Working head for mowing grass

A grass cutting head and working head technology, which is applied to lawn mowers, cutters, agricultural machinery and implements, etc., can solve problems such as being unsuitable for field work, and achieve the effects of extending length, convenient use and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

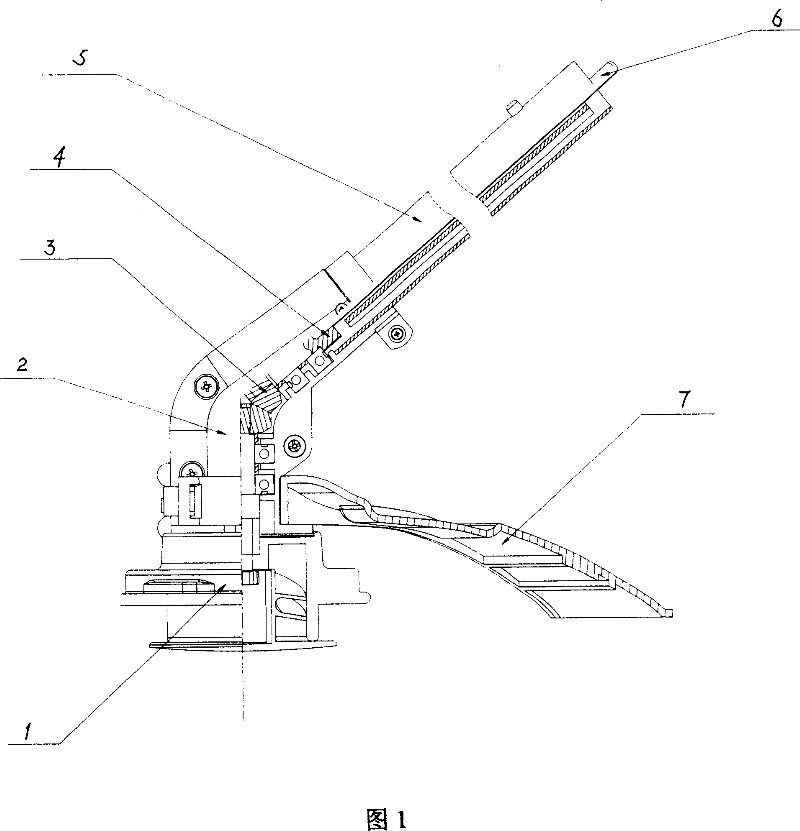

[0011] As shown in Figure 1, it is a structural schematic diagram of the weeding working head, and the described weeding working head is made up of a weeding head 1, a gear box 2, a gear 3, a shaft 4, a steel pipe 5, a flexible shaft 6, and a protective cover 7, which can be The mowing head 1 of rotation is connected with gear box 2, and the gear 3 in the gear box 2 is connected with the shaft 4 in the steel pipe 5, and the shaft 4 is connected with the rotatable flexible shaft 6, and protective cover 7 is installed outside the gear box 2.

[0012] When in use, the flexible shaft 6 is driven by a small gasoline engine to rotate, and the flexible shaft 6 transmits the power to the shaft 4, and then to the gear 3, and finally drives the weeding head 1 to rotate to remove weeds. According to different work requirements and the range of weeding , can replace the mowing head 1, easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com