Underground preburied column high-precision smart verticality-regulating system and mounting construction method

A high-precision, vertical column technology, applied in the field of vertical adjustment system, can solve the problems of limited airbag adjustment range, increased construction workload, unfavorable support column vertical adjustment, etc., to achieve reasonable adjustment of construction work area, full use of space, and convenient vertical adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below in conjunction with accompanying drawing.

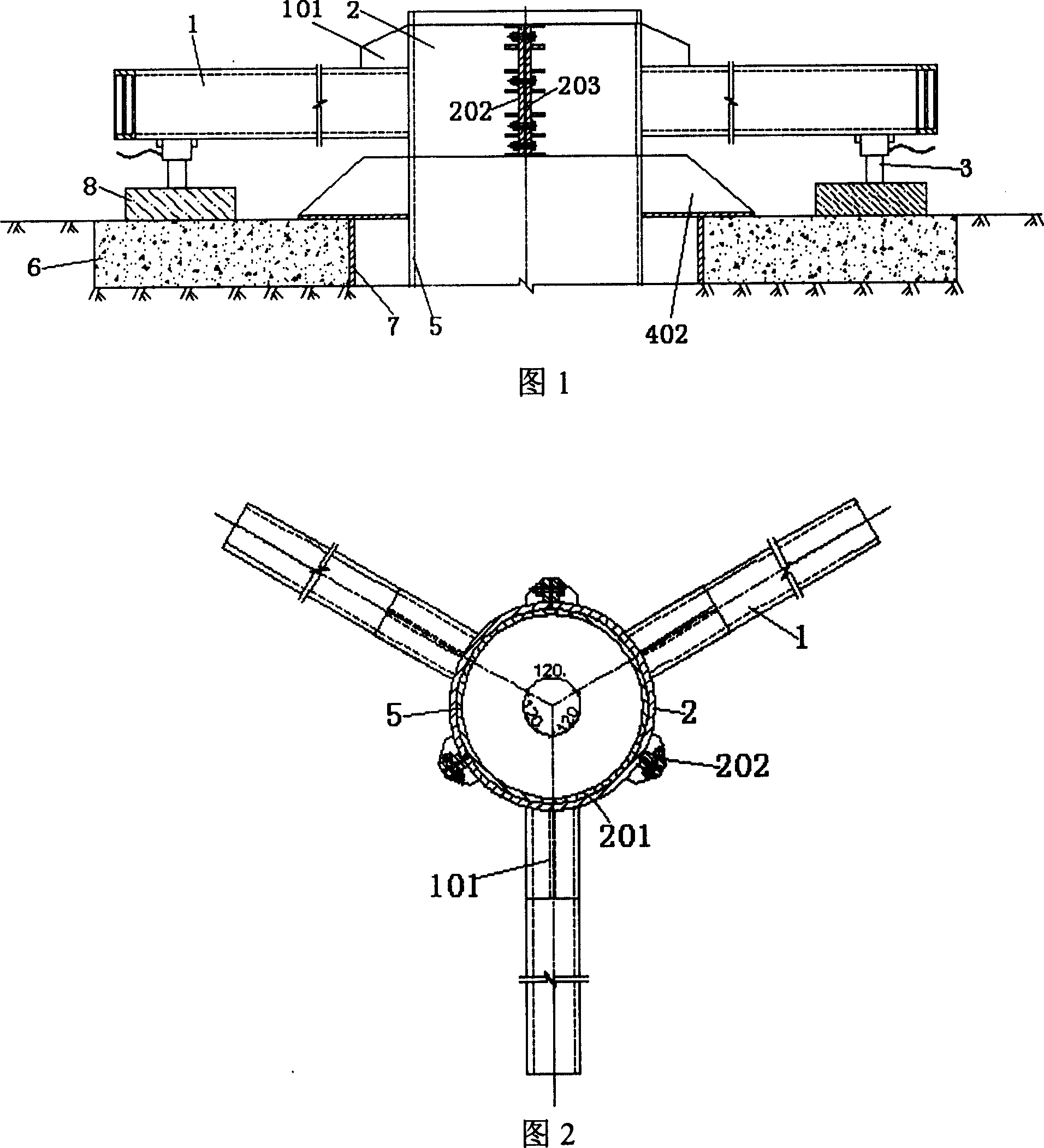

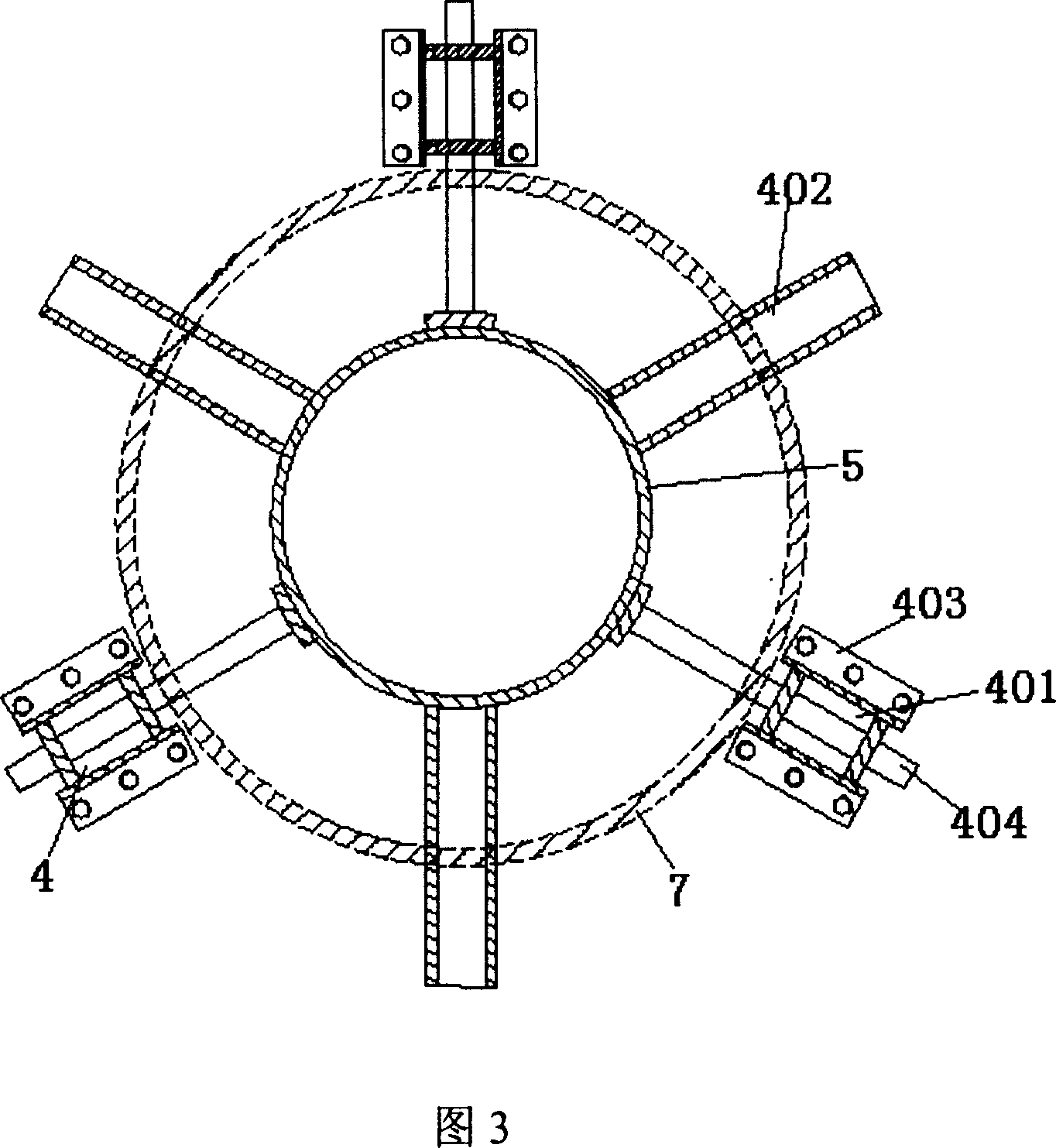

[0024] Referring to Fig. 1, the high-precision intelligent vertical adjustment system for underground pre-embedded columns of the present invention includes a vertical adjustment system and a control system, and the vertical adjustment system includes a force arm beam 1, a positioning sleeve 2, a hydraulic device 3 and an initial positioning device 4 (as shown in Figure 3); one end of the arm beam 1 is connected to the embedded column 5 through the positioning sleeve 2, and the hydraulic device 3 is supported on the end of the arm beam away from the embedded column as the force source of the vertical adjustment system The lower part; the initial positioning device 4 is fixedly connected with the embedded component;

[0025] The control system includes an inclinometer, a computer and a control module, and the inclinometer is used to monitor the inclination of the embedded column in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com