Piezoelectric equipment with amplifying device

A technology of piezoelectric devices and piezoelectric materials, applied in the direction of piezoelectric devices/electrostrictive devices, etc., can solve problems such as reduced reliability performance, sensitive performance of inherent curvature devices, and equipment installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Different embodiments of the piezoelectric device according to the present invention are described below with reference to the accompanying drawings, however, the present invention is not limited to these embodiments described in the accompanying drawings.

[0023] In the following description, the term "piezoelectric material" refers to those materials that can change their shape according to an electric signal and can generate an electric signal according to an applied load. These piezoelectric materials are preferably but not limited to piezoelectric ceramics, such as lead zirconate titanate (PZT), barium titanate (BaTiO 3 ), lead magnesium niobate-lead titanate (PMN-PT), and lead zirconium niobate-lead titanate (PZN-PT).

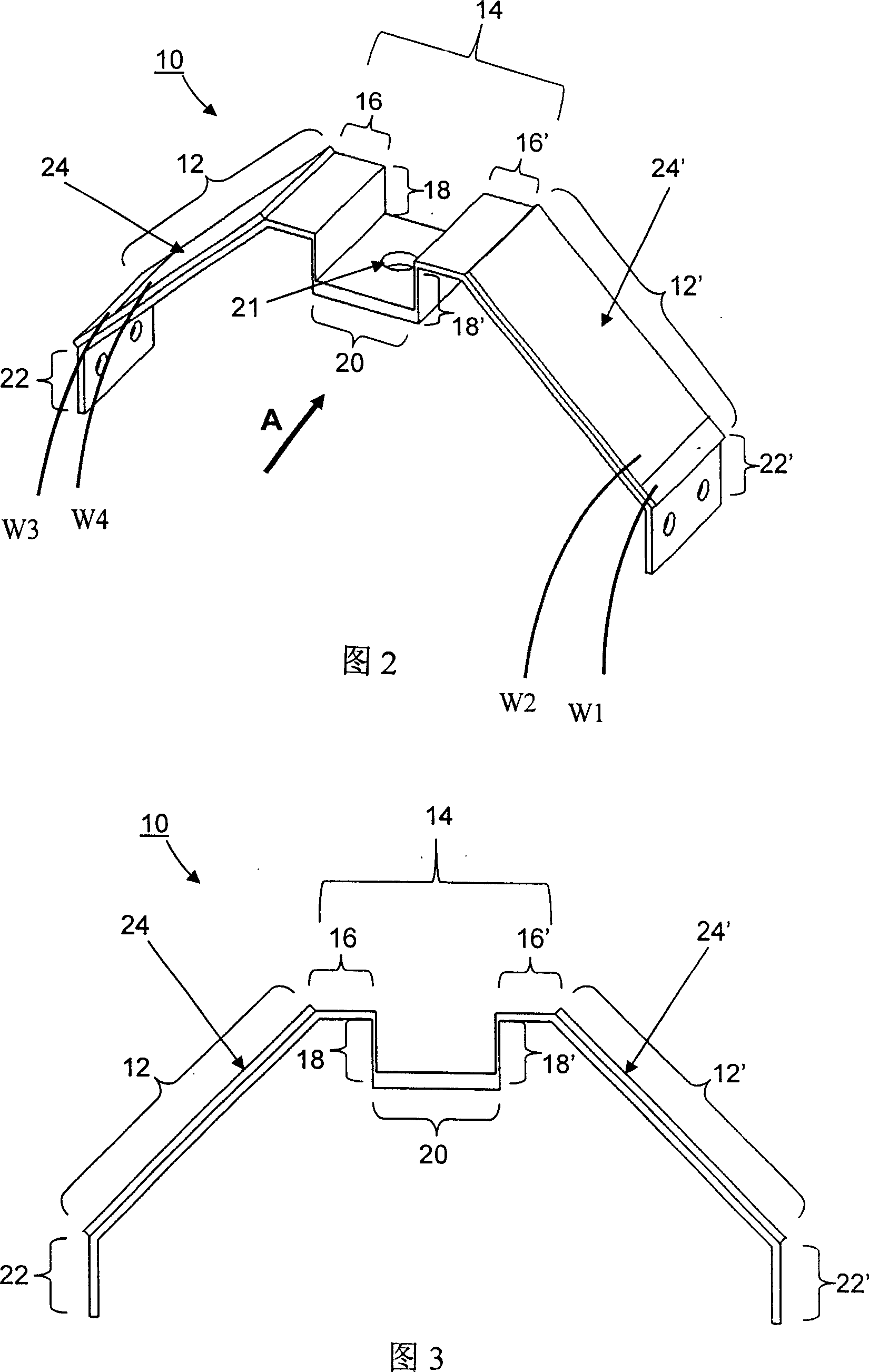

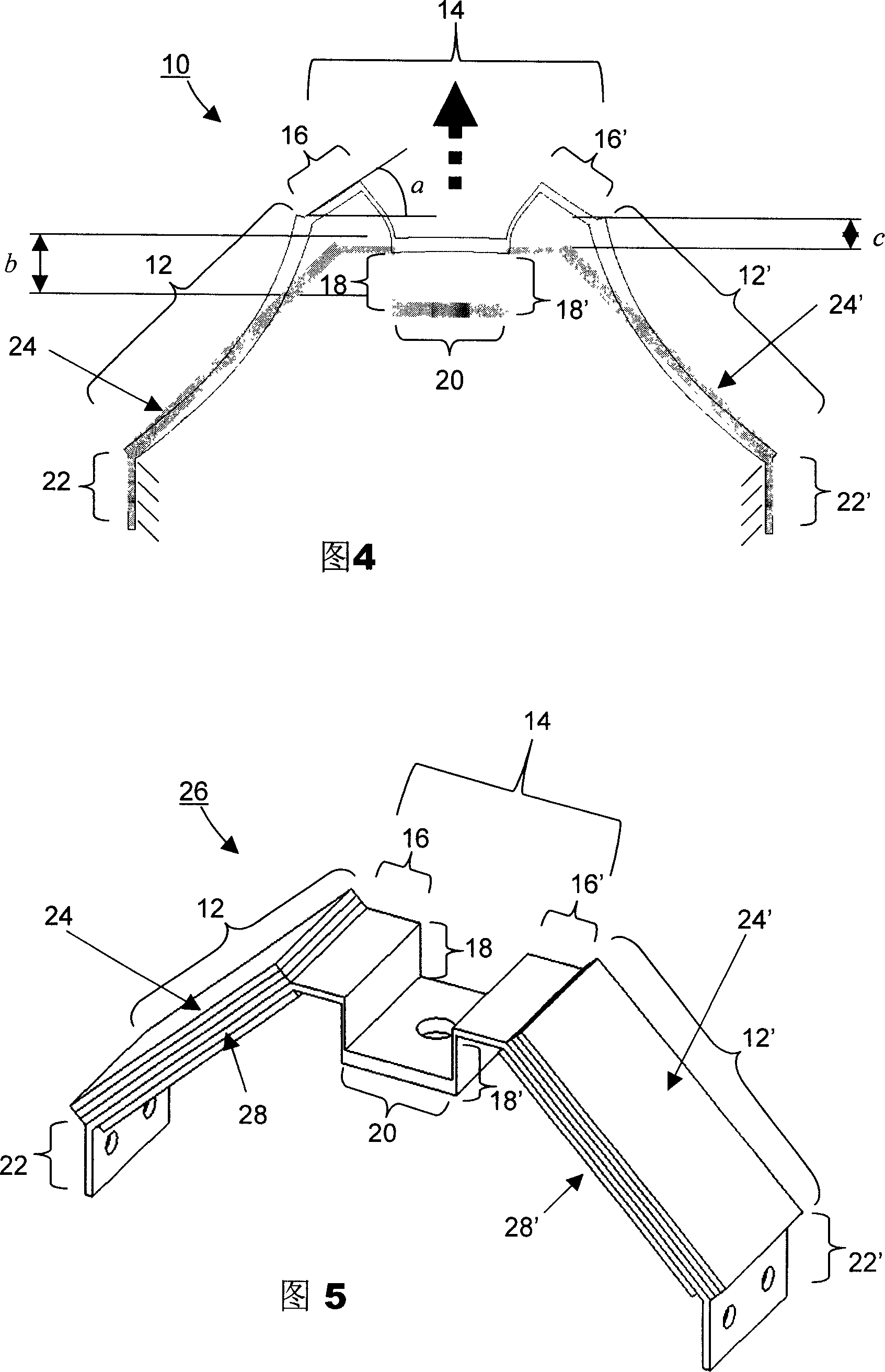

[0024] FIG. 2 is a schematic perspective view of the piezoelectric device 10 according to the first embodiment of the present invention. The piezoelectric device 10 has a saddle-like mechanical amplifier structure 14, and its driving part include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com