(NH4+)XMOS2 intercalation compound and its preparing method

A compound, single-layer molybdenum disulfide technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, can solve storage stability problems and other problems, and achieve good storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by non-limiting embodiment:

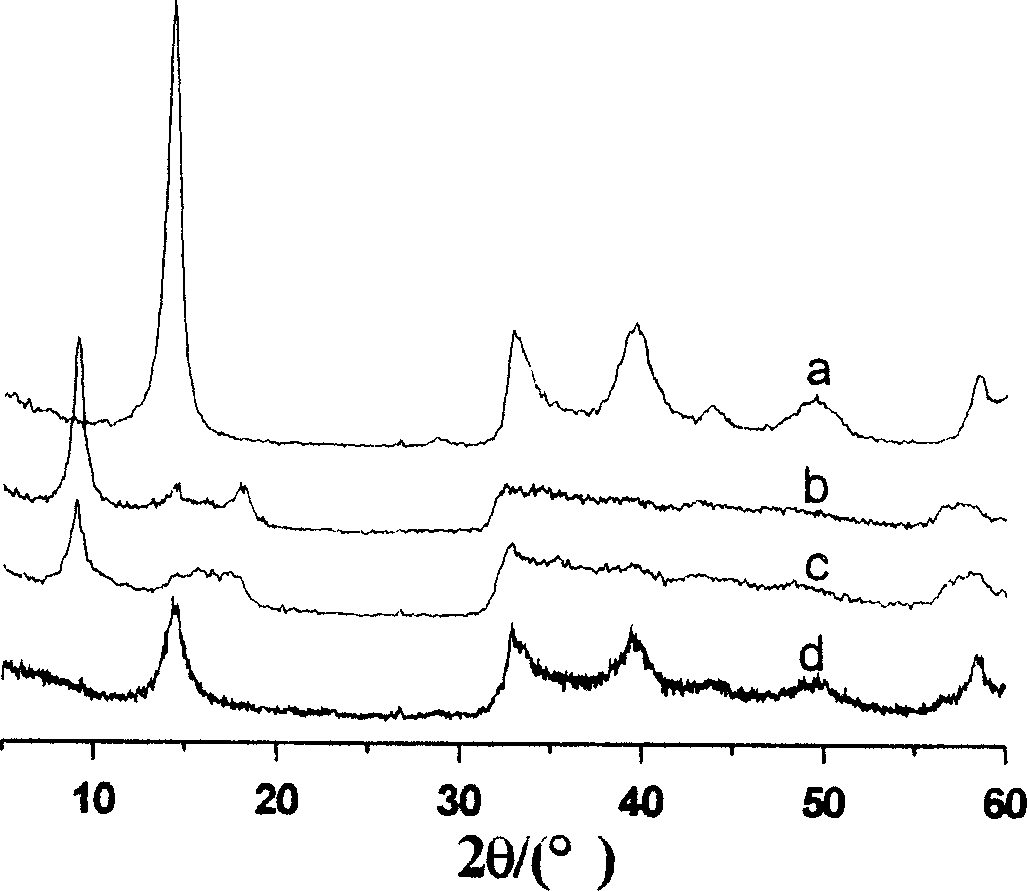

[0018] 1. In the pass N 2 Under gas conditions, 20 parts by volume of 0.5mol / L n-butyllithium n-hexane solution and 1.6 parts by mass of molybdenum disulfide were stirred and reacted in a three-necked flask for 48 hours. 30 parts by volume of distilled water, and ultrasonically oscillated for 1 hour to obtain a single-layer molybdenum disulfide suspension, measure 50 parts by volume of the single-layer molybdenum disulfide suspension, and mix 30 parts by volume of ammonium chloride solution with a mass concentration of 20% under the condition of stirring Add it into the suspension under low temperature, stir and react at room temperature for 6 hours, filter after standing, wash with water, and dry in vacuum at 60°C for 24 hours to obtain (NH 4 + ) 2.9 MoS 2 intercalation compound.

[0019] 2. In the pass N 2 Under gas conditions, 100 parts by volume of 8.6mol / L n-butyllithium n-hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com