Turning flow type methane biological oxidation apparatus

A bio-oxidation and methane technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical equipment and methods, etc. Restrictions and other issues to achieve the effect of reducing global warming potential, prolonging residence time, and significant global environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

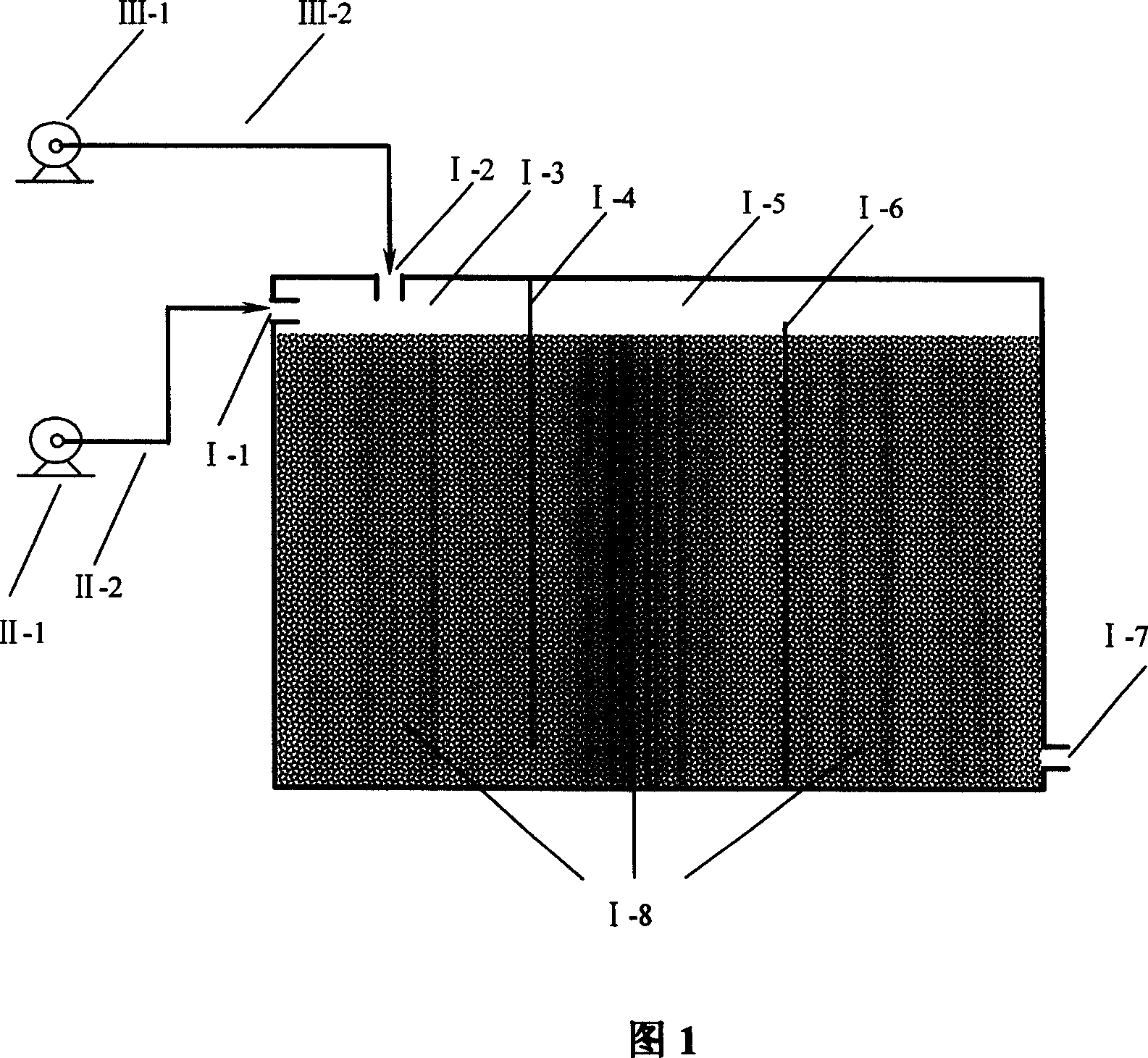

[0015] Fig. 1 shows the schematic structure of the present invention. It can be seen from Figure 1 that the turning flow methane biooxidation device includes: a reactor, a methane supply system and an air supply system. Specifically, the reactor consists of a methane inlet I-1, an air inlet I-2, a gas mixing chamber I-3, an upper baffle I-4, a gas mixing chamber I-5, and a lower baffle I. -6, exhaust port I-7 and filling medium I-8. Filling medium I-8 is natural sandy soil containing methane-oxidizing bacteria and pores. The methane supply system consists of blower II-1 and gas pipeline II-2. The air supply system consists of fan III-1 and air pipe III-2.

[0016] The course of work of the device of the present invention is:

[0017] (1) Methane is forced into the gas mixing chamber I-3 through the methane inlet I-1 at the top of the reactor through the fan II-1 and the gas delivery pipe II-2; the air passes through the fan III-1 and the gas delivery pipe III-2, The air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com