Laser resonance cavity of high-power and large-energy low-rank mode output

A laser resonator, high-energy technology, applied in the field of lasers, can solve the problems that the laser resonator cannot achieve low-order mode output, laser beam mode distortion, etc., and achieve the effect of improving the application range and realizing low-order mode output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

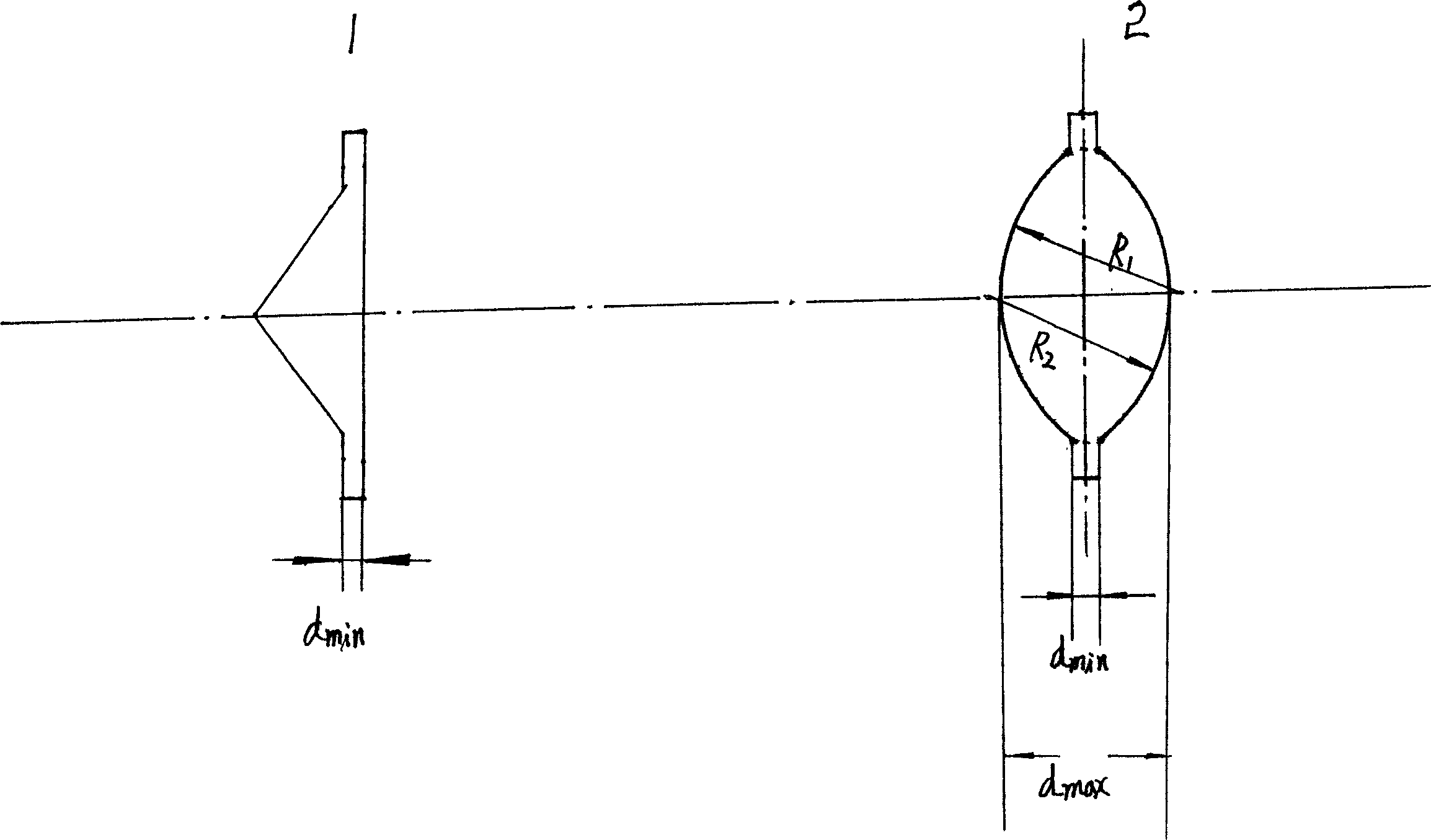

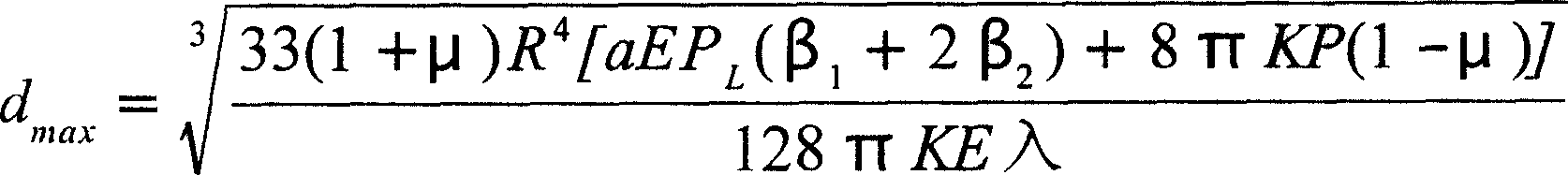

[0011] A laser resonator with high-power, high-energy and low-order mode output is characterized in that it is composed of a directional prism (1) and a symmetrical biconvex mirror (2), the directional prism (1) is a total reflection mirror, and the symmetrical biconvex mirror (2) is the output mirror.

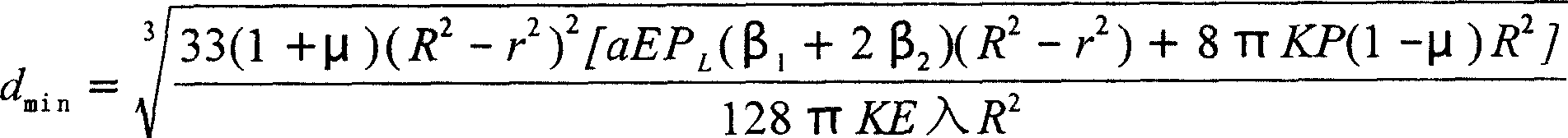

[0012] The resonant cavity is designed according to the theoretical formula, which is characterized in that within the working range of the resonant cavity, the thermal deformation of the cavity mirror is basically less than λ / 10, the laser beam does not undergo mode distortion, and low-order mode output is realized in high-power and high-energy applications.

[0013]

[0014] Where a——material linear expansion coefficient μ——material Poisson’s ratio

[0015] E——Young’s modulus of the material K——The thermal conductivity of the material

[0016] beta 1 ——absorption coefficient of substrate material β 2 ——Coating absorption coefficient

[0017] P L ——Laser output po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com