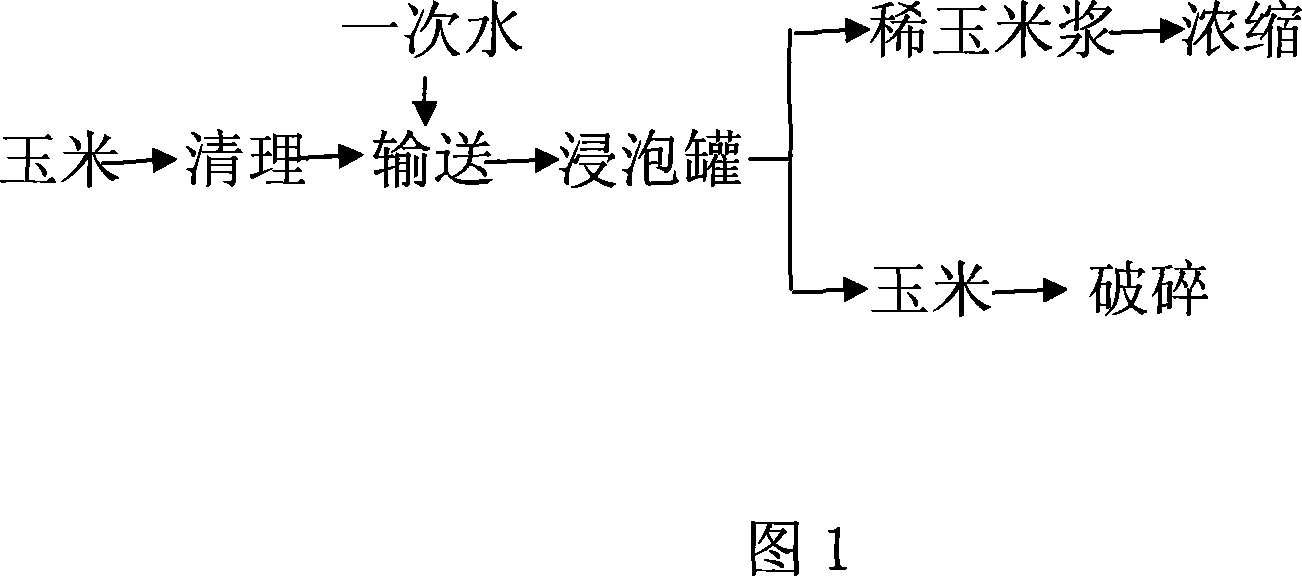

Technology for substituting disposable hydrate transferring raw material with corn slurry

A technology of corn steep liquor and corn soaking water, applied in the field of water saving, which can solve the problems of large amount of waste water and large amount of primary water consumption, and achieve the effects of saving primary water, reducing waste water discharge, and reducing soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

