Surface polishing-finishing processing method based on fluid-field restriction type hydraulic grinding-particle flow

A finishing and abrasive flow technology, applied in the field of structured surface finishing of mechanical parts, can solve the problems of inability to deal with small-sized and special-structured surfaces, and achieve good environmental protection, high processing efficiency, and good texture in the processing environment. Effects of randomness and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

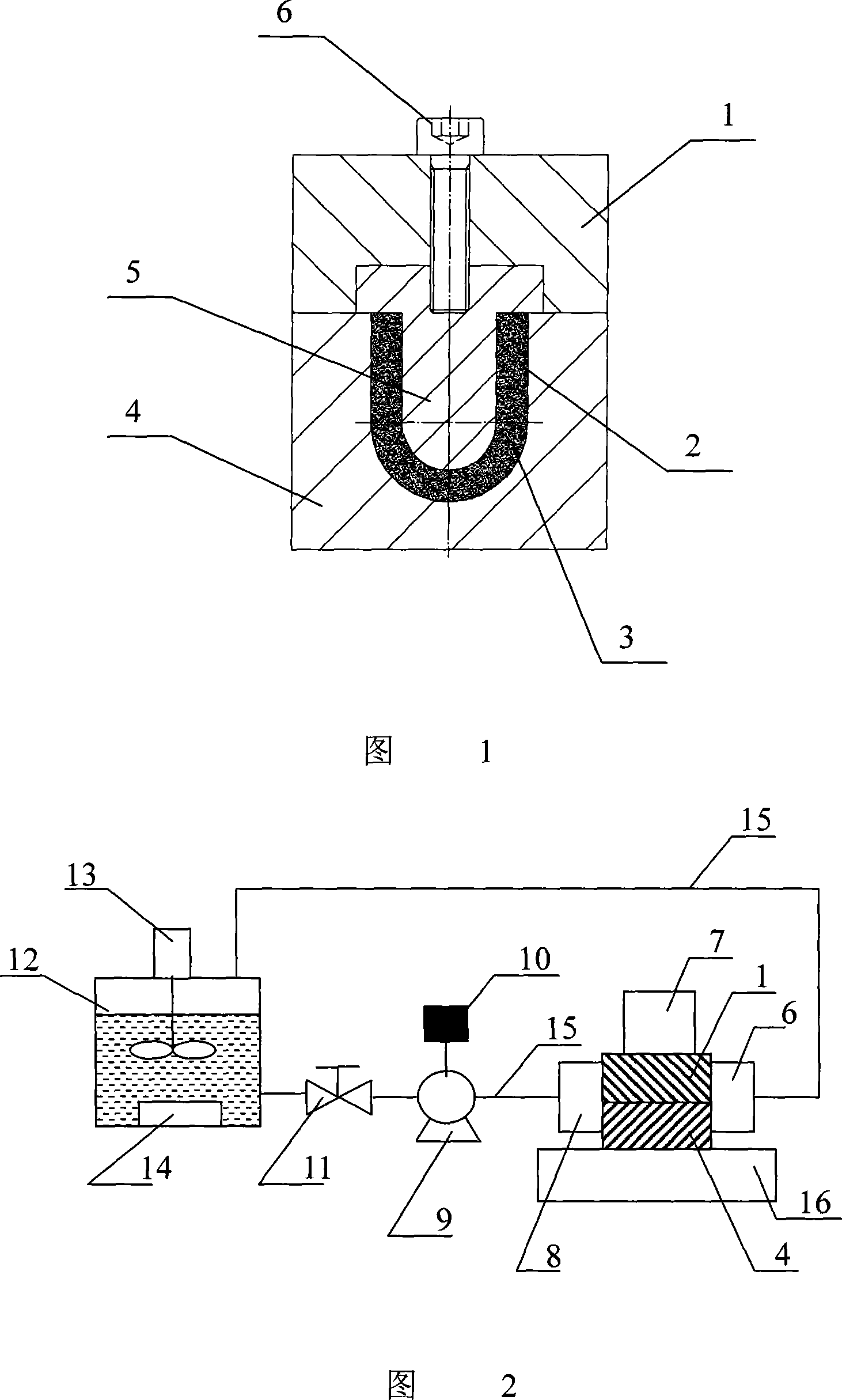

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Referring to Fig. 1 and Fig. 2, a surface finishing method based on flow field constrained hydrodynamic abrasive flow mainly includes the following steps:

[0023] a. On the structured surface 2 of the processed workpiece 4, the constrained module 5 is arranged through the fixture, and the constrained module 5 and the structured surface 2 of the processed workpiece 4 constitute the flow channel 3 of the liquid-solid two-phase abrasive flow;

[0024] b. Connect the flow channel 3 with the abrasive particle flow circulation system;

[0025] c. Start the abrasive particle flow circulation system. Under the constraint of the shape of the flow channel 3, a flow field-constrained hydraulic abrasive flow of high-speed circulating flow is formed in the flow channel 3 to impact the structured surface 2 of the workpiece 4. Erosion micromachining.

[0026] In the above a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com