Gas generation-storage integral anaerobic zymosis device

An anaerobic fermentation and gas storage technology, which is applied in biological sludge treatment, waste fuel, etc., can solve the problems of crusting, easy acidification, scum, etc., and achieve high fermentation gas production efficiency, good heat preservation performance, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

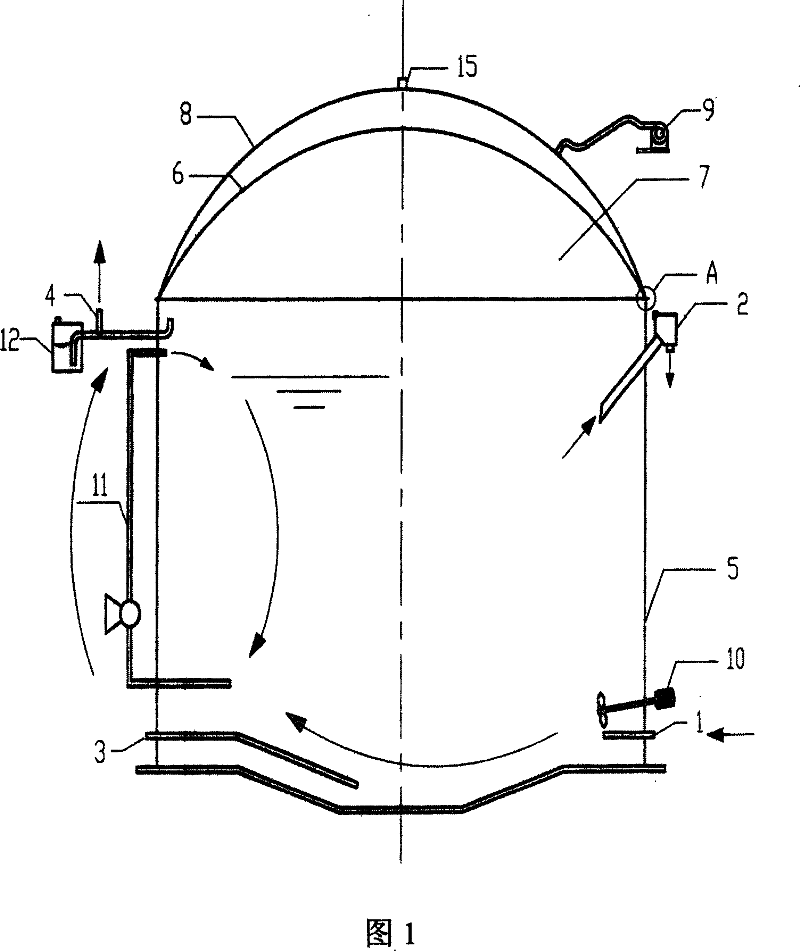

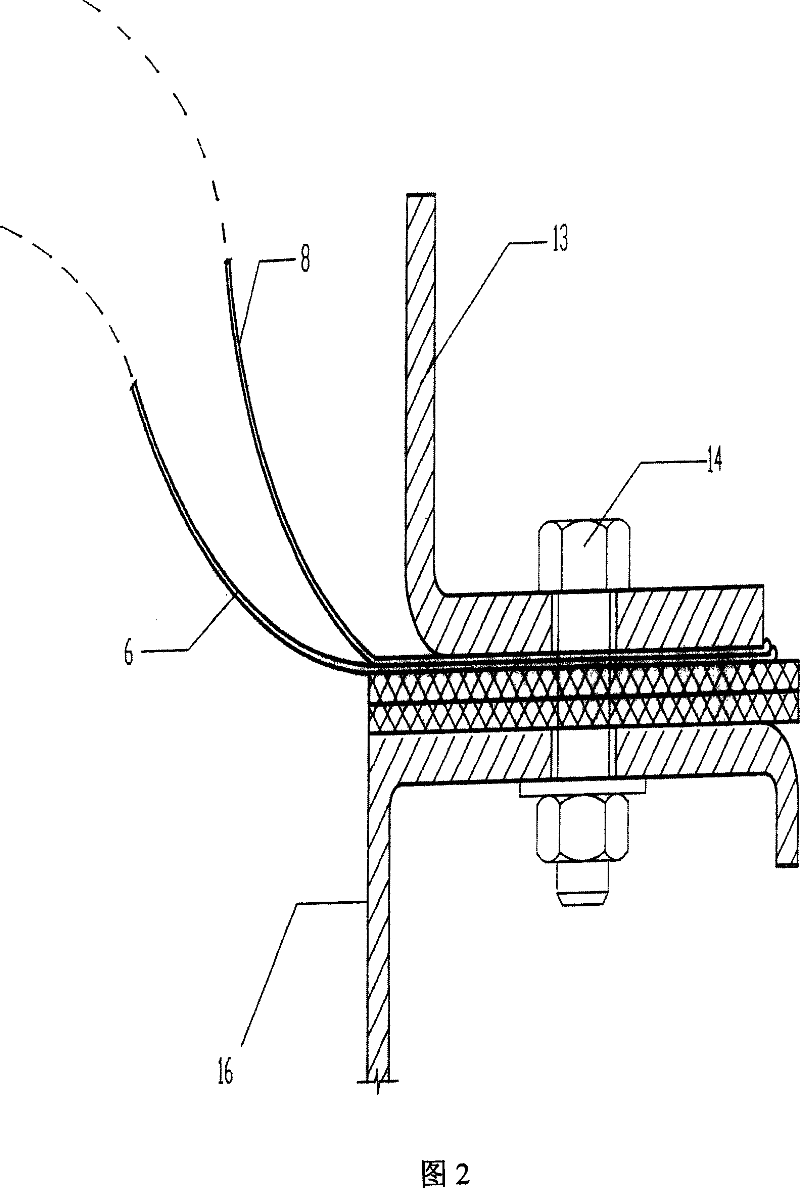

[0020] Example 1. As shown in Figure 1, the integrated anaerobic fermentation device for gas production and gas storage of the present invention has a cylindrical tank body 5 of a PVC composite film, and the tank body is provided with a feed port 1, a discharge port 2, and a slag discharge port 3 With the biogas outlet 4, the biogas outlet is connected with a safety water seal 12 in parallel. The outermost part of the tank roof is a PVC composite film hemispherical pressurized film 8 to form a spherical crown; There is a PVC composite membrane flexible air storage membrane 6 in the spherical crown, and a sealed chamber is formed between the two layers of membranes. The upper edge 16 of the tank body 5 has a matching annular fastening bead 13, and the bolt 14 passes through the compression block to compress the air storage film 6 and the pressurized film 8 on the edge through the sealing plate 17 to achieve airtightness (see figure 2). An air storage chamber 7 is formed betw...

Embodiment 2

[0028] Example 2. The bottom of the tank body of this example fermentation device is concave, and the rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com