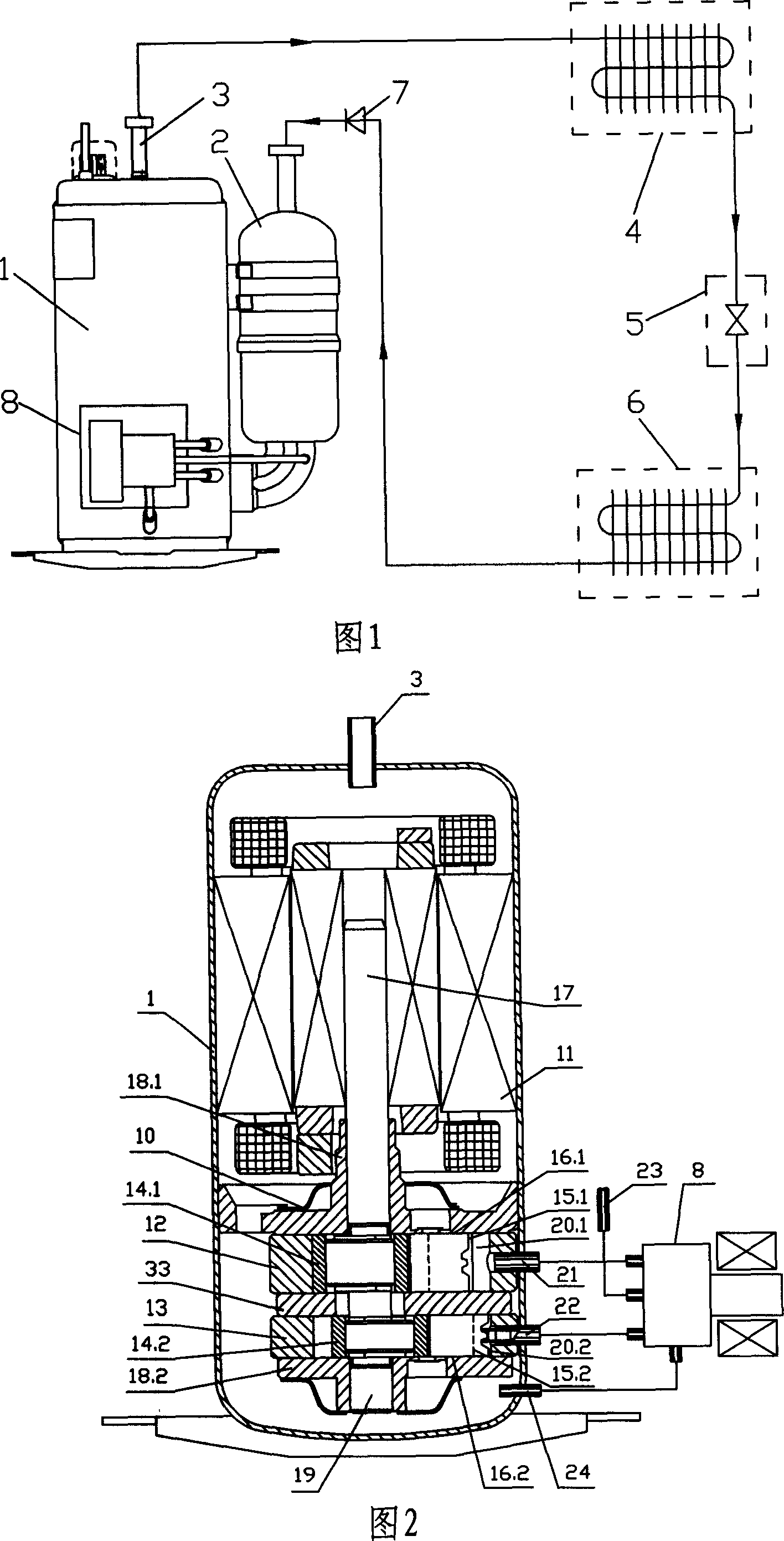

[0022] In the figure, 1 is compressor, 2 is liquid receiver, 3 is exhaust pipe, 4 is condenser, 5 is automatic expansion valve, 6 is evaporator, 7 is one-way valve, 8 is valve device, 10 is compression Assembly, 11 is the motor assembly, 12 is the first cylinder, 13 is the second cylinder, 14.1 is the first piston, 14.2 is the second piston, 15.1 is the first slide groove, 15.2 is the second slide groove, 16.1 is the first One slide, 16.2 is the second slide, 17 is the main shaft of the eccentric crankshaft, 18.1 is the upper bearing, 18.2 is the lower bearing, 19 is the sub-shaft of the eccentric crankshaft, 20.1 is the first slide chamber, 20.2 is the second slide chamber, 21 is a first pressure switching tube, 22 is a second pressure switching tube, 23 is a low pressure tube, 24 is a high pressure tube, and 33 is an intermediate partition.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com