Method of manufacturing vibration plate for speaker and vibration plate for speaker

A manufacturing method and technology of vibration plates, which are applied in the manufacture of vibration plates for loudspeakers and the field of vibration plates for loudspeakers, can solve problems such as delamination between layers, decline in sound characteristics of loudspeakers, and long-term

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

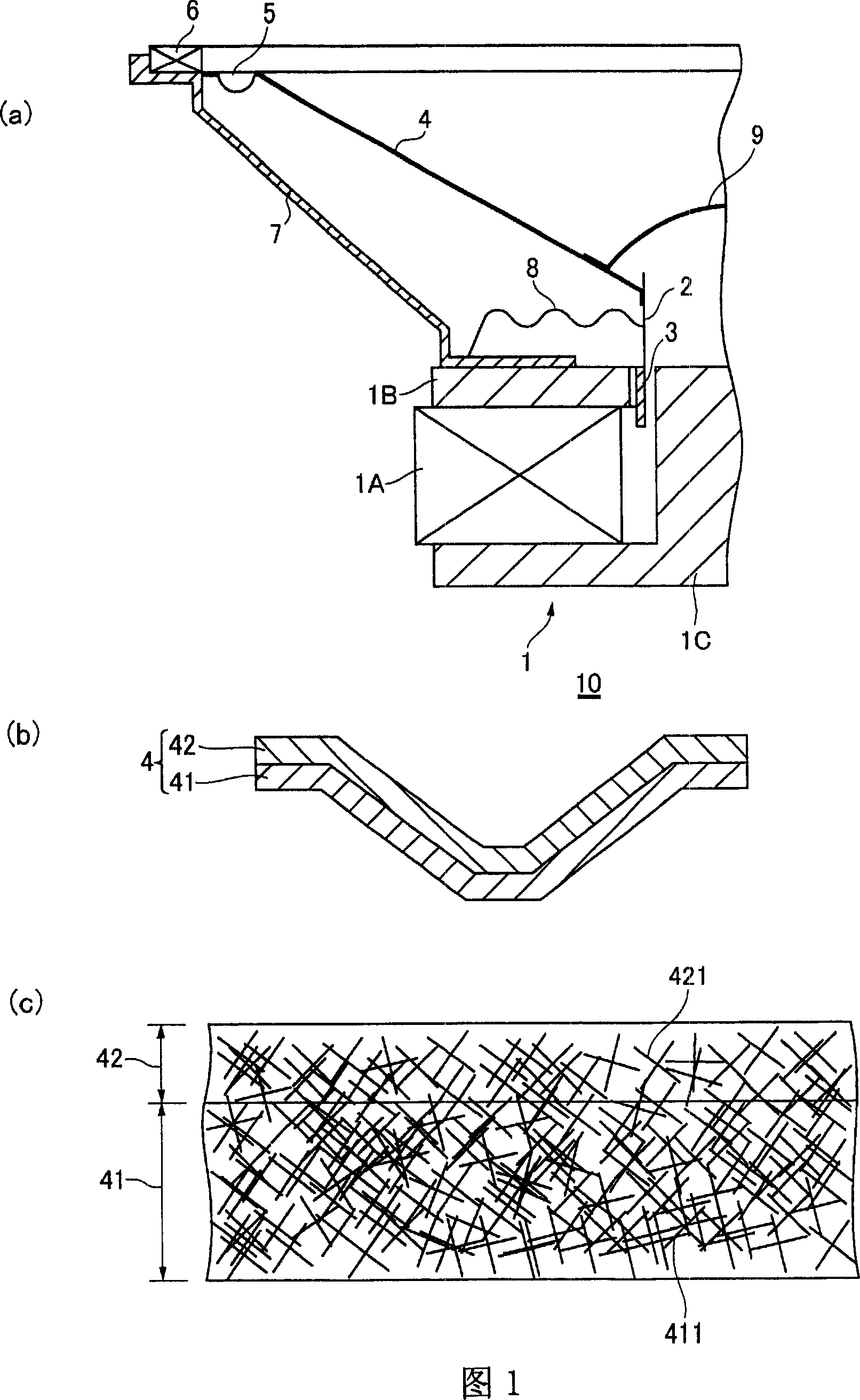

[0062] FIG. 1 is a diagram illustrating a speaker diaphragm according to a first embodiment of the present invention. FIG. 1( a ) is a half-sectional view illustrating a speaker device using a speaker diaphragm according to a first embodiment of the present invention. FIG. 1( b ) is a cross-sectional view for explaining the speaker diaphragm shown in FIG. 1( a ). FIG. 1( c ) is an enlarged cross-sectional view for explaining the speaker diaphragm shown in FIG. 1( b ).

[0063] As shown in FIG. 1( a), a speaker device 10 using a speaker diaphragm according to the first embodiment of the present invention has: a magnetic circuit 1 formed by a magnet 1A, a plate 1B, and a yoke 1C; a voice coil 3 configured In the magnetic gap of the magnetic circuit 1, and wound on the voice coil bobbin 2; The outer peripheral edge of the speaker diaphragm 4 is fixed to the speaker frame 7 via the edge portion 5 and the gasket 6 . Voice coil bobbin 2 is fixed to speaker frame 7 via damping mem...

no. 2 approach

[0101] FIG. 10 is a diagram for explaining a method of manufacturing the speaker diaphragm 4b according to the second embodiment of the present invention. Descriptions of the same configuration, operation, and the like as those of the first embodiment are omitted.

[0102] The manufacturing method of the speaker diaphragm 4b of the present embodiment is to manufacture the speaker diaphragm 4b by forming it by a drying method after papermaking. Specifically, as shown in FIG. 10, for example, in the drying chamber 600, the first vibration plate layer 41b and the second vibration plate layer 42b stacked by the papermaking described above are arranged on a mold 63 having a hollow portion 631, and are While being sucked by a vacuum pump 632 , it is dried by a heating device 64 such as a gas furnace arranged above the mold 63 . In this embodiment, the diaphragm 4b for speakers is produced by drying only without pressurization.

[0103] Next, a specific method of manufacturing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com