Automatically formed packaging method apparatus for throwing firecrackers

A technology of automatic molding and packaging equipment, which is applied in the direction of offensive equipment, weapon types, pyrotechnics, etc. It can solve the problems of no technical data, low efficiency of manual production, uneven powder content of dropped guns, etc., to improve production efficiency and simple structure , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

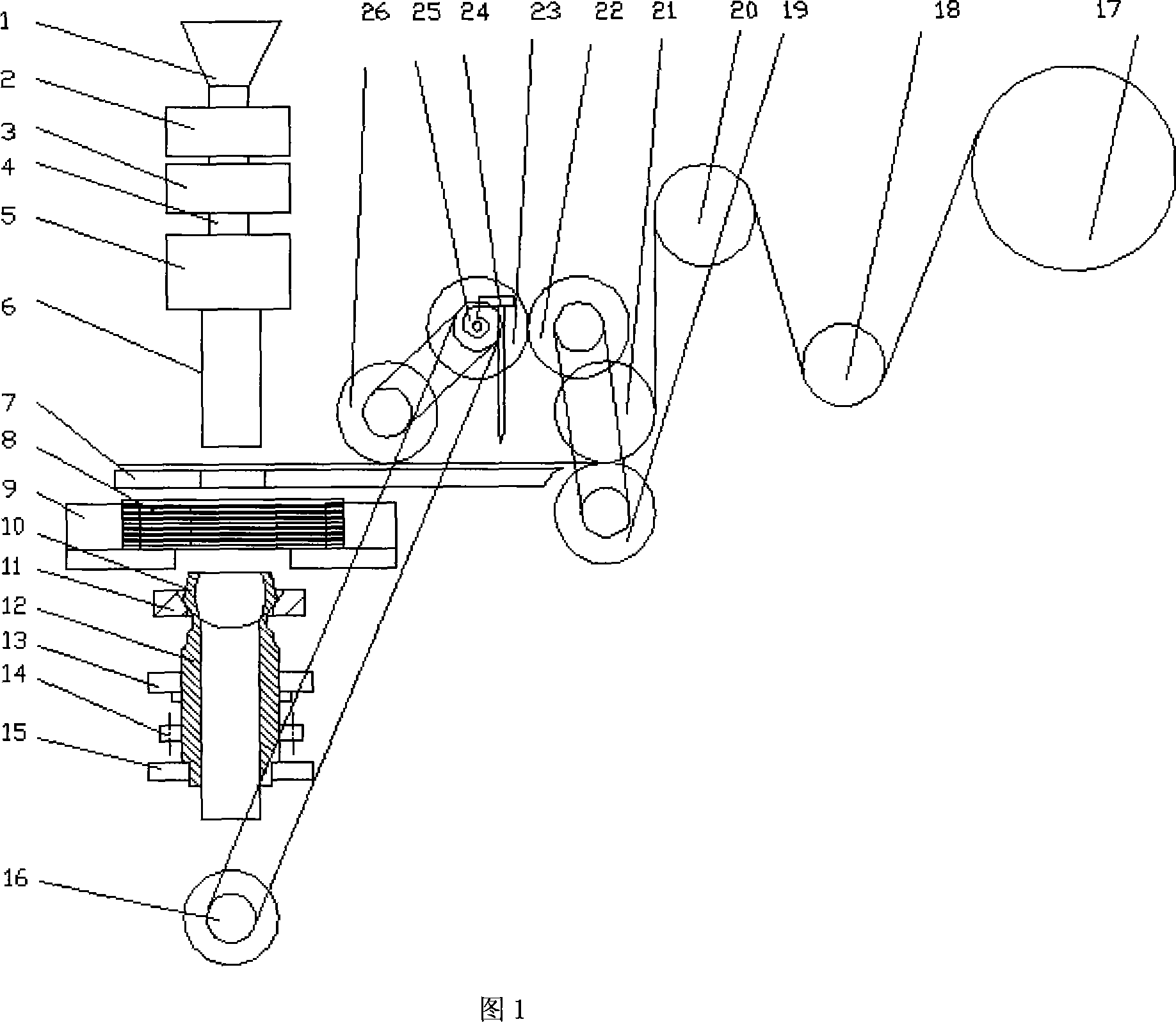

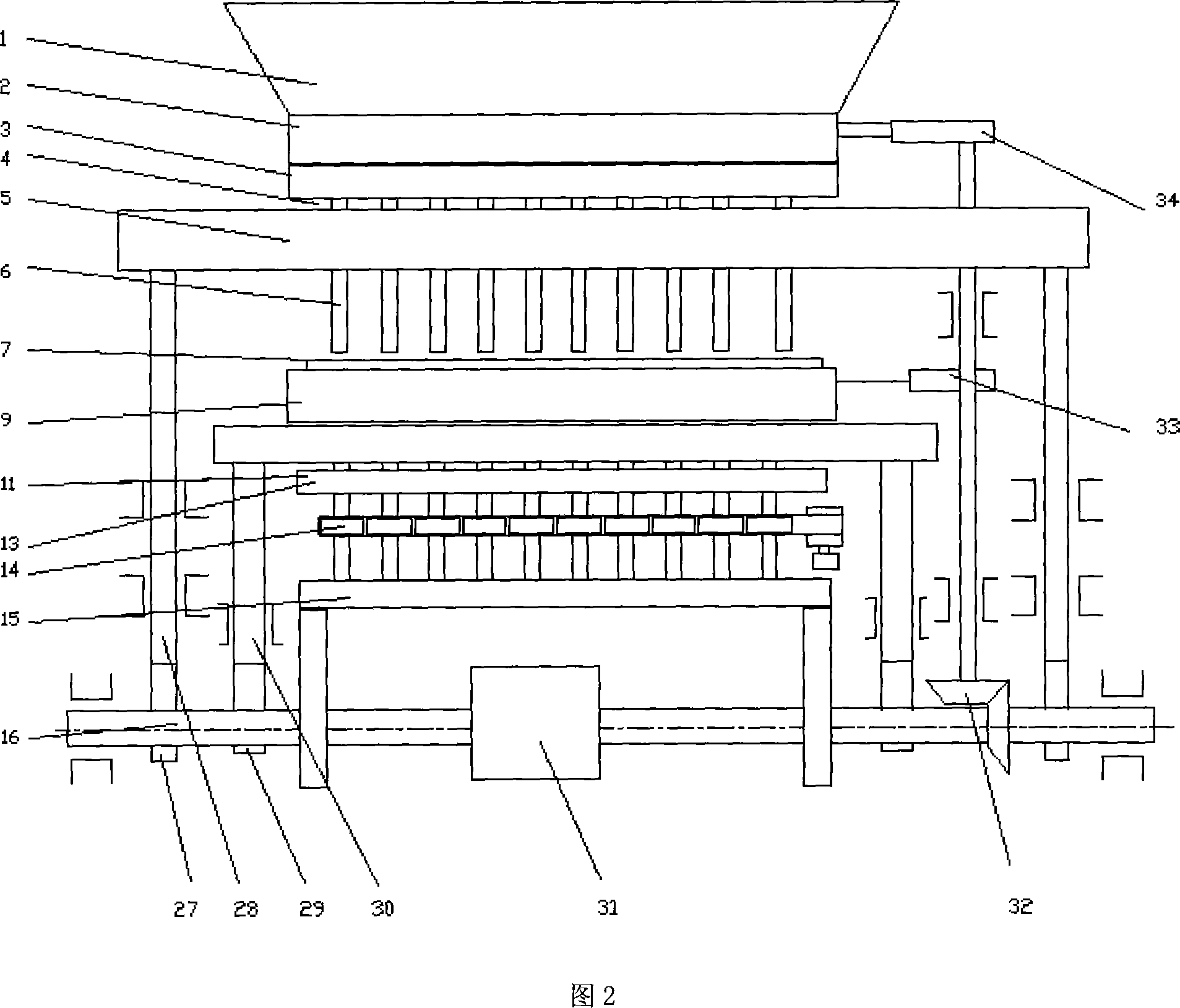

[0012] The accompanying drawing shows an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawing and the embodiment.

