Subvacuum high speed train system

A technology for high-speed trains and operating systems, applied in tunnel systems, roads, tracks, etc., can solve problems such as traffic accidents between trains and pedestrians or other means of transportation, impact on residents' life and normal rest, and large environmental pollution, etc., to reduce traction power and energy consumption, reduce train traffic accidents, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

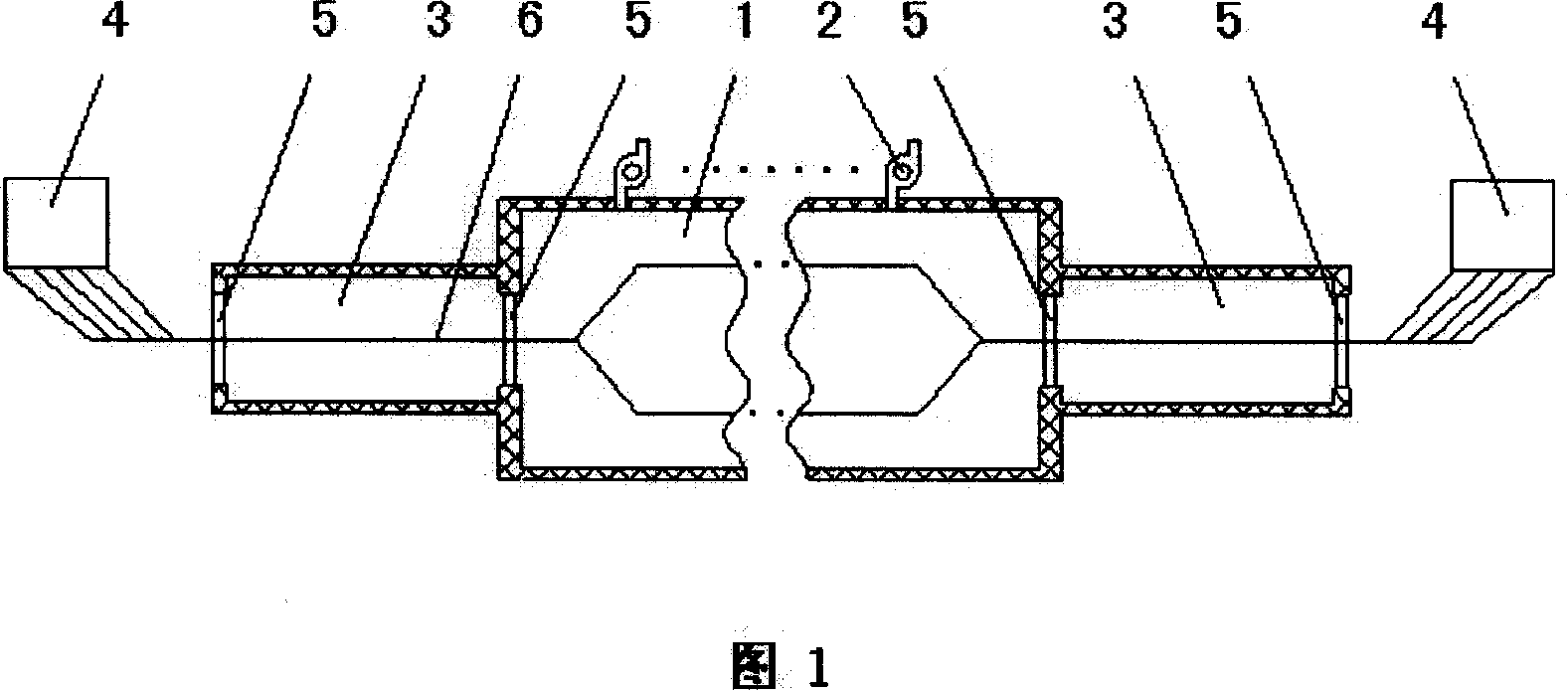

[0012] Example. As shown in Figure 1, a sub-vacuum high-speed train operating system, the system is to set up a closed tunnel on the running path between the station and the station, and maintain a sub-vacuum state below 10Kpa in the closed tunnel to reduce the stress in the train operation. Air resistance, reducing the power required for the train to overcome air resistance, and the impact of noise during train operation on the outside world. There are car covers at both ends of the closed tunnel. When the train leaves the station, first open the pressure-holding door between the station and the car cover. The train enters the car cover from the station, then closes the pressure-preserving door between the station and the car cover, and then opens The pressure-holding door between the car cover and the closed tunnel, the train enters the closed tunnel; when the train enters the station, it is contrary to the above process, and its purpose is to prevent the vacuum degree in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com