Large span prestressed beam using bonded and non-bonded hybrid reinforcement design method

A technology of prestressed beams and mixed reinforcement, applied in the directions of girders, joists, trusses, etc., can solve problems such as reducing the prestressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1: Using the mixed reinforcement method of the present invention with bonded and unbonded prestressed tendons

[0091] 1. Determine the cross-sectional size of the prestressed beam

[0092] According to the height-span ratio and load conditions, take h l = 1 12 , b h = 2.5 (where l=12000mm ),

[0093] Determine the cross-sectional size of the beam as: b×h=400×1000mm

[0094] 2. Layout selection and area estimation of prestressed tendons

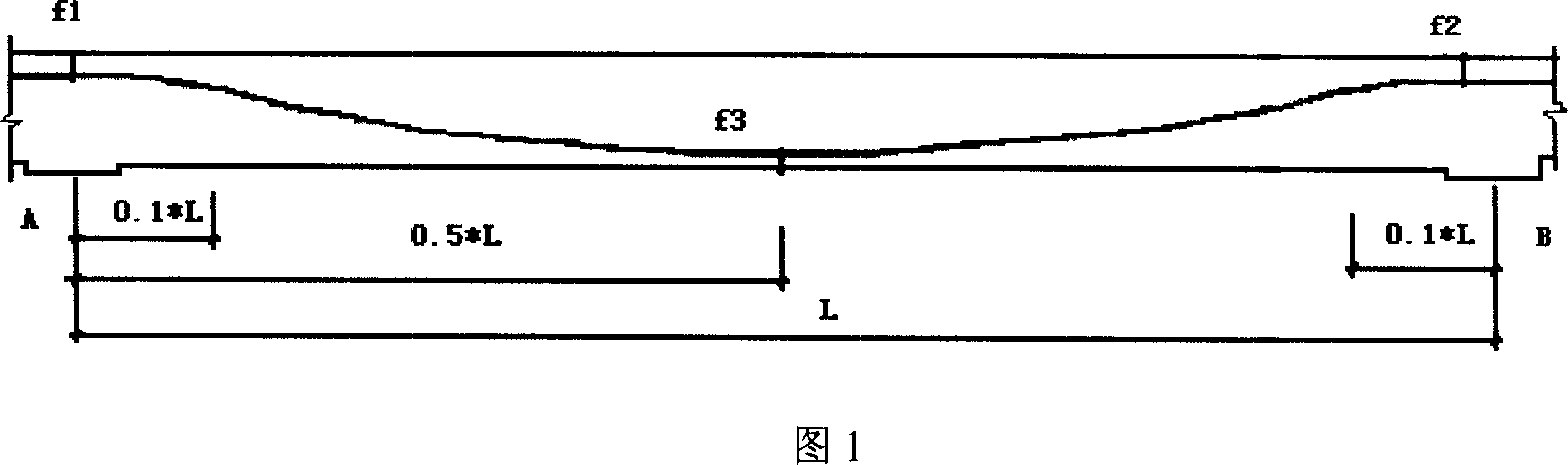

[0095] According to the specific situation of the beam section form, and considering its use function and requirements, the 1860-grade steel strand is selected as the reinforcement material. Concrete adopts C40 grade. Three sections of parabola are preliminarily selected for the line type, as shown in Figure 1, the distances f1, f2, and f3 of the prestres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com