Method without templet of preparing leveled macroporous / mesoporous titanium dioxide catalyze material

A technology of mesoporous titanium dioxide and photocatalytic materials, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as expensive, wasteful environment, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

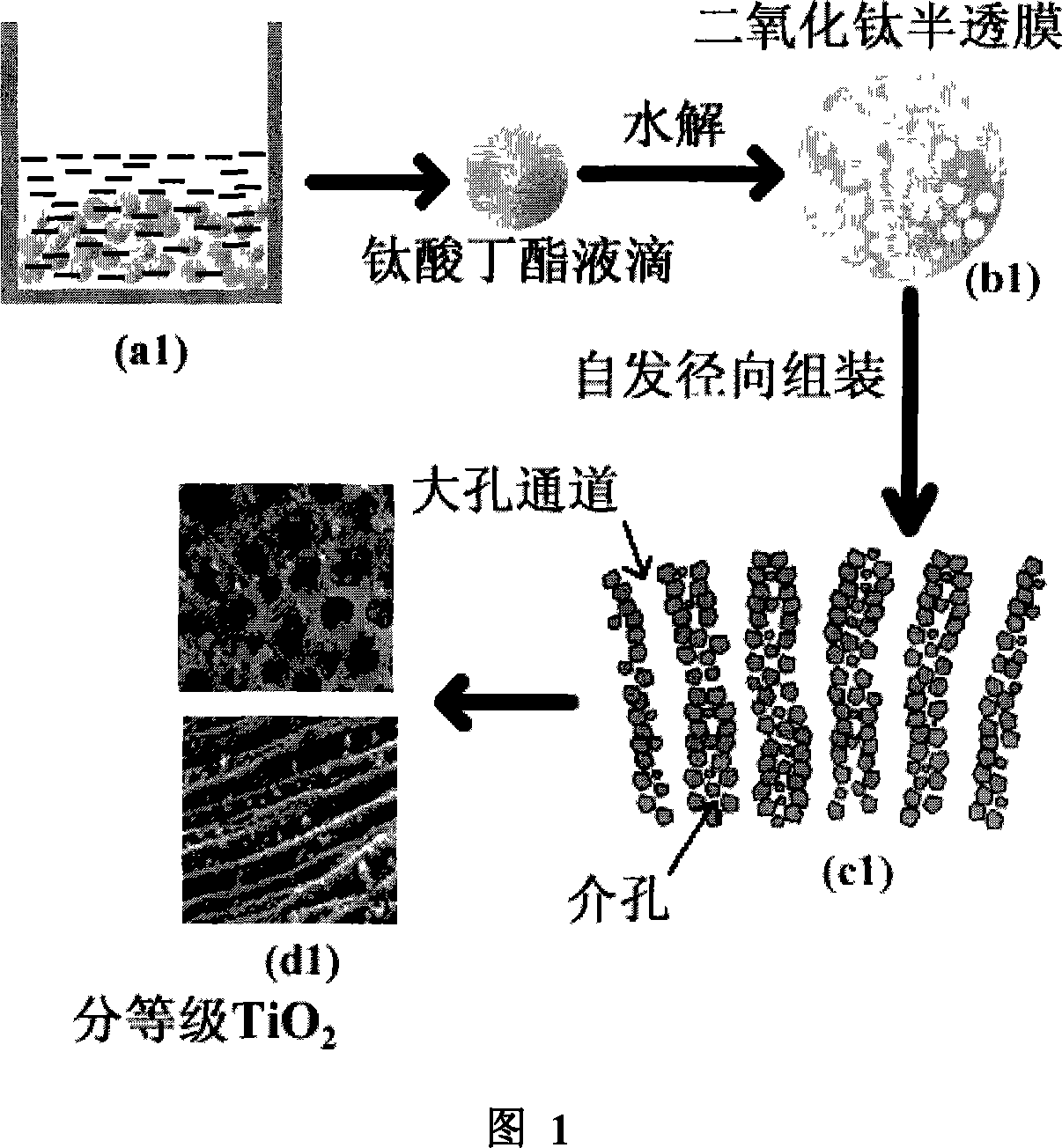

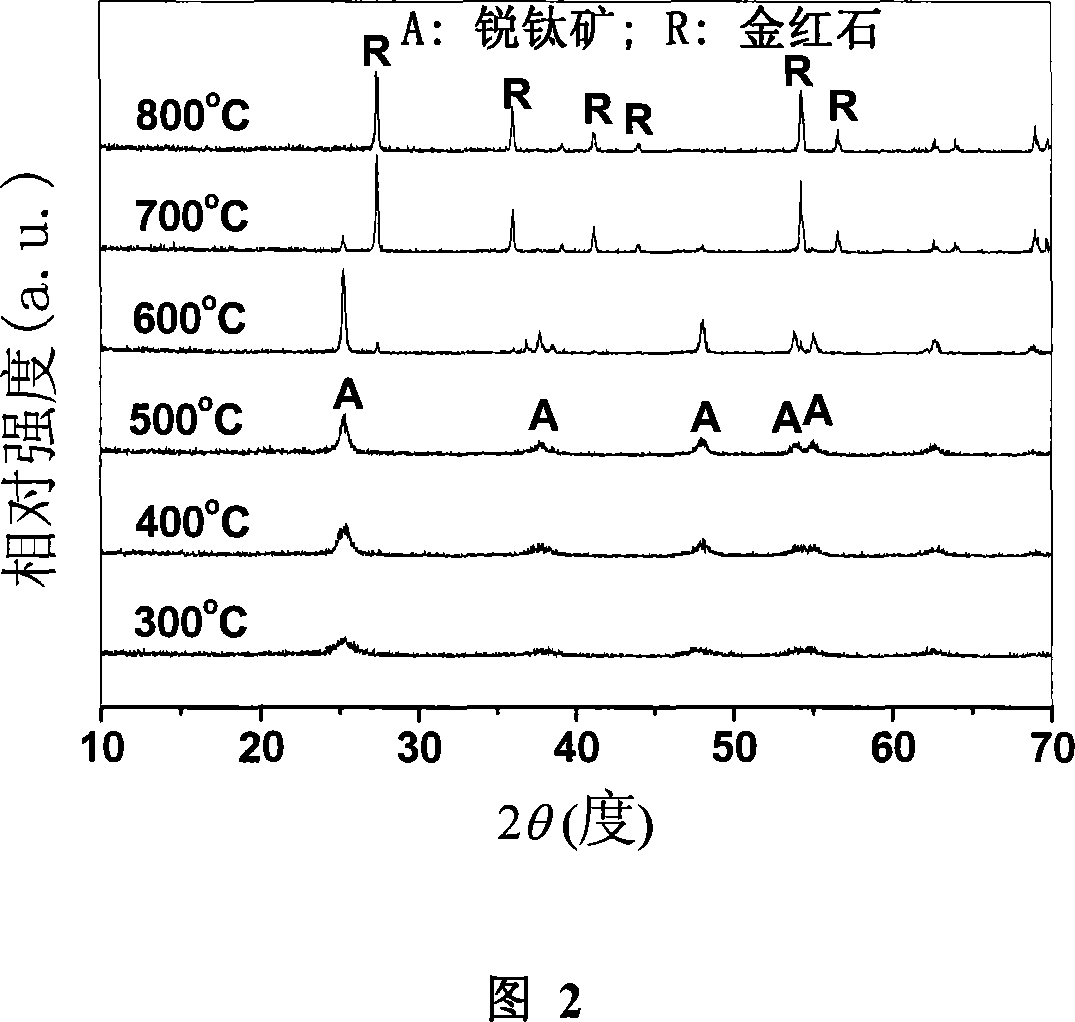

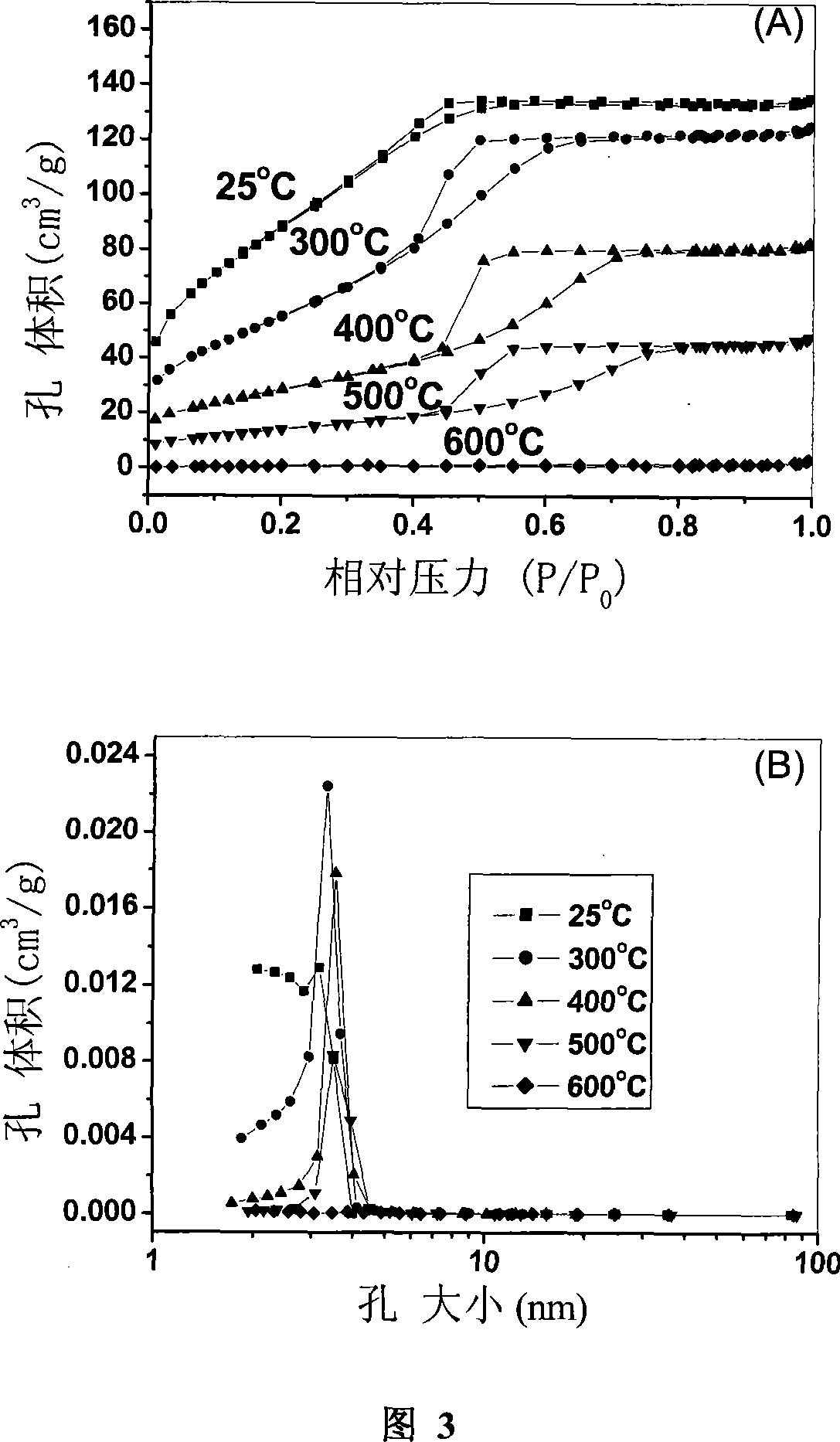

[0025]Graded macroporous / mesoporous titanium dioxide was prepared by adding butyl titanate dropwise to pure water at room temperature, allowing it to be hydrolyzed, aged, then filtered and dried, and finally calcined at different temperatures. The specific experimental process is as follows: 20 ml of butyl titanate was added dropwise to 200 ml of distilled water under static conditions. The molar concentration of butyl titanate is about 0.3M, and the pH value of the reaction solution is 6-7. After aging for 24 hours, the precipitate is separated and washed repeatedly with distilled water, and then dried at normal temperature and pressure