Wire bonding method and apparatus

A wire bonding and bonding technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, non-electric welding equipment, etc., can solve problems such as increased idle time, limited accuracy, and PR positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

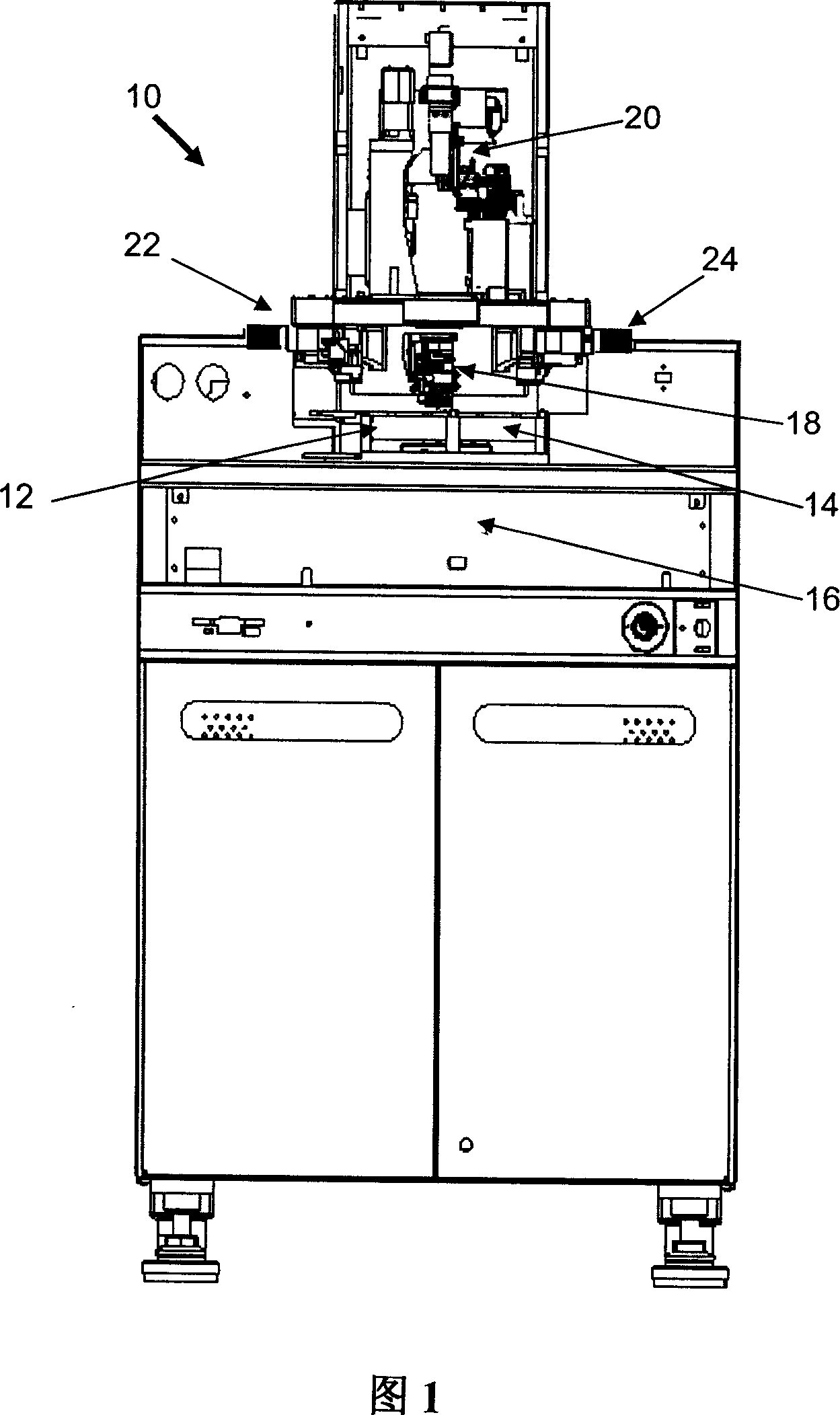

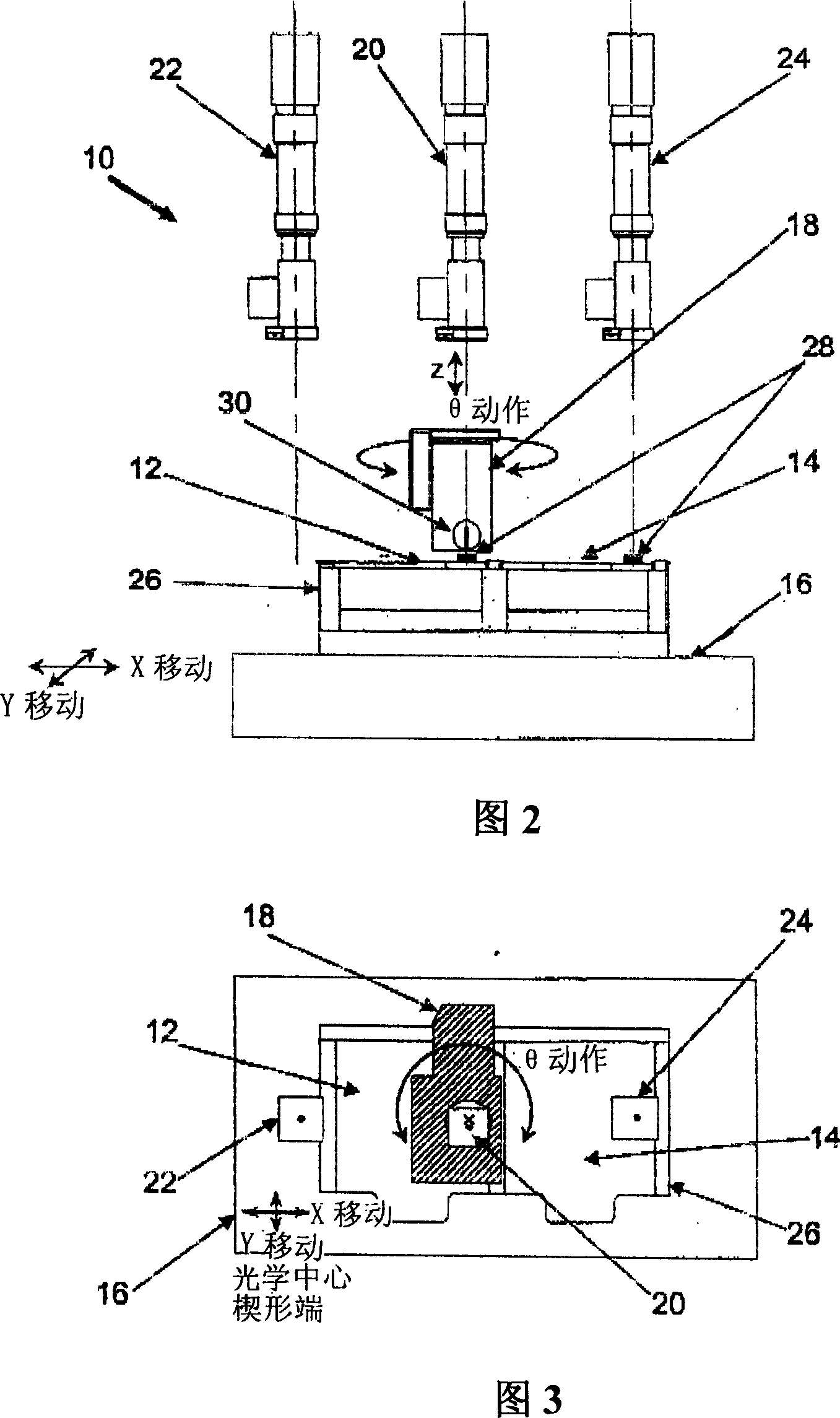

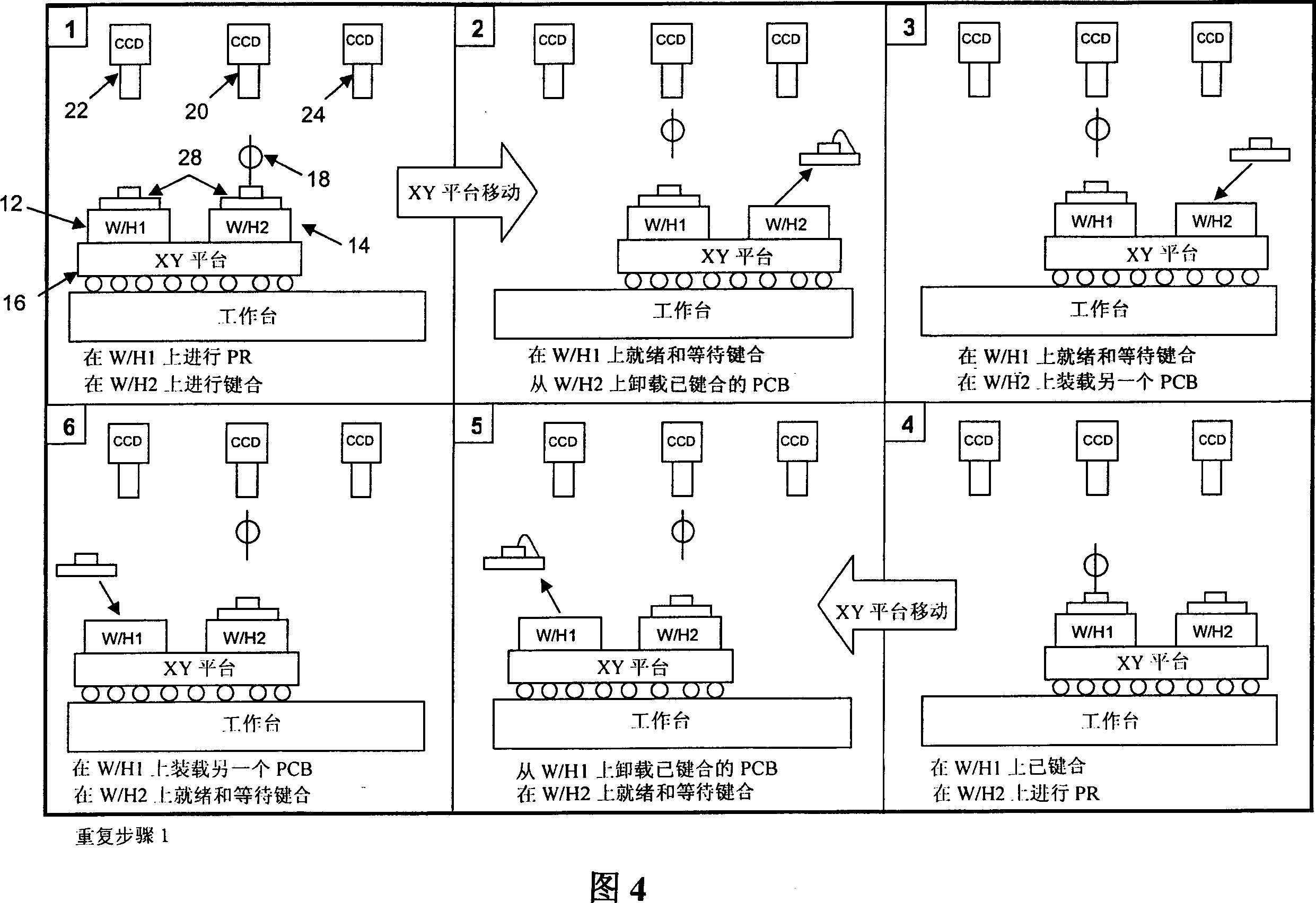

[0020] FIG. 1 is a schematic side view of a wire bonding machine 10 according to a preferred embodiment of the present invention. It generally includes: a double carrier, composed of a left carrier 12 and a right carrier 14; a positioning platform such as an XY platform, used to control the position of the double carriers 12, 14; a bonding head 18, used to complete wire bonding. The dual carrier 12 , 14 is mounted on an XY stage 16 .

[0021] There is also a first optical system such as left optical system 22 , a second optical system such as right optical system 24 and a third optical system such as central optical system 20 . These optical systems 20, 22, 24 preferably have built-in autofocus capability and adjustable magnification. The central optical system 20 is generally used to observe the bonding point and monitor the quality of the bonding wire before bonding, while the left optical system 22 and the right optical system 24 are set and arranged to observe the bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com