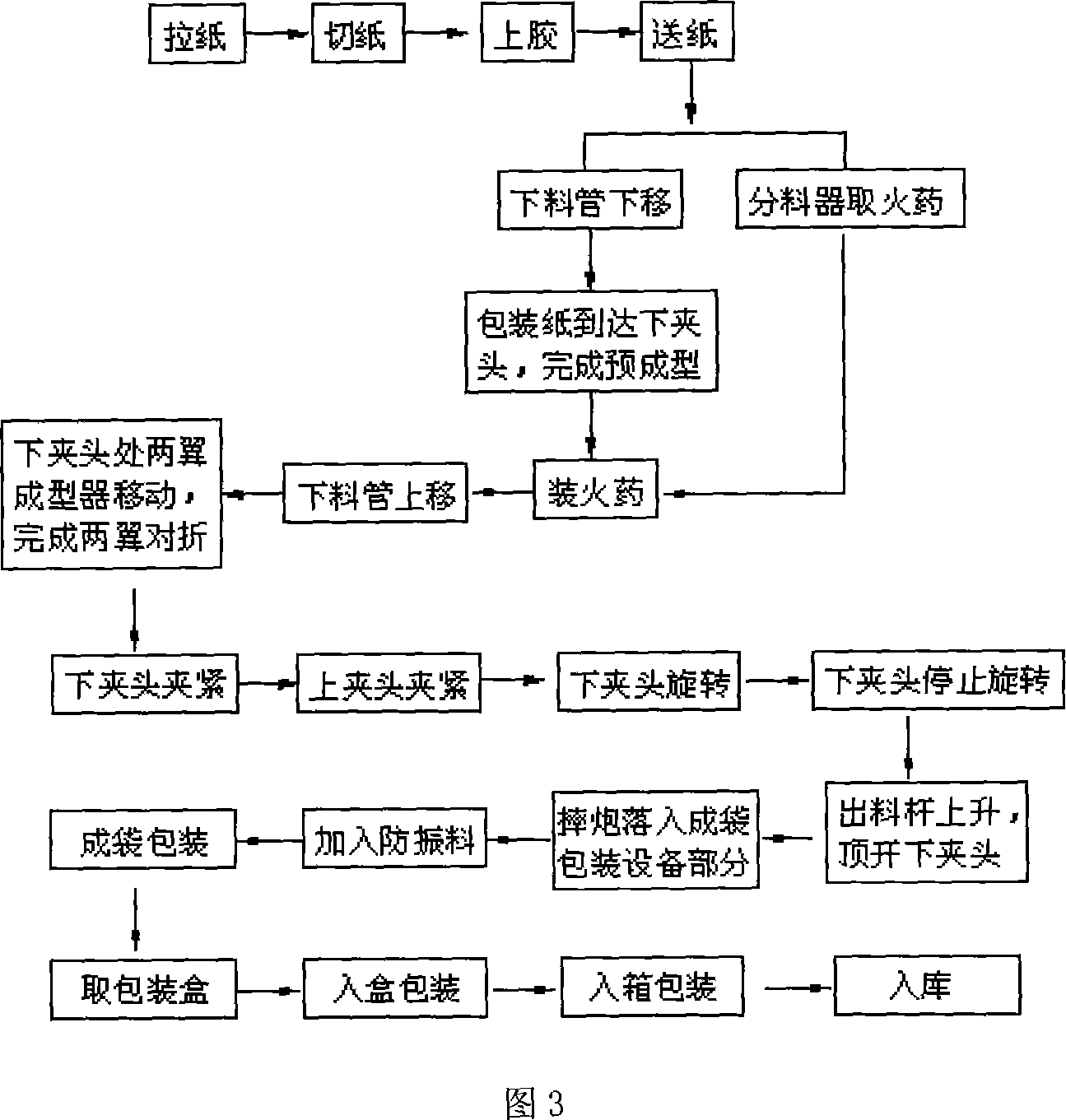

[0013] As can be seen from the accompanying drawings, the present invention adopts imitating manual packaging actions, through a method of paper separation, paper cutting, material distribution, paper forming, blanking, clamping the lower chuck, clamping the upper chuck, rotation, The mechanical equipment of opening the upper chuck, opening the lower chuck, opening the chuck tongue, blanking, and chuck tongue tightening mechanism replaces the manual method. It can automatically complete the packing of the cannon forming, including paper pulling, paper cutting, paper feeding, stamping, material distribution, clamping the upper chuck, clamping the lower chuck, rotating the lower chuck, releasing the upper chuck, and loosening the lower chuck. A complete set of packaging actions s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com