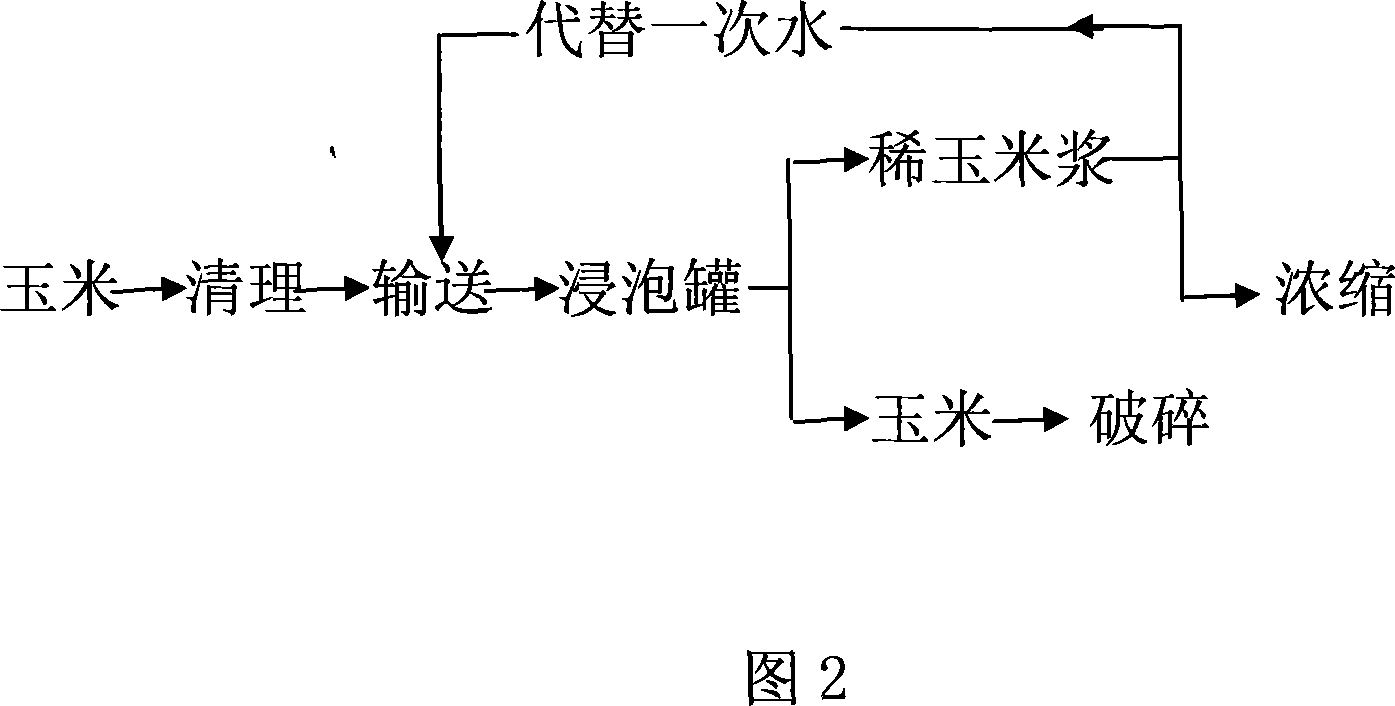

[0013] Corn slurry of the present invention replaces primary water delivery raw material technology, and its technological process is as follows: corn→cleaning→(with thin corn steep liquor) conveying, conveying speed 0.9m / s, 35 ℃, corn: the ratio of thin corn steep liquor is 1: 2.5 → Soak for 72 hours, sulfurous acid concentration 0.2%, temperature 48°C → (corn soaking water) dilute corn syrup contains 7% dry matter, pH value 3.9 → corn transportation. Operation process: Pump the corn soaking water (thin corn steep liquor) that was originally used to further concentrate the production of corn steep liquor to the corn cleaning station, mix it with the cleaned corn, then pump it into the corn soaking tank, and transport it to the corn crushing station. The dilute corn syrup from the corn crushing station is sent back to the enrichment station.

Embodiment 2

[0015] Corn slurry of the present invention replaces primary water delivery raw material technology, and its technological process is as follows: corn→cleaning→(with thin corn steep liquor) conveying, conveying speed 1.0m / s, 38 ℃, corn: the ratio of thin corn steep liquor is 1: 2.8 → Soak for 70 hours, sulfurous acid concentration 0.25%, temperature 50°C → (corn soaking water) dilute corn syrup contains 8% dry matter, pH value 4.0 → corn transportation. Operation process: Pump the corn soaking water (thin corn steep liquor) that was originally used to further concentrate the production of corn steep liquor to the corn cleaning station, mix it with the cleaned corn, then pump it into the corn soaking tank, and transport it to the corn crushing station. The dilute corn syrup from the corn crushing station is sent back to the enrichment station.

Embodiment 3

[0017] Corn slurry of the present invention replaces primary water delivery raw material technology, and its technological process is as follows: corn→cleaning→(with thin corn steep liquor) conveying, conveying speed 1.2m / s, 40 ℃, corn: the ratio of thin corn steep liquor is 1: 3.0→soak for 68 hours, sulfurous acid concentration 0.3%, temperature 52°C→(corn soaking water) dilute corn syrup contains 9% dry matter, pH value 4.1→corn transportation. Operation process: Pump the corn soaking water (thin corn steep liquor) that was originally used to further concentrate the production of corn steep liquor to the corn cleaning station, mix it with the cleaned corn, then pump it into the corn soaking tank, and transport it to the corn crushing station. The dilute corn syrup from the corn crushing station is sent back to the enrichment station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com