Electron emission source surface activating mould material composition for field-emission display

A technology of electron emission source and material composition, which is applied in the manufacture of circuits, electrical components, electrode systems, etc., and can solve the problems of inability to provide casting film-forming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

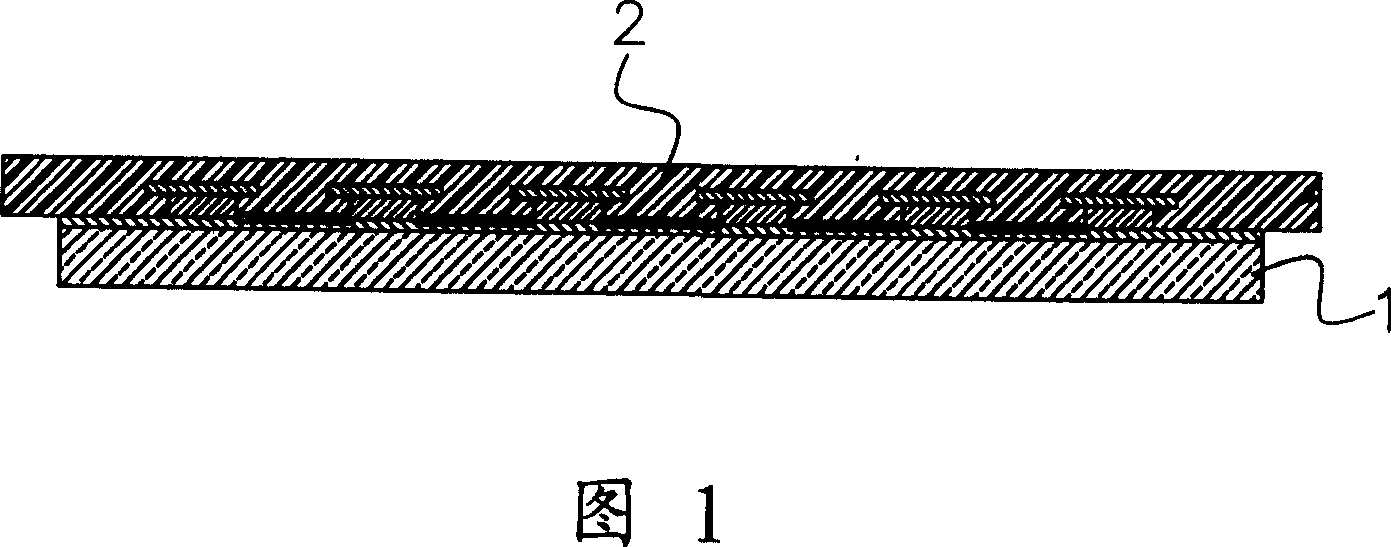

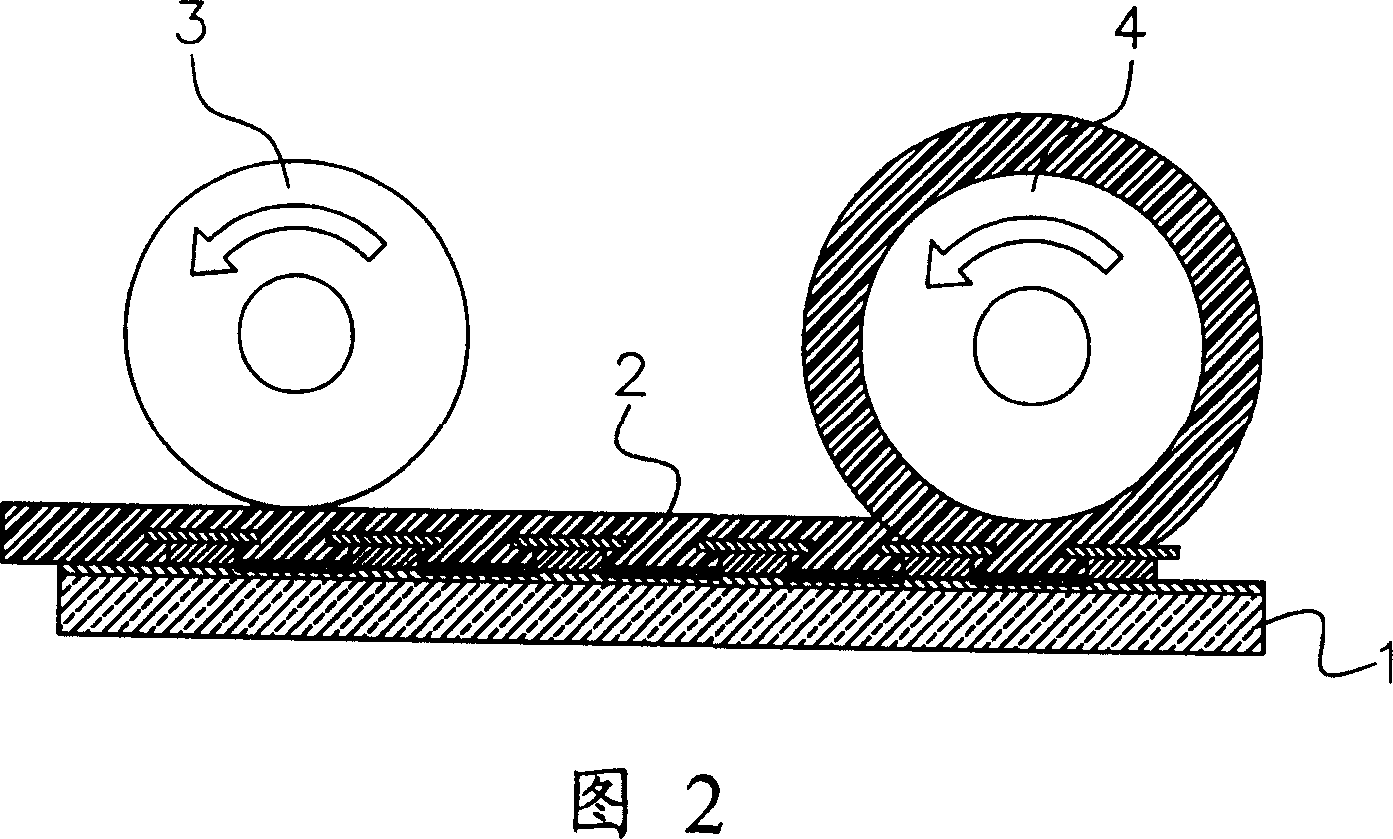

[0016] The technical content and detailed description of the present invention are described as follows with the accompanying drawings:

[0017] The invention relates to a casting material composition for surface activation of an electron emission source of a field emission display. The casting material composition is mainly prepared by selecting an aqueous polyvinyl acetate (PVAc) emulsion to prepare A casting film-forming material that can be applied to the surface activation of electron emission sources, replacing the commonly used PVA or PVP materials. Because the water-based polyvinyl acetate (PVAc) emulsion is solidified at room temperature, it can still maintain elasticity and stretch In addition to the function of sticking and covering, it is beneficial to the application of film stripping. Although this material is beneficial to meet the activation of the surface casting film that can be applied to the electron emission source, it should still meet the requirements of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com