Switchable tappet

A technology of switches and cup-shaped tappets, which is applied to valve devices, machines/engines, mechanical equipment, etc., can solve problems such as complex structures of methods and methods, increased manufacturing costs, and unavailability, and achieves the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

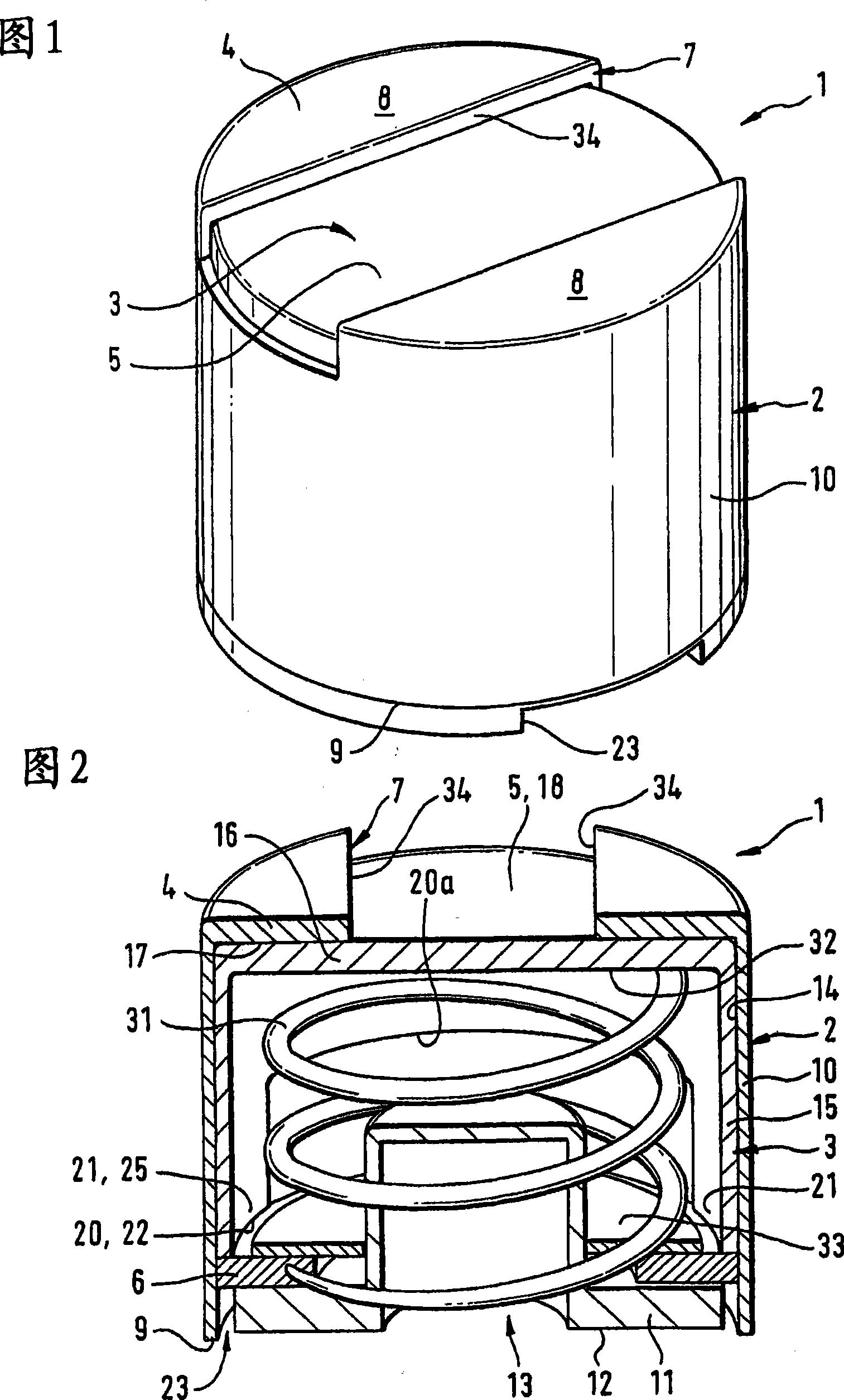

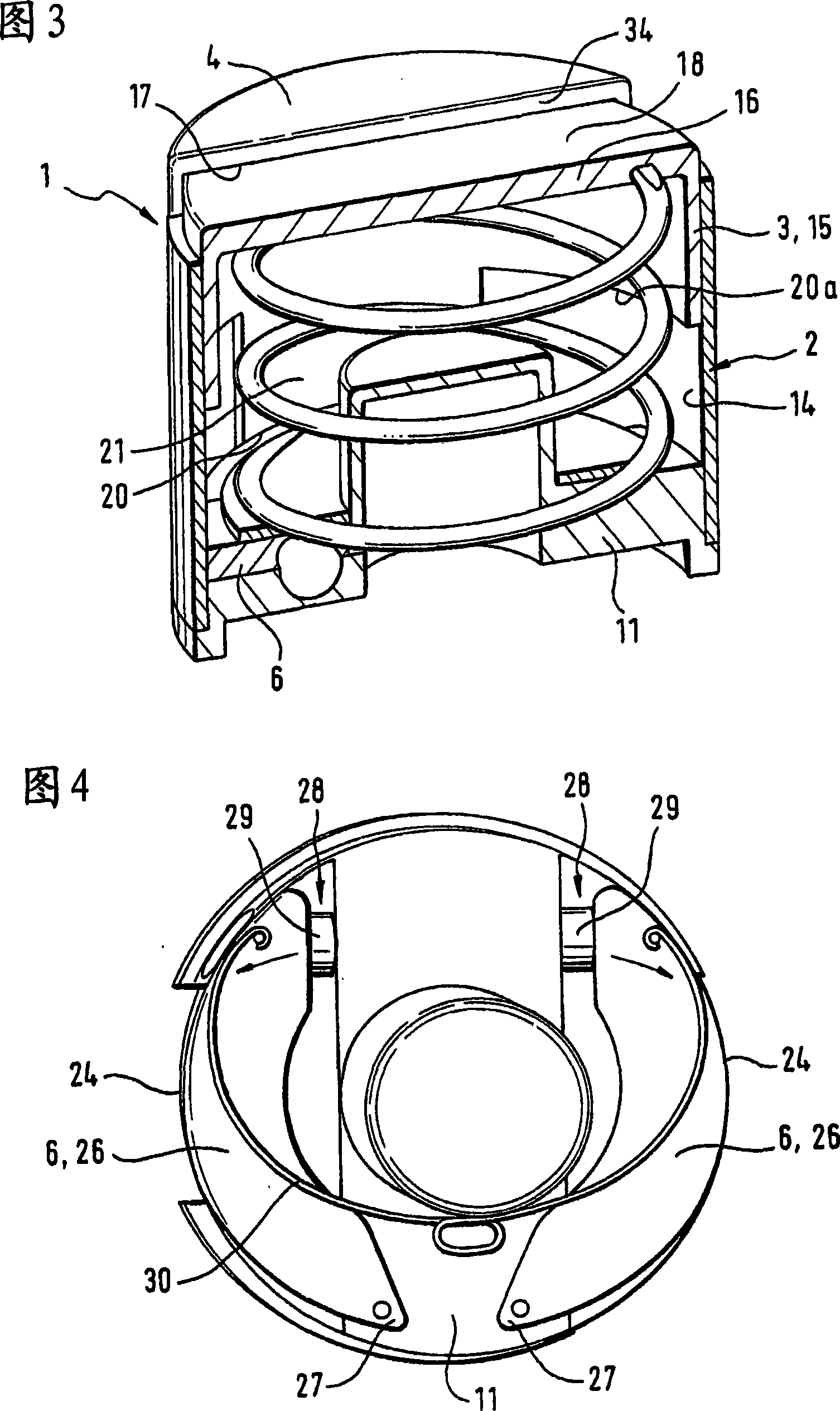

[0031] 1 to 3 show a switchable tappet 1 . The tappet comprises a hollow cylindrical outer housing 2 , which is plugged telescopically and axially displaceably with a cup-shaped inner housing 3 .

[0032] The bottom 4 of the outer housing 2 has a recess 7 which runs through completely diametrically, viewed in the direction of cam movement. Thus, for cam activation, the sector 8 remains on both sides of the recess 7 . The bottom 5 of the inner housing 3 is designed to be closed and rests against the underside 17 of the bottom 4 of the outer housing 2 in the coupled state.

[0033] The bottom part 18 of the inner housing 3 protruding into the recess 7 of the outer housing 2 serves as actuating high-lift cam. In contrast, the sector 8 of the bottom 4 of the outer housing 2 serves here as an actuating low-lift cam.

[0034] As a result, the base 5 of the inner housing 3 extends completely over the entire diameter of the tappet, and there is a large sliding surface for cams with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com