Dried fluorine aluminum powder cooling and conveying process

An aluminum fluoride, dry process technology, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems of low cooling efficiency, increased moisture content of aluminum fluoride, and high dew point of compressed air, so as to improve the quality of finished products and improve cooling efficiency , The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

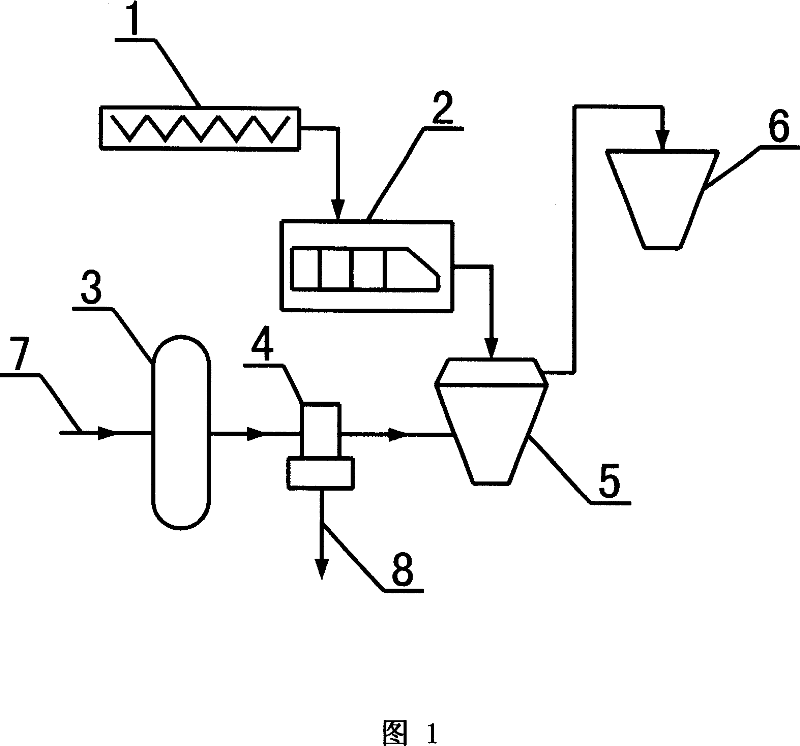

[0016] A cooling and conveying process for dry-process aluminum fluoride powder. Aluminum fluoride enters the fluidized cooler 2 from the aluminum fluoride conveying screw 1 and uses water cooling to exchange heat. After heat exchange, the cooling water returns to the circulating water system; after cooling The finished aluminum fluoride is transported to the aluminum fluoride bin 6 by the pneumatic conveying pump 5 .

[0017] The compressed air used by the pneumatic conveying pump 5 is sent by the compressed air pipeline 7. The compressed air first enters the compressed air storage tank 3 for storage, and then the moisture and oil in the compressed air are removed through the compressed air drying filter 4, and the dried Compressed air enters the pneumatic conveying pump 5 to convey dry-process aluminum fluoride powder. Moisture and greasy dirt removed by compressed air drying filter 4 are discharged by drain pipe 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com