for 24 hours. Finally, the prepared white massive spherical particles were calcined at 300, 400, 500, 600, 700 and 800° C. for 1 hour respectively to obtain graded macroporous / mesoporous titanium dioxide. The freshly prepared titania samples were in the amorphous state. Figure 2 shows the TiO 2 From the XRD patterns of the samples calcined a...

Embodiment 2

[0035] In order to examine the effect of the concentration of butyl titanate on the morphology and photocatalytic activity of graded macroporous / mesoporous titanium dioxide, in addition to the different concentrations of butyl titanate, other reaction conditions such as: the pH value of the reaction solution, the hydrolysis temperature of the solution , the reaction time of the solution etc. are all identical with embodiment 1. The results show that when the concentration of butyl titanate is in the range of 0.005-2M, the prepared titanium dioxide samples all present a hierarchical macroporous / mesoporous structure and have good photocatalytic activity. It is found in the experiment that the optimum concentration range of butyl titanate is 0.1-0.8M.

Embodiment 3

[0037] In order to examine the effect of the pH value of the reaction solution on the morphology and photocatalytic activity of the graded macroporous / mesoporous titanium dioxide, in addition to the different pH values of the reaction solution, other reaction conditions such as: the concentration of the reaction solution, the reaction temperature of the solution, the temperature of the solution Reaction time etc. are all identical with embodiment 1. The results show that when the pH value of the reaction solution is higher than 7 (adjusted with ammonia water) and 9, the prepared titanium dioxide samples all present a hierarchical macroporous / mesoporous structure and have good photocatalytic activity. However, when the pH of the reaction solution was lower than 7 (adjusted with hydrochloric acid), the as-prepared titania samples partially exhibited a hierarchical macroporous / mesoporous structure, and the photocatalytic activity of the samples decreased significantly. The